The Adams Self-starter.

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

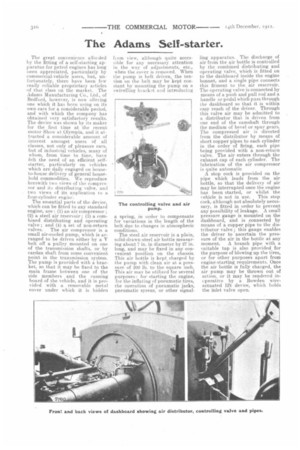

The great convenience affouled by the fitting of a self-starting a.pparatus for petrol engines has long bee ii appreciated, particularly by commercial-vehicle users, but, unfortunately, there have been few really reliable proprietary articles of thai class on the market. The Adams Manufacturing Co., Ltd., of Bedford, however, is now offeiing one which it has been using on its own cars for a considerable period, and with which the company has obtained very satisfactory results, The device was shown by its maker for the first time at the recent motor Show at Olympia, and it attracted a considerable amount of interest amongst users of all classes, not only of pleasure ears, but of industrial vehicles, many of whom, from time to time, have felt the need of an efficient selfstarter, particularly on vehicles which are daily engaged on houseto-house delivery of general household commodities. We reproduce herewith two views of the campres sor and its distributing valve. and two views of its application to a four-cylinder engine.

The essential parts of the device, which can be fitted to any standard engine, are : (1) an air compressor ; (2) a steel air reservoir ; (3) a combined distributing and operating valve ; and (4) a set of non-return

valves. The air compressor is a small air-cooled pump, which is arranged to be driven either by a V belt off a pulley mounted on one of the transmission shafts, or by cardan. shaft from some convenient point in the transmission system. l'he pump is provided with a bracket, so that it may be fixed to the main frame between one of the side members and the running board of the vehicle, and it is provided with a, removable metal cover under which it is hidden

orn view, although quite accessible for any necessary attention, in the way of adjustments, etc., when the cover is removed. When the pump is belt driven, the tension on the belt may be kept constant by mounting the pump on a swivelling bracket, and introducing a spring, in order to compensate for variations in the length of the belt due to changes in atmospheric conditions.

The steel air reservoir is a plain, solid-drawn-steel air bottle measuring about 7 in. in diameter by 27 in. long, and may be fixed in any convenient position on the chassis. This air bottle is kept charged by the pump with clean air at a pressure of 200 lb. to the square inch. This air may be utilized for several purposes: for starting the engine, for the inflating of pneumatic tires, the operation of pneumatic jacks, pneumatic syrens, or other signal ling apparatus. The discharge of air from the air bottle is controlled by the combined distributing and operating valve, which is fitted on to the dashboard inside the engine bonnet, and a single pipe connects this fitment to the air reservoir. The operating valve is connected by means of a push and pull rod and a handle or pedal which pass through the dashboard so that it is within easy reach of the driver. Through this valve air may be admitted to a distributor that is driven from one end of the camshaft through the medium of bevel or spur gears. The compressed air is directed. from the distributor by means of short copper pipes to each cylinder in the order of firing, each pipe being provided with a non-return valve. The air enters through the exhaust.cap of each cylinder. The lubrication of the air compressor is quite automatic.

A stop cock is provided on the pipe which leads from the air bottle, so that the delivery of air may be interrupted once the engine has been started, or whilst the

vehicle is not in use. This stop cock, although not absolutely necessary, is fitted in order to prevent any possibility of leakage. A small pressure gauge is mounted on the dashboard, and is connected by means of a copper pipe to the distributor valve ; this gauge enables the driver to ascertain the pressure of the air in the bottle at any moment. A branch pipe with a suitable tap is also provided for the purpose of blowing up the tires, or for other purposes apart from engine-starting requirements. Once the air bottle is fully charged, the air .pump may be thrown out of action, or it may be rendered inoperative by a Bowden wireactuated lift device, which holds the inlet valve open.