AIDS TO SOLVING FORD PROBLEMS.

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

Valuable Advice on Every Phase of Ford Transport, which will Appeal to the Owner, Driver, and Repairer.

IN THIS series of hints concerning the Ford light chassis 'and ton truck' wherever they are employed for commercial purposes we endeavour to deal with the subject from every view-point, so that the advice given will appeal to the owner, driver, maintenance engineer, or mechanic. Valuable sources of information are being tapped for this purpose, and it should be understood that the information given will be derived from those with an intimate knowledge of the subject.

We shall welcome for inclusion among the hints those which have proved of value to individual users, and will make suitable remuneration for any published. What we desire are the results of practice.

82.---Improving the Ford Steering and Engine Controls.

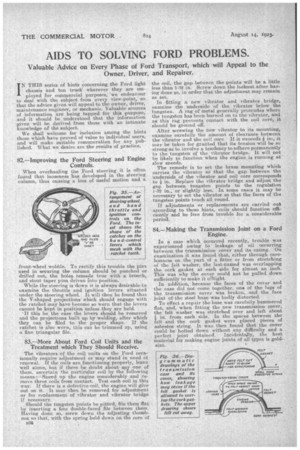

When overhauling the Ford steering it is often found that looseness has developed in the steering column, thus causing a loss of useful motion and a front-wheel wobble. Te rectify this trouble the pins used in securing the column should be punched or drilled out, the holes remade true with a brooch, and stout taper pins driven into position. While the steering is down it is always desirable to examine the throttle and ignition levers situated under the steering wheel. It will then be found that the V-shaped projections' which should engage with the ratchet may have become so worn that the levers cannot be kept in position unless they are held. 'If this be the case the levers should be removed and the projections built up by welding, after which they can be filed to the proper shape. If the ratchet, is also worn, this can be trimmed up, using a fine triangular file.

83.—More About Ford Coil Units and the Treatment which They Should Receive.

The vibrators Of the coil units on the Ford nemsaonally require a.djustment or may stand in need of renewal. If the coils are functioning properly, leave 'well alone, but if there be doubt about any one of them. ascertain the particular coil by the following means:—Speed up the engine considerably and remove three coils from contact. Test each coil in this way. If there is a defective coil, the engine will give out on it. It may then be removed for adjustment or for renlacement of vibrator and vibrator bridge if necessary.

Should the tungsten points he pitted, file them flat by inserting a fine double-faced between them. Having done so, screw down the adjusting thumbnut so that, with the spring held down on the core of n3S • the coil, the gap between the points will be a little less than 1-32 in. Screw down the locknut after having done so, in order that the adjustment may remain as set.

In fitting a new vibrator and vibrator bridge, examine the underside of the vibrator below the tungsten. A rag of metal generally protrudes where the tungsten has been burned on to the vibrator, and as this rag prevents contact with the coil core, it should be ground off.

After screwing the new vibrator to its mounting, examine carefully the amount of clearance between the vibrator and the coil core. If it exceeds in., it may be taken for granted that its tension will be so strong as to involve a tendency to adhere permanently to the tungsten of the vibrator bridge. It will not • be likely to function when the engine, is running at' slow speeds.

The remedy is to set the brass mounting which carries the vibrator se that the gap between the underside of the vibrator and coil core corresponds to in. Replace the vibrator bridge and adjust the gap between tungsten points to the regulation 1-32 in., -or slightly less. In some cases it may be necessary to set the vibrator so that the faces of the tungsten points touch all round.

If adjustments or replacements are carried out according to these hints, coils should function efficiently .and be free from trouble for a considerable period.

84.—Making the Transmission Joint on a Ford

Engine.

In a case which occurred recently, trouble was experienced owing to leakage of oil occurring between the transmission cover and its casing. On examination it was found that, either through carelessness on the part of a fitter or from stretching of the felt washer, the last-named was overlapping the cork gasket at each side for almost an inch. This was why the cover could not be pulled down sufficiently to make it °Might.

In addition, because the faces of the cover and the case did not come together, one of the lugs of the transmission cover was broken, and the face joint of-the steel base was badly distorted.

To effect a repair the base was carefully hammered flat, and, when fitting the new transmission cover, the felt washer was stretched over and left about in. from each side. In the spaces between the felt and the cork gasket were placed pieces of asbestos string. It was then found that the cover could be bolted down without any difficulty and a perfect joint obtained. Incidentally, the best material for making engine joints of all types is gold. size.