Passing Comments

Page 32

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

Easier Automation With Standard Units

THE advent of automation has called for the construction I of special machines of all kinds. The building of these has overloaded the machine-tool industry, thus retarding the new technique of production.

One result of this " bottle-neck " has been the division of machines into components which can be adapted to various types for different processes. Such units are driving heads, vertical and angular columns, branch beds and pneumatic, hydraulic and electrical components. These are made up and stored, so that the call for another.special machine or equipment is largely a matter of drawing suitable standard components from stores and erecting the machine to the specification issUed by the drawing office.

Liquid Petroleum Gas as Fuel

pORK-LIFT trucks operating on liquid petroleum gas,

a number of which was shown at the Mechanical Handling Exhibition, represent a new use of an old principle that may have increasing importance in this country. The gas is a product of the crackitig process and the total amount produced in relation to other derivatives depends largely upon the policy of the oil companies.

In Germany, bottled gas is being extensively employed by combine-harvester operators, and a member of the staff of this journal who recently visited the Massey-HarrisFerguson combine factory in Eschwege, a German town near the Soviet border, learnt that the gas-driven machines are considered to be more economical than equivalent petrolor oil-engined models if the annual operating period A30 is between 60-260 hours. For fewer than 60 hours the petrol engine offers the lowest running costs, but above 260 hours the oil engine has a slight advantage.

This evaluation does not take into consideration, however, the improved low-speed torque of the spark-ignition engine running on gas, or the longer period the unit can operate without an overhaul, by virtue of the reduced oil contamination.

Bottled gas is marketed by a number of suppliers and has an S.A.E. octane rating of up to 115, compared with the average of 86 for premium fuel. • Further information regarding the economic and operational advantages of liquefied gas applied to various types of power unit will be awaited with interest. Its applicationto small road vehicles is a possibility of obvious interest to many operators. This gas is far more efficient than producer gas.

Where Responsibility Pays

pSYCHOLOGY, when properly utilized, can have an important and satisfactory influence upon production and even on the treatment of the machine-tool and other equipment by the workers employed.

A good example is to be found in the works of British Timken, Ltd., at Duston. There are to be found hundreds of valuable machine tools, some costing many thousands of pounds and each of them bears a notice as to how much it cost. This is considered to induce more care in its treatment, for it gives the operator a feeling of pride at his responsibility and the trust placed in him. It certainly seems that the scheme is giving satisfaction on both sides.

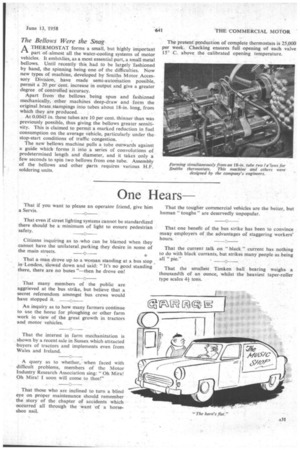

The Bellows Were the Snag

A THERMOSTAT forms a small, but highly important " part of almost all the water-cooling systems of motor vehicles. It embodies, as a most essential part, a small metal bellows. Until recently this had to be largely 'fashioned by hand, the spinning being one of the difficulties. Now new types of machine, developed by Smiths Motor Accessory Division, have made semi-automation possible, permit a 20 per cent. increase in output and give a greater degree of controlled accuracy.

Apart from the bellows being spun and fashioned mechanically, other machines deep-draw and form the original ,brass stampings into tubes about 18-in, long, from which they are produced.

At 0.0045 in. these tubes are 10 per cent. thinner than was previously possible, thus giving the bellows greater sensitivity. This is claimed to permit a marked reduction in fuel consumption on the average vehicle, particularly under thestop-start conditions of traffic congestion.

The new bellows machine pulls a tube outwards against a guide which forms it into a series of convolutions of predetermined length and diameter, and it takes only a few seconds to spin two bellows from one tube. Assembly of the bellows and other parts requires various H.F. soldering units.