Promising Epicyclic Gearbox

Page 93

If you've noticed an error in this article please click here to report it so we can fix it.

with novel hydraulic control

A New Transmission which Enables a Vehicle to be Controlled by Only Two Pedals and Affords a Very Easy Gear Change

WE have recently had the opportunity of testing, on the road, a new transmission, produced by Propello Inventions, Ltd., which embodies many interesting features. Although no new principle is involved in its construction, the performance is such as to command respect.

The transmission which we tried was fitted to a 10 h.p. car, but is of a form which would be quite suitable for light commercial vehicles. It is also being developed in larger, sizes and the main featureg have been evolved and tested over a period of several years. One of The experimental gearboxes has 50,000 miles on the road and another, of a slightly different type, now has 40,000 miles to its credit.

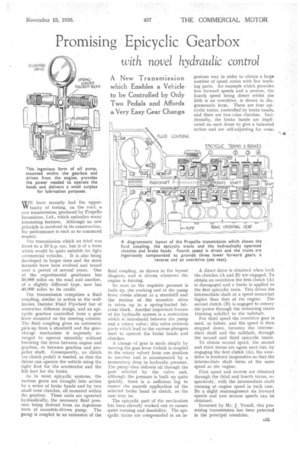

The transmission comprises a fluid coupling, similar in action to the wellknown Daimler Fluid Flywheel but of somewhat different design, and an epicyclic gearbox controlled from a gear lever mounted on the steering column. The fluid coupling gives an automatic pick-up from a standstill and the gearchange mechanism is. expressly arranged to operate smoothly without breaking the drive between engine and gearbox, or between gearbox and propellet shaft. Consequently, no clutch (or clutch pedal) is needed, so that' the driver can operate the vehicle using the right foot for the accelerator and the left foot for the brake,

As in most epicyclic' Systems, the various gears are brought into action by a series of brake bands and by two small cone clutches, all mounted within the gearbox. These units are operated hydraulically, the necessary fluid, pressure being derived from an ingenious form of eccentric-driven pump. The pump is coupled to an extension of the

fluid coupling, as shown in the layout diagram, and is driven whenever the engine is turning.

So soon as the requisite pressure is built up, the working end of the pump 'lever comes almost to a standstill and the motion of the eccentric drive is taken up in a spring-loaded fulcrum block. Another important feature of the hydraulic system is a restriction which is introduced between the pump and a rotary valve ; this valve controls ports which lead to the various plungers used to operate the brake bands and clutches.

A change of gear is made simply by moving the gear lever (which is coupled to the rotary valve) from one position to another and is accompanied by a momentary drop in hydraulic pressure. The pump then deliver§ oil through the port selected by the valve and, although the pressure is built up quite quickly, there is a sufficient lag, to ensure the smooth application of the selected brake band or clutch, as the case may oe.

The epicyclic part of the mechanism has been cleverly worked out to ensure quiet running and durability. The epicyclic trains are compounded in an in genious way in order to obtain a large number of speed ratios with few working parts. An example which provides five forward speeds and a reverse, the fourth speed being direct whilst the fifth is an overdrive, is shown in diagrammatic form, There are four epicyclic trains, controlled by brake bands, and there are two cdne clutches. Incidentally, the brake bands are duplicated on each drum to give a balanced action and are self-adjusting for wear.

A direct drive is obtained when both the clutches (A and B) are engaged. To obtain an overdrive the first clutch (A) is disengaged and a brake is applied to the first epicyclic train. This drives the intermediate shaft at a speed somewhat higher than that of the engine. • The second clutch (B) is engaged to convey the power through the remaining trains (turning solidly) to the-tailshaft.

• For third speed the overdrive gear is used, as before, and the speed is then stepped down, between the intermediate shaft and the tailshaft, through the second and third epicyclic trains.

TO obtain second speed, the second and third trains are again used but, by engaging the first clutch (A), the overdrive is rendered inoperative so that the intermediate shaft. turns at the same speed as the engine.

First speed and reverse are obtained through the third and fourth trains, respectively, with the intermediate shaft running at engine speed in each case. By a slight rearrangement six forward speeds and two reverse speeds can be obtained.

Invented by Mr, J. Yoxail, this promising transmission has been patented in the principal countries.