New Constructional Principle in

Page 79

If you've noticed an error in this article please click here to report it so we can fix it.

Latest Multiwheeler 15-ton Trailer

Echelon Arrangement of Rear Wheels Permits Lighter Construction and has Other Advantages .

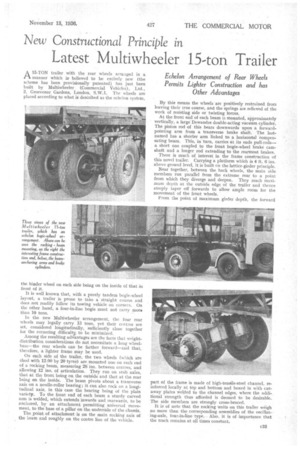

A15-TON trailer with the rear wheels arranged in a manner which is believed to be entirely new (the scheme has been provisionally patented) has just been built by Multiwheeler (Commercial Vehicles), Ltd., 3, Grosvenor Gardens, London, S.W.1. The wheels are placed according to what is desoribed as the echelon system,

the hinder wheel on each side being on the inside of that in front of it.

It is well known that, with a purely tandem bogie-wheel layout, a trailer is prone to take a straight course and does not readily follow its towing vehicle on corners. On the other hand, a four-in-line bogie must not carry more than 10 tons.

In the new Multiwheeler arrangement, the four rear wheels may legally carry 13 tons, yet their centres are set, considered longitudinally, sufficiently close together for the cornering difficult); to be minimized. Among the resulting advantages are the facts that weightdistribution considerations do not necessitate a long wheelbase—the rear wheels can be farther forward—and that, therefore, a lighter frame may be used.

On each side of the trailer, the two wheels (which are shod with 12.00 by 20 tyres) are mounted one on each end of a rocking beam, measuring 28 ins, between centres, and allowing 12 ins, of articulation. They run on stub axles, that at the front being on the outside and that at the rear being on the inside. The beam pivots about a transverse axis on a needle-roller bearing ; it can also rock on a longitudinal axis, in this case the bearing being of the plain variety. To the front end of each beam a sturdy curved arm is welded, which extends inwards and searwards, to be anchored, by an attachment permitting universal movement, to the base of a pillar on the underside of the chassis.

The ,point of attachment is .on the main rocking axis of the beam and roughly on the centre line of the vehicle.

By this means the wheels are positively restrained from leaving their true course, and the springs are relieved of the work of resisting side or twisting forces.

At the front end of each beam i3 mounted, approximately vertically, a large Dewandre double-acting vacuum cylinder. The piston rod of this bears downwards upon a forwardpointing arm from a transverse brake shaft. The lastnamed has a shorter arrn linked to a horizontal compensating beam. This, in turn, carries at its ends pull-rods—. a short one coupled to the front bogie-wheel brake camshaft and a longer rod extending to the rearinost brakes.

There is much of interest in the frame construction of this novel trailer. Carrying a platform which is 4 ft. 6 ins. above ground level, it is built en the lattice-girder principle.

Near together, between the hack wheels, the main side members run parallel from the extreme rear to a point from which they diverge and deepen. They reach maximum depth at the outside edge of the trailer and thence steeply taper off forwards to allow ample room for the movement of the front wheels..

From the paint of maximum girder depth, the forward part of the frame is made of high-tensile-steel channel, reinforced locally at top and bottom and boxed in with cutaway plates welded to the channel edges, where the additional strength thus afforded is deemed to be desirable. The side members are strongly cross-braced. It is of note that the rocking units on this trailer weigh no more than the corresponding assemblies of the oscilla,t• ing-axle, four-in-line type. . Also, it is of importance that the track remains at all times constant.