road and workshop

Page 92

If you've noticed an error in this article please click here to report it so we can fix it.

by Handyman

Auto-electrics for the mechanic (75)

OVER THE past few years the word "transistor" has come into everyday use. To the general public it conjures up some form of portable radio but the uses of the transistor extend to many applications far removed from radio, among them being a much improved system of charging control.

The transistor is basically a form of semiconductor, made up of specially treated crystals of either silicon or germanium. Where this device is coupled into a suitable circuit it can in fact provide the same service as a thermionic valve. Because of its small size, strength and surprising reliability — and particularly the fact that there is no filament using current — it requires very little power indeed, and can operate as an electrical amplifier or switch. For these reasons transistors offer an ideal means of automatic control for dynamo field regulation, and can be applied to ignition systems.

Space saving

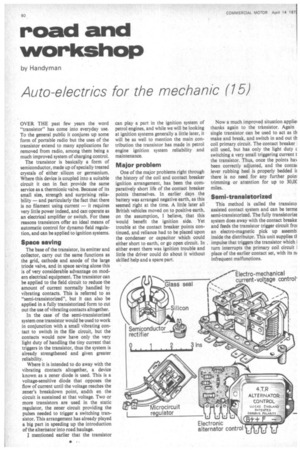

The base of the transistor, its emitter and collector, carry out the same functions as the grid, cathode and anode of the large triode valve, and in space saving alone this is of very considerable advantage on modern electrical equipment. The transistor can be applied to the field circuit to reduce the amount of current normally handled by vibrating contacts. This is referred to as "semi-transistorized", but it can also be applied in a fully transistorized form to cut out the use of vibrating contacts altogether.

In the case of the semi-transistorized system one transistor would be used to work in conjunction with a small vibrating contact to switch in the file circuit, but the contacts would now have only the very light duty of handling the tiny current that triggers in the transistor, thus the system is already strengthened and given greater reliability.

Where it is intended to do away with the vibrating contacts altogether, a device known as a zener diode is used. This is a voltage-sensitive diode that opposes the flow of current until the voltage reaches the zener's breakdown point, andth en the circuit is sustained at that voltage. Two or more transistors are used in the static regulator, the zener circuit providing the pulses needed to trigger a switching transistor. This arrangement has already played a big part in speeding up the introduction of the alternator into road haulage.

I mentioned earlier that the transistor can play a part in the ignition system of petrol engines, and while we will be looking at ignition systems generally a little later, it will be as well to mention the main contribution the transistor has made in petrol engine ignition system reliability and maintenance.

Major problem

One of the major problems right through the history of the coil and contact breaker ignition arrangement, has been the comparatively short life of the contact breaker points themselves. In earlier days the battery was arranged negative earth, as this seemed right at the time. A little later all British vehicles moved on to positive earth, on the assumption, I believe, that this would benefit the ignition side. Yet trouble at the contact breaker points continued, and reliance had to be placed upon the condenser or capacitor which could either short to earth, or go open circuit. In either event there was ignition trouble and little the driver could do about it without skilled help and a spare part.

Now a much improved situation appliei thanks again to the transistor. Again single transistor can be used to act as th make and break, and switch in and out th coil primary circuit. The contact breaker still used, but has only the light duty c switching a very small triggering current t the transistor. Thus, once the points hav been correctly adjusted, and the contat lever rubbing heel is properly bedded it there is no need for any further poini trimming or attention for up to 30,0C miles.

Semi-transistorized

This method is called the transisto assisted contact system and can be terme semi-transistorized. The fully transistorize system does away with the contact breake and feeds the transistor trigger circuit froi an electro-magnetic pick up assemb, inside the distributor. This unit supplies a impulse that triggers the transistor which i turn interrupts the primary coil circuit i place of the earlier contact set, with its nt infrequent malfunctions.