Technical Pointers on

Page 70

Page 71

If you've noticed an error in this article please click here to report it so we can fix it.

ROOF CONSTRUCTION

AN elliptically shaped coach roof is, as a rule, equipped with air extractors, and the rear portion is usually set apart for luggage. In order to form a bearing for the ventilator a piece of wood wider than the circumference of the ventilator, is cut out to the required size and fastened between two hoopsticks so that it is flush with the top of them.

At the place where the luggage is carried the roof framework is placed closer together than in front, or the hoopsticks are stouter and plated for their full length..

Although there are fewer joints in a plywood roof than in a boarded one, each pattern is covered with a stout fabric. Before this is put on the roof is given a heavy coat of white lead; linseed oil, japan and goldsize. The fabric is cut with a margin all around, so that it may be stretched tightly before the paint is dry, some of which it absorbs.

The roof is then given another coat of lead colour, and, when dry, further coats of colour, also fillings, are given according to the quality of .finish: desired., .. , e48

The tacks around the edges should be of copper, so as to prevent rusting, and they are hidden by the water guttering. This should be of large section, not only effectively to entrap the water running from a

large roof, but also to give it a bold finish.

The wood hoopsticks form a convenient foundation for securing inside roof panels. The joints of the panels are made at the hoopstick position and are hidden with mouldings. The whole may be painted white, preferably with a fiat finish to reduce reflections, or covered with an embossed paper. Openings are made for the reception of roof ventilators.

The hoopstick may be plated for its full length, or a compromise effected by splicing it at the ends. The hoopstick may also be a metal channel with side flanges and bottom slots. The channel is filled with wood, for which purpose timber otherwise wasted may be employed. The flanges are used to form a bearing for the top panel, which is secured to the wood filling. The slots in the base of the channel are used for the attachment of the lower panel, The luggage space on the roof has wearing slats, which protect the head fabric and panelling. It may be designed as a separate Unit, in order that the number of fixing points may be reduced to a minimum.

A high roof rail protects the baggage, but, at the same time, the luggage has to be lifted over it. To save time one or more sections of the rail may be hinged. It is suggested that the sides or ends of the enclosure be made up as gates. These could be hinged to stanchions and

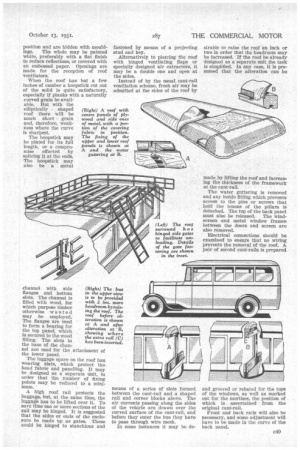

(Right) The bus in the upper view is to be provided with 2 ins. more headroom by raising the roof. The roof before alteration is shown at A and after alteration at ' B, showing where the extra rail (C) has been inserted.

fastened by means of a projecting stud and key.

Alternatively to piercing the roof with hinged ventilating flaps or specially designed air extractors, it may be a double one and open at the sides.

Instead of by the usual cant-rail ventilation scheme, fresh air may be admitted at the sides of the roof by means of a series of slots formed between the cant-rail and a shaped rail and corner blocks above. The air currents passing along the sides of the vehicle are drawn over the curved surface of the cant-rail, and before they enter the bus they have to pass through wire mesh.

In some instances it may be de sirable to raise the roof an inch or two in order that the headroom may be increased. If the roof be already designed as a separate unit the task is simplified. In any case, it is presumed that the alteration can be

made by lifting the roof and increasing the thickness of the framework at the cant-rail.

The water guttering is removed and any inside fitting which prevents access to the pins or screws that hold the tenons of the pillars is detached. The top of the back panel must also be released. The windscreen and metal window frames between the doors and screen are also removed.

Electrical connections should be examined to ensure that no wiring prevents the removal of the roof. A pair of second cant-rails is prepared

and grooved or rebated for the tops of the windows, as well as marked out for the mortises, the position of which is ascertained from the original cant-rail.

Front and back rails will also be necessary, and some adjustment will have to be made in the curve of the back panel.