4,000-gal. Si x-wheelei

Page 84

Page 85

Page 86

Page 87

If you've noticed an error in this article please click here to report it so we can fix it.

yes 11.6 m.p.g.

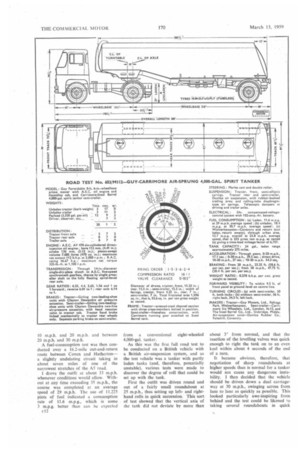

By John F. Moon, A.M.I.R.T.E. BECAUSE of the lower stresses set up by air suspension, much chassis and body weight can be saved in vehicles designed for it from the start. An excellent example is seen in the six-wheeled articulated tanker just tested exclusively by The Commercial Motor, which has a capacity of 4,000 gal. of petrol, a quantity hitherto transportable only

on four axles.

An appreciable saving in weight results in the outfit operating at 20 tons gross train weight, and allows the use of a smaller engine than is normally found in tankers of this capacity. Thus, good fuel economy can be obtained without noticeable loss of performance, and• on test 11.6 m.p.g. was recorded at an average speed of 29 m.p.h. with a load equivalent to 4,000 gal: of petrol.. The use of the lighter vehicle also spells economy in terms of lower initial cost and reduced tyre and brake maintenance.

The Guy Formidable motive unit was fitted with Dunlop trailing-arm air suspension. Similar suspension components were employed in the Catrimore running gear for the Steel Barrel 4,000-gal. mild-steel tank.

Rolling-lobe Springs

Pneuride rolling-lobe diaphragm air springs are incorporated in the semitrailer and tractor suspension layouts. The tractor springs are of 10-in. diameter, whilst those on the semitrailer have a diameter of 12 in. Each spring has a Dunlop levelling valve. Woodhead Monroe 2-in, telescopic shock absorbers provide the suspension damping of the semi-trailer, and Armstrong AT 11 dampers are used on the tractor driving axle.

Air suspension has enabled about 1+ tons to be saved in the weight, compared with a steel-sprung tandemaxle outfit of the same capacity. This has been achieved by the use of thinner tank-shell material and the abolition of full-length longitudinal under ribs.

The tractor employed for the test was an 8-ft. 6-in.-wheelbase prototype fitted with a Homalloy light-alloy cab. As originally exhibited at the Commercial Motor Show last year, this tractor had a Meadows 6DC 500 oil engine, but it has been replaced by an A.E.C. AV 470 six-cylindered oil engine in the interests of weight saving.

It had been intended that the test Eio should be conducted with the second Formidable tractor to be supplied to Mobil Oil Co., Ltd., who kindly arranged for the loan of the outfit, but this was not ready in time. It is essentially similtr to the prototype used for the test, except that a standard Guy part-plastics cab is employed and the complete tractor is some 2 cwt, lighter than the prototype.

The tractor is rated for a gross train weight of 20 tons and is available with a choice of power units, including A.E.C., Leyland and Meadows. The A.E.C. 112 b.h.p. engine is unitmounted with an A.E.C. five-speed synchromesh gearbox, driving through a single propeller shaft to a spiralbevel rear axle. The tractor has Girl ing two-leading-shoe wedgeoperated brake units, actuated through a Clayton Dewandre air-pressure system. The braking equipment on the driving axle is similar to that of the semi-trailer axle.

Both the tractor and the semi-trailer have Dunlop Highway tubeless tyres on 6.75-22.5-in.. disc wheels. The use of these tyres also saves weight— I60 lb. in the case of the semi-trailer as against equivalent running gear on conventional 9.00-20-in. tyres. The same size of tyre is fitted to all wheels of the outfit and no spare is carried— a further weight saving, In the interests of safety, the vehicle was not supplied for test carrying its normal payload of petrol. Instead, the tank had been loaded with lowsulphur gas oil, equivalent in weight to 4,000 gal. of motor spirit when the difference between the weights of the prototype and production tractor is taken into account. The gross train weight without driver was 19 tons 18 cwt., the tractor driving axle and the semi-trailer axle being equally loaded.

First-class Braking

Braking tests were conducted first and exceptionally good retardation figures were obtained from both 20 m.p.h. and 30 m.p.h. Retardation was deceptively smooth, with no trace of jack-knifing or instability and with little delay in the air-pressure system. The figures obtained would have been good for some vehicles running at half this weight, and reflect great credit on the overall braking design of the outfit and its favourable inter-axle weight distribution.

After the foot-brake tests, a series of hand-brake applications was made from 20 m.p.h. The tractor hand brake, which operates on the driving axle only, produced a retardation figure of 15.5 per cent. as shown by the Tapley meter. The braking system includes a hand reaction valve on the steering column for separate control of the semi-trailer brakes, and when applied from 20 m.p.h. an average Tapley-meter figure of 27.5 per cent. was recorded.

A third set of figures was then taken, employing both hand brakes, applying the semi-trailer brake first and pulling the tractor brake on hard. In this way an average figure of 37.5 per cent. was obtained from 20 m.p.h. Thus it was shown that combined use of the two hand-brake controls could give a retardation rate greater than 50 per cent. of that produced by the foot brake alone.

The same stretch of road was used for the acceleration test s. These were also highly satisfactory, particu larly from a standstill to 30 m.p.h., Using second, third, fourth and fifth gears. Much time was saved during this test by the efficiency of the gearbox synchromesh.

Despite its relatively small size, the A.E.C. engine has a good torque output, which yielded satisfactory figures in direct drive between 10 m.p.h. and 30 m.p.h. No transmission roughness was noticed at any . point between these two speeds, and the acceleration was constant between 10 m.p.h. and 20 m.p.h. and between 20 m.p.h. and 30 m.p.h.

A fuel-consumption test was then conducted over a 16.2-mile out-and-return route between Coven and Hathertona slightly undulating circuit taking in about seven miles of one of the narrowest stretches of the AS road.

I drove the outfit at about 33 m.p.h. whenever conditions would allow. Without at any time exceeding 35 m.p.h., the course was completed at an average speed of 29 m.p.h. The use of 11.225 pints of fuel indicated a consumption rate of 11.6 m.p.g., which is some 3 m.p.g. better than can be expected from a conventional eight-wheeled 4,000-gal. tanker.

As this was the first full road test to be conducted on a British vehicle with a British air-suspension system, and as the test vehicle was a tanker with partly laden tanks (and, therefore, potentially unstable), various tests were made to discover the degree of roll that could be set up with the tank.

First the outfit was driven round and out of a fairly small roundabout at 25 m.p.h., thus setting up leftand righthand rolls in quick succession. This sort of test showed that the vertical axis of the tank did not deviate by more than about 3° from normal, and that the reaction of the levelling valves was quick enough to right the tank on to an even keel within about 4 seconds of the end of a turn.

It became obvious, therefore, that negotiation of sharp roundabouts at higher speeds than is normal for a tanker would not cause any dangerous instability. I then decided that the vehicle should be driven down a dual carriageway at 30 m.p.h., swinging across from lane to lane as quickly as possible. This looked particularly awe-inspiring from behind and the test could be likened to taking several roundabouts in quick ession, which at 30 m.p.h. would be nst impossible.

3ntrary to appearances, the driver lied that the vehicle was in no way able, and as soon as he corrected steering wheel to straighten out the It, the semi-trailer responded after a lurch, A Tapley meter had been ed at the back of the tank to record werse decelerations, and after this the meter's maximum reading was )er cent., showing that deceleration ng the roll had at no point reached then drove the outfit to Bridgnorth, 'e hill-climbing and brake-fade tests : made on Hermitage Hill. This ient is f mile long, with an average rity of 1 in 12. Near the top there steep section of 1 in 8, se climb was made at an ambient mrature of 52° F. and took minutes, the radiator coolant ternture rising from 170° F. to 182° F.— enough limits for normal use in this itry.

Steady Pulling

le lowest gear used during this climb second, which was engaged for imutes 24 seconds. When on the >est section of the hill the speed ped down to 3 m.p.h., but the engine pulling steadily and I was agreeably rised at not having to engage bottom

le vehicle was turned round. at the of the hill and then coasted down gradient in neutral, using the foot e to restrict the speed to 20 m.p.h. he bottom of the hill the foot brake applied from 20 m.p.h. and a cy-meter figure of 55 per cent. was -ded, showing that fade had unted for a drop of only 15 per , which is commendably small for a :le of this weight.

!turning to the steepest section of hill, the outfit was stopped and it found that the tractor hand brake t. would not "hold," but with the -trailer hand brake applied, the :le remained stationary. Attempts to in bottom gear resulted in proced clutch-slip, but the vehicle tually pulled away. and the test was tted twice to make sure that the result was not a fluke.

Clutch Wear

was obvious, however, that the le was working at the top limit in awer and the clutch-pedal clearance disappeared by the time the tests been finished. Slight exhaust smokvas noticed during this test and the :ding non-stop climb.

r the unladen tests, the outfit was n from the Guy works to the Mobil plant at Coventry, where arrange s had been made to discharge the The route chosen was through erhampton and Walsall and along astern outskirts of Birmingham, and 6 miles took 1 hour 40 minutes. ving discharged the load, the return ley from Coventry over this route rade in 1 hour 20 minutes, and the fuel used for the round trip was 5 gal. 5.5 pt., giving an overall consumption rate of 12.7 m.p.g. at an overall average speed of 23.8 m.p.h.

While at the depot, the tractor and semi-trailer frame heights were measured before and after unloading. The tractor frame height was reduced by f in. with the load off, whilst the height at the semi-trailer frame increased by If in. A Tapley meter on the tank indicated a change in tank level of less than 1°, the rear of the tank being slightly higher than when the load was aboard.

With the tank empty, the 16.2-mile fuel-consumption test was repeated. A figure of 18.4 m.p.g. at an average speed of 30.7 m.p.h. was obtained, the maximum speed being no greater than that during the laden run.

Thus, from the three sets of fuel figures obtained it can be assumed that the 12.7 mpg. rate yielded between Wolverhampton and Coventry is the figure that can be expected when running through urban and industrial areas. On trunk-road deliveries under less arduous traffic conditions, an overall figure of some 15 m.p.g. may be expected, which is a vast improvement on the fuel return available with an eight-wheeled tanker of the same volume.

The semi-trailer was then disconnected completely and the tractor driven over some rough ground to study the effect of the air suspension under such conditions. Motion at the rear was found to be smooth, with nothing like the normal amount of pitching experienced with a short-wheelbase forward-control tractor unit. The steel semi-elliptic frobt springs gave a decidedly harsher ride, accentuated by the absence of dampers at the axle.

Even under exaggerated cornering conditions, the tank, whether laden or unladen, was perfectly stable, whilst the outfit rode smoothly over varying road surfaces.

Fast cornering on roundabouts showed that the tractor unit tended to lean more than the semi-trailer. The probable reason is that the semi-trailer axle is rigidly bolted to its trailing arms, whereas the tractor axle is rubber mounted to the off-side arm to allow a limited amount of roll without overstressing the axle case or the trailing arms, the mounting at the near side of the axle being rigid for torque-reaction purposes.

The behaviour of one of the levelling valves on the tractor became a little erratic half-way through the test, with the result that when unloading the tank the bellows pressure was not reduced. This defect cured itself later in the day. The air-suspension units seem to be satisfactory, although the application is virtually experimental, but-further design work on the levelling valves and delayperiod settings needs to be done.

Smooth riding is maintained irrespective of whether a load is being carried or not, with obvious benefits. The level of the tank remains almost constant, irrespective of the amount of load or its distribution; the overall height of the complete vehicle should not vary more than an inch. Moreover. coupling and uncoupling are simplified because there is no need to allow for an increase in tractor fifth-wheel height when drawing away from beneath the semi-trailer.

As might be expected in view of the low frontaxle loading, the steering was pleasantly light without being vague. and despite its small size the engine pulls well, the matched spread of gearbox ratios enhancing acceleration and making it possible to keep up high average trip speed.

Brake Sensitivity

The brakes are fully proportional to pedal travel and a conventional brake pedal, instead of a treadle type, is employed, thus retaining full sensitivity in the system. The Homalloy cab gave good forward visibility, whilst the low engine cowl tended to create an added air of spaciousness.

This test highlights the advantages that can be derived from intelligent use of air suspension, particularly with articulated units. It shows that either a smaller tractor (with smaller engine) can be used for hauling 4,000-gal, payloads because of the vehicle weight saved, or much more than 4,000 gal. could be carried by an eight-wheeled articulated outfit.

Weight saving in the tractor alone, for instance, is just over 1 cwt., principally because the steel rear springs of the standard vehicle together weigh over 5 cwt. Less fuel is used for the same payload, the first cost and annual tax are lower, and chassis, body and spring life are longer.