THE UPKEEP OF STEAM WAGONS.

Page 15

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

No. 14.—Overhaul and Repairs. Frame and Water Tank, Wheels, Body, Etc.

The most faequent defect in a frame is a cracked or broken side member. The side members are practically all made from rolled channel sections of goodquality steel, but they are very severely stressed owing to the heavy load, vibratiortand twisting caused by uneven road surfaces. It will invariably be found that the fracture has occurred through a bolt hole, where a bracket is fixed to the frame, such as the radius rod bracket. In many cases it is the design of the frame that is at fault, the stay plates not being suitably proportioned, or too many bolt holes are arranged close together. Another bad defect is to be found in the drilling of bolt holes in the top or bottom flanges of the channel. This should never be done ; the bolt holes should always be arranged in the vertical web of the channel and as near the centre as possible. Breakages in frames can be satisfactorily repaired by welding with oxy-acetylene ; but, as a rule, it is advisable to back up the portion of the frame in the vicinity of the repair with a plate. " A breakage in a frame is FL sign of weakness, duo, more often than not, to unfair distribution of the load. A frame should always be repaired as soon as a crack is observed, and not left until the channel is broken right through, for, in this event, it is extremely difficult to reset the frame correctly when repairing.

The most simple repair is illustrated in Fig. 60. Chip out all the cracked part in the shape of a V groove ; then clamp a stiff bar on the channel to pull it up straight, and weld up the groove. The excess metal at the weld should then be filed off to the same thickness as the section of the channel. A piece of mild-steel plate, in. thick and wide enough to be a good tight fit between the flanges, and about 3 ft. Tong, should then be procured. The exact length will, of .course, depend upon the position of the fracture in relation to other parts fixed on the. frame. The two edges of the plate must be radiused tosuit the corners inside the channel, and it is Very important that the plate should fit tightly between the flanges at A and B. The plate should also be tapered off at each end, as shown in plan at 0, in order to avoid an abrupt change in the strength of the frame. Two rows of holes should be drilled, about 6 ins, pitch and staggered as shown, and turned bolts fitted with the ends

riveted over the nuts. These bolts must be a tight driving fit or the repair will not-be successful. If the frame is dismantled, then rivets should be used in preference to bolts.

If a frame should break at a point beyond the stay plate, as shown in Fig. 61,, to make a. satisfactory job, in addition to welding up the crack the side plates should be extended, as shown in Fig. 62. These new plates slfould extend up to the forward housing of the hind spring and be riveted to the frame with a riveted butt joint with cover plate inside, as shown in the illustration. Of course, much .depends upon the state a the frame, and, if it' s very badly damaged, it may be necessary to fit new side channels. Al! rivets and bolts connecting the frame to the boiler and fixing brackets should be carefully examined, and if any are found loose they should be replaced. Never use smaller rivets than k in. or the heads will snap off, and all bolts should be riveted over the nuts, or fitted with castle nuts. The Most vital part of 'aframe is between the forward housing of the hind spring and the point where the frame is attached, to the boiler. It is here where defects should 'be looked for.

• An examination of the water tank'should be made to ascertain if any part is damaged. If it should prove to be so, cut out the had part and fit on a patch. These patches are best riveted on, buteif bolts have.to be used put grummets made of tarband and red lead under the, bolt heads inside the tank. Many tanks get damaged because they are too rigidly attached to the frame, the .deflection of the frame causing the tank to be twisted.

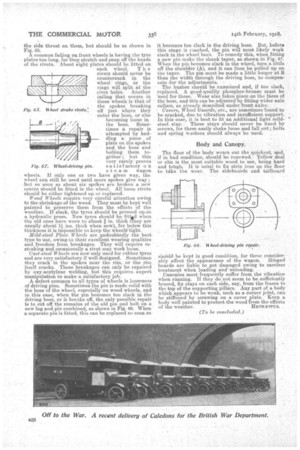

If a tank is suspended by wood beams and bolts, as shown in Fig. 63, the beamsand bolts wear theaolates away by the continual rubbing due to vibralion. A better method of suspending a tank is as shown in Fig: 64. The straps are riveted to the tank to 1:o/event " them rubbing into the plates ; also if the top bolts 'break it is a simple matter to replace them. The bottom of a tank is most likely to crack first, owing to the weight of the water above it.

Stays are usually fitted inside a tank to support, the bottom, and these are liable to get broken, -duel° the wash of the water. So soon as any part of these stays breaks or becomes loose, repair it, for if left, thtaimeven strain is likeIrbadly to'damage the other parts.

Wheels.

The repairs to the various ,types of .viaeels used on steam wagons can be summarized as follows :— Traction-engine Type.—The most common repair necessitated is the fitting of new strokes or shoes. These should all be made to template, to suit the hole-s in the -Wheel rings, and must be about a in narrower than the rings, to allow for spreading out. They are then made hot and bedded on the wheels •,by bolting them on and hammering down, afterwards riveting them on with rivas.counteraunkin the strakes. The counteTsinking should-not extend the full depth of the strake, or the-rivets will soon become loose owinAto

the side thrust on them, but should be as shown in Fig. 65.

A common failing on front wheels is having the tyre plates too long, for they stretch and snap off the heads of the rivets. About eight plates should be fitted on each wheel. T b e rivets should never be countersunk in the wheel rings, or the rings will split at' the rivet holes. Another tailing that occurs in these wheels is that of the spokes breaking off just where they enter the boss, or else becoming loose in, the boss. Soinetimes a repair is attempted by bedding a piece of plate on the spokes and the boss and bolting them together; but this very rarely proves S team wagon wheels, If only one or two have given way, the wheel can still be used until more spokes give way ; • but so soon as about six spoke s are broken a new centre should be fitted in the wheel. All loose rivets should be either tightened up or replaced.

• Wood Wheels require very careful attention owing to the shrinkage of the wood. They must be kept well painted to preserve them from the effects of the weather. If slack, the tyres should be pressed up.in a hydraulic press. New tyres should be fittad when the old ones have worn to about t in. thick (they are

• usually about LI. ins, thick when new), for below this thickness it is impossible to keep the wheelg'tight.

Mild-steel Plate Wheels are undoubtedly the besttype to use, owing to their excellent wearing qualities and freedom from breakages. They will require restraking and occasionally a rivet may work loose. Cast-steel Wheels are now only used for rubber tyres and are very satisfactory if well designed. Sometimes they track in the spokes near the rim, or the rim itself cracks. These breakages can only be repaired by oxy-acetylene welding, but this requires expert manipulation to make a satisfactory job.

A defect common to all types of wheels is looseness of driving pins. Sometimes the pin is made solid with the boss of the wheel, especially on wood wheels, and in this case, when the pin becomes too slack in the driving boss, or it breaks off, the only possible repair is to cut off the remains of the old pin and bolt on a new lug and pin combined, as shown in Fig, 66. When a separate pin is fitted, this can be replaced so soon as it becomes too slack in the driving boss. But, before this stage is reached, the pin will most likely wo,rk slack in the wheel boss. To remedy this, when fitting a new pin make the shank taper, as shown in Fig. 67. When the pin becomes slack in the wheel, turn a little off the shoulder (A), and it can then be pulled up on the taper. The pin must be made a little longer at B than the width through the driving boss, to compensate for the adjustments. • The bushes should be examined and, if too slack, replaced. A good-quality phosphor-bronze must be used for these. Wear also takes place on the faces of the hots, and this can be adjusted by fitting wider axle collars, as already described under front axles.

• Covers, Wheel Guards etc., are sometimes found to be cracked, due to vibration and insufficient support. In this case, it is best to fit an additional light mildsteel. stay. These stays should never be fixed by screws, for these easily shake loose and fall out ; bolts and spring washers should always be used.

Body and Canopy.

The floor of the body wears out the quickest, and, if in bad condition, should be 1-enewed. Yellow deal Or elm is the most suitable wood to use, being hard and toligh. It is usual to fix strip iron on the floor to take the wear. The sideboards and tailboard sheuld be kept in good condition, for these considerably affect the appearance of the wagon. Hinged boards are liable to get damaged owing to careless treatment when loading and unloading.

Canopies most frequently suffer from the vibration when running. If they do not seem to be sufficiently braced, fix stays on each side, say, from the frame to the top of the supporting pillars. Any part of a body which appears to be weak, such as a corner joint, can be stiffened by screwing on a cover plate. • Keep a body well painted to protect the wood from the effects

of the weather. REPH/ESTUS.