HINTS ON MAINTENANCE.

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

519.—Improving the Back Axle of the 30-cwt. Overland..

On two occasions the screwed Ting holding the crown wheel up to the bevel in the back axle of a 1917 30-cwt. Overland was forced back into its

housing, stripping the threads on the ring and so. rendering it useless.

The cause was believed to be the stresses due to braking, and to obviate the trouble a new method of fixing the ring was decided upon.

When the new ring was obtained, the retaining clip was scrapped, and two further holes were drilled and tapped to INin. in the housing at equidistant points . from that for the clip. Into these holes were inserted hardened setscrews provided with locknuts. The ring was then countersunk at three places to receive the ends of the setscrews, these countersinks being carefully positioned so that they came in line with the setscrews. The ring was then fitted in and adjusted to the correct position, and-the setscrews tightened and locked by the nuts.

520.—Rejuvenating an Old Edison Battery.

We have on several occasions been asked to advise our readers as to the procedure to be followed when dealing with old Edison batteries. The following details, which we have obtained through the courtesy of Edison Accumulatorst Ltd., will be of interest. The correct procedure when taking the old battery in hand is to discharge it through a resistance down to zero, and then to short-circuit it and leave it in that condition for at least six hours. It should then be washed out with distilled water, or preferably with a weak solution of the standard electrolyte —which is caustic potash. The cells should then be filled with the electrolyte, which consists of a special solution composed mainly of pure caustic potash. The battery must now be put on charge at the normal rate for twice the normal period.

1342

If the treatment does not appear to bring the bat, tory up to the proper condition, the discharge and recharge cycle may be repeated, after which, if the readings are still not normal, it may be assumed that the capacity has suffered from some cause or other. It must be noted that when 'a battery is taken out of service and stored for a considerable period, it should• be fully discharged. The cells should not, however., be emptied. The level of the electrolyte must be maintained by adding distilled water, say, every two months, to make up for evaporation. The plates should never be exposed, and the correct height of the solution above their tops is in.

With regard to the voltage, this reads about 1.85 per cell at the end .of a charge if the battery is in good condition. It will, however, soon settle down to 1.5 volt per cell.

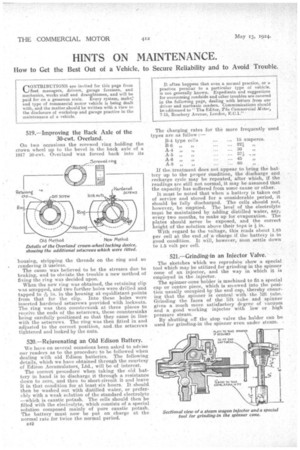

521.—Grinding-in an Injector Valve.

The sketches which we reproduce show a special tool which may be utilized for grinding-in the spinner cone of an injector, and the way in which it is employed in the injector. The spinner-cone holder is machined to fit a special cap or centre piece which is screwed into the position usually occupied by the end cap, thereby ensuring that the spinner is central with the lift tube. Grinding the faces of the lift tube and spinner gives a much more satisfactory degree of vacuum and a good working injector with low or high pressure steam. By shutting off the stop valve the holder can be used for grinding-in the spinner even under steam.