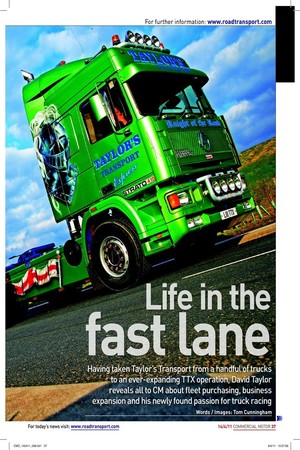

Life in the

Page 25

Page 26

Page 27

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

ast lane

Having taken Taylor’s Transport from a handful of trucks to an ever-expanding TTX operation, David Taylor reveals all to CM about fleet purchasing, business expansion and his newly found passion for truck racing

Words / Images: Tom Cunningham “This new building sits on what was once part of the Seddon Atkinson factory complex – and I served my apprenticeship over the back there,” Taylor remarks, pointing through a window behind his desk. Pleasant and extremely down to earth, he’s a man with a strong local belonging. If you’ve been connected with the British road transport industry (in any way) over the past 40 or 50 years or so, then Woodstock will mean more than the 1969 music festival held in New York State. “I started here as a toolmaker straight from school,” he recalls.

At the time, his father Malcolm ran a small transport business from the other side of town, which Taylor later joined at 21. “Originally the business was set up as a recycling operation, to handle commodities like cardboard and locally processed cotton, but it quickly had direction to became a haulage business,” he recalls. Under Taylor’s control, out went white and in came lime green and big dark blue letters, where all but the visually challenged can’t help but notice the bold brand parked in front of them. When Iveco announced the closure of parent company Seddon Atkinson Vehicles back in 2004, the news wouldn’t have passed the ears of Taylor without stopping. “Members of the Howarth family bought the biggest bit of what was once the truck plant and ofices, but we managed to snap up the bit at the back. I don’t want to make this sound gushing in any way, but this does feel like the spiritual home of an Oldham-based transport company,” he states.

What a difference a decade makes

The Woodstock-based leet now numbers 70 trucks and more than 120 trailers, which has grown from just over 20 this time 10 years ago. The irm’s core business is the delivery of white goods and plastic moulded parts from a number of local manufacturers on a direct to RDC or direct to store basis. The business operates a 120,000ft2 warehouse facility on the other side of Oldham, where it also unloads deep sea containers for storage and repack

ing. The business employs over 120 staff, with just under 100 drivers, and the remainder split between ofice staff and workshop technicians.

Renault forms the backbone of the TTX line up, with smaller numbers from the likes of DAF, Iveco and Mercedes-Benz, bought because Taylor says “the deal was right” . He recalls a statement his late father, Malcolm, once made: “We’ll never have a Renault in this yard.” As we stand in the yard glancing across the rows and rows of tractors bearing the silver diamond badge, it’s hard to see how he could have been so wrong. “We started buying Renault in big numbers initially because JDS Trucks supported my son Luke when he was searching for an apprenticeship place. Today Renault makes a very good product. It’s light, easy to work on and driver friendly. It’s an excellent leet truck and a decision we’ve never regretted,” he enthuses. TTX does operate a number of larger Magnum tractors, but the current preferred purchasing spec would be three to four-year-old used Premium Privilege in 6x2 form, which TTX runs for a further threeor four-year period.

“We tend to make the main dealer network our irst port of call when buying trucks, although we don’t normally buy any kind of used warranty package.” David’s closest sales dealer in the network is JDS Trucks, which has a facility just outside central Manchester at Salford Quays. “The relationship we’ve got with everyone at JDS is such that if an issue arises, a quick phone call normally sorts it,” he adds.

Three trucks for the price of one

Have you ever considered the likes of Volvo or Scania? “Yes, but in the current climate they’re way too pricy. The local Scania dealer has recently been offering a threeyear-old R-series Topline. Granted, it’s got a big cab, big engine, extremely low mileage with all the bells and whistles. The asking price is £72,000. For that amount of cash I could add three decent Renault Premiums to the leet, which at the end of the day would potentially earn us three times the revenue of the single Scania. I would say the Swedes are good, but they’re not that good,” Taylor argues.

Fleet repairs are carried out by one of TTX’s 12 technicians in the irm’s purpose-built ive-bay workshop. The company also operates its own breakdown vehicle, which Taylor reckons could recover a stricken truck in a radius stretching out as far north as Carlisle and as far south as Birmingham. “These days, the number one cause of VOR is self-inlicted damage, not, as one might think, component wear. The technology and materials we use to build our modern diesel engines, for example, means the units are good for over a million kilometres,” he insists.

At the time of our visit, the company was engaged in an intensive study process that would see the procurement policy completely turned on its head. Although they didn’t have any speciic igures to hand, it seems likely brand new vehicles will start arriving in the very near future. “We’re looking very closely at every minute detail,” Taylor tells us, with reference to the total whole life running costs of used versus new.

“At present, the scales seem to be tipped in favour of new. The strategy would probably see us take one new Renault Premium every month for a full year, which would [potentially] be carried on as a permanent policy forever.” Part of the turnaround has come from the unknowns. “Take tyres as a good example: a used truck could need a set straight away, whereas a new vehicle with decent OE rubber could last 18 months or more without the need to change anything.” The changes will also see the TTX leet move towards a standardised 44 tonnes: “We don’t tend to go out heavy, but there’s always the issue of backloading. It’s very easy to lift the sixth axle up out of the way if you don’t need it, but it’s very dificult to produce one from a ive axle rig!”

Mixing it up

The company operates a mix of curtainsiders (60%) and box vans (remaining 40%), 80 of which belong to TTX and roughly 40 are hired in from Cartwright Rentals. “We’ve got an excellent working relationship with the boys from Altrincham too. We hire their trailers, they send us MOT and repair work.” In addition to vehicle acquisition, Taylor says the entire team at TTX are constantly looking at where the company is positioned in the marketplace and how that impacts on the business as a whole. “With a leet of this size you’ve got to think commercially at each and every step of the way. You need to be as good as possible at each and every thing you do,” he advises. Cost reduction and synergy is obviously a key part of the process, which will extend down to the way new trucks are painted. From now on, new vehicles will feature a painted dark blue base, with the trademark lime green added as a wrap. “That process will save us considerable amounts of agro when it comes to asset disposal.” Taylor and the team have also been convinced (beyond all reasonable doubt) that staff training lies at the heart of a proicient and professional business. “We rely on both internal and external training, not just to cover health and safety issues, but also an overall reduction in fuel usage. To that end, the Driver CPC has been a good thing,” he agrees.

Taylor rounds off the interview with a casual peek into the future. If we come back in 10 years time, where will he be?

“For us, it’s become a numbers game, so I would say maybe double the leet size we have today. We want to be heavily service-led, promoting the company to the best of our ability. But whatever happens, I would never like to be in a position where I didn’t know the name of each and every person who works here,” he concludes.