Accuracy in cylinder and Crankshaft Grinding

Page 60

If you've noticed an error in this article please click here to report it so we can fix it.

i1-UCH of the beat work done in con.1.11_nection with the maintenance and repair of commercial vehicles is carried out by really practical men, often in small but well-equipped workshops, controlling staffs of skilled workers who have been specializing for years, and who can be trusted individually to put their best efforts into their tasks.

Such a business is that of Mr. S. Harris, whose works have been situated for over 20 years at the same address3, 9 and 10, Thornton Place, Marylehone, London, W.1 (telephone, Vv'elbeck 8163). So successful ha e he been in dealing with worn cylinders, crankshafts, etc., that some of the most difficult jobs are entrusted to him. Amongst regular customers are Woolwich Arsenal, the British Petroleum Co., Ltd., Keith and Boyle, Ltd. (proprietors of the Orange coaches), United Service Transport Co., Ltd., and Mann Egerton and Co., Ltd., whilst some of the Lon

c38

don service depots of well-known makers of commercial vehicles are sending their work to Thornton Place.

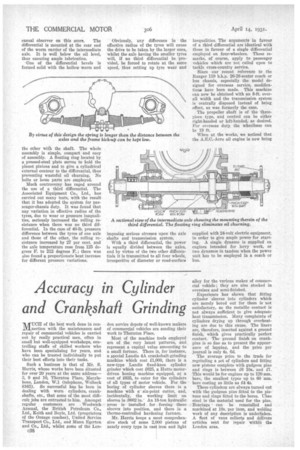

Most of the machine tools employed are of the very latest patterns, and represent a capital value amounting to a small fortune. There is, for instance, a epecial Landis 4A crankshaft-grinding machine which cast 11,000, there is a new-type Landis fixed-knee cylinder grinder which cost 1625, a Hutto motordriven honing machine equipped, at a cost of £635, to cater for the cylinders of all types of motor vehicle. For the boring of cylinder sleeves there is a machine with a six-point cutter, and, incidentally, the working limit on sleeves is .0002 in. An 18-ton hydraulic press is installed for forcing these sleeves into position, and there is a thernio-controlled hardening furnace.

Mr. Harris keeps a most comprehensive stock of some 2,000 pistons of nearly every type in cast iron and light alloy for the various makes of commercial vehicle ; they are also stocked in oversizes and semi-finished.

Experience has shown that fitting cylinder sleeves into cylinders which are merely bored out for them is not satisfactory, as the metallic contact is not always sufficient to give adequate heat transmission. Many complaints of cylinders drying up through overheating are due to this cause. The liners are, therefore, inserted against a ground finish, which gives practically perfect contact. The ground finish on crankpins is so fine as to present the appearance of lapping, and the price per journal is only 4s. 6d.

The average price to the trade for regrinding a eet of cylinders and fitting new pistons complete with gudgeon pins and rings is between /6 10s. and /7. This would be for engines up to 120 mm. bore, the smallest types up to 60 BrI.U. bore costing as little as £4 4s.

These cylinders are always turned out with the gudgeon pins fitted to the pistons and rings fitted to the bores. tbas steel is the material used for the pins. Bearings can be remetalled and machined at 10s. per item, and welding work of any description is undertaken. A fleet of vans collects and delivers articles sent for repair within the London area.