. MUD . .WATER... DUST :( ATERS II 2 By Laurence J. Cotton, M.I.R.T.E.

Page 42

Page 43

Page 44

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

jpULLING a loaded 15-ton trailer across Long Valley was child's play to the Scammell Explorer ,--. ,until it encountered a crater .partly filled with a 31iripery morass and covered with a crust of hard soil. The ':-•ontents of this crater—churnings inherited from yes t f Tank-trick pounding—would have caused most

Mk"' vehicles to ,bog down, and the Scammell, 'with its trailer of 31 tons gross train weight, was a victim.

It was a difficult situation from which to extricate the outfit-12 Wheels sunk deep into the mud; four axles bellied on the ground and a mass of soil built up like a plaster cast to the front and rear. Laying out the winch rope for self-recovery was tricky, because at practically every step we broke through the crust and

. sank into the ooze up to knee level. Rescuing rubber boots was a two-handed effort.

We were saved the labour of putting down an anchor by the timely arrival of a heavy Tank, and the winch rope was hastily anchored on the bull. It was with relief that I saw the rope tighten, the tractor move slowly forward, and emerge from the crater. My enthusiasm was short-lived, because the trailer, climbing out at an angle of 20 degrees, dug its wheels deep into the soil and caused the winch governor to operate, thereby stalling the engine. This meant that the pull on the winch rope was more than 10 tons, thus giving some indication of the tractive resistance set up.

Repeat attempts met the same fate, so there was t10 alternative but to uncouple and rescue the trailer as an independent unit. This was accomplished with relative ease. Credit must be given to the sturdiness of the Scammell and its excellent braking system, which held the tractor without need for anchoring. :

This was one of the .highlights of 250 miles of road, crosS-cotintry'and wading trials of the Scammell petrol-"eugined_ttactor with Tasker timber carriage. . Because of the intricate transmission and wincli-diive equipment built into -a six-wheeled' all-wheel-driveModel,. it is ng impossible to condense its full specification into a few paragraphs:. The Scammell-Meadows engine employed is based on the compression-ignition unit, but having approximately 55 lb.-ft. more torque and increased power. (175 net b,h.p.) at the governed speed of 2,400 r.p.m.

It has twin Solex horizontal non-spill carburetters, petrol being supplied by a David single-diaphragm pump drawing its supply from a 70-gallon tank. A Vokes filter is employed between the pump and carburetters, and air for combustion is drawn from two oil-bath cleaners fitted externally on the bonnet. A vertical magneto is fitted and the winch-rope governor operates on the ignition system. Maximum engine speed is controlled by a centrifugal governor which takes effect on the throttle linkage.

Belt-driven components at the front of the engine include a Clayton Dewandre two-cylindered air-cooled compressor, with a capacity of 15 cubic, ft. of 'free air at 1,000 r.p.m., and a close-cowled six-bladed 24-in.diameter fan. A water jacket around the exhaust . manifold reduces under-bonnet temperature. •

The engine is designed to operate in climates ranging from —10 degrees F. to +125 degrees F., and the cooling and lubrication systems are arranged for Climb= ing gradients of up to 35 degrees in conjunction with a • . side slope of 15. degrees. The' sarnp has front arid rear wells with an additional pump to scavenge the . front chamber and transfer oil to the rear well:. Lubricant is passed through twin Tecakinit filters having a. capacity • of 1,640 gallons per hour and a -maximum working pressure of 150 lb: per sq. in. An air-cooled 'radiator at the front of the mainradiator cools the oil The engine is supported on a three-point mounting employing Metalastik units,:and.the. gearbox is ;carriedr-• separately in the frame and connected to the clutch a short shaft having Metalastik couplings. Constant mesh for all but the bottom and reverse ratios,. with engagement by sliding dog clutches, simplifies gear changing. There are six forward gears, top being an overdrive, giving a range of speed from 3* m.p.h. to 38i m.p.h. at governed engine revolutions. A transfer box with direct drive to the bogie and reduction gear to the front axle, is attached direct to the gearbox. The Explorer front-wheel drive includes a dog clutch for selective engagement, either when moving or stationary.

The transmission system in the front axle includes a double-reduction spiral-bevel and epicyclic train driving the wheels through a bevel differential and constantvelocity joints. At the front a single transverse spring, attached by a central pivot to the frame, permits one wheel to ride over a 2-ft. hump without stressing the main frame. The spring is located in the chassis by a triangulated structure with a perch. bar. The same amount of articulation is afforded to the bogie wheels.

Drive to the bogie is through a single worm assembly, which is connected by differential shafts to the side cases attached to the extremities of the axle. Pinions, mounted on the differential shafts, are connected through idlers, which mesh with gears attached to the wheel-drive shafts. These side cases are fully enclosed, each train having an independent oil supply. At the rear there is a separate spring on each side, secured at the front by shackle pins, and at the rear by cast-iron slippers.

Power steering is provided. An air-pressure cylinder attached to the frame operates the drop arm through a differential gear which takes effect on a reaction valve controlling air flow to the cylinder. There are separate reservoirs for the steering and braking air supply. The Clayton Dewandre brakes on the bogie are assisted by air pressure, but all other wheels on the tractor and trailer are braked by direct action of the pedal. A "hill-holder " lever at the head of the .steering tube is interconnected with the air-pressure system on the bogie.

Because of the degree of axle articulation envisaged in the tractor, the mechanical linkage of the bogie braking system is more complex than normal. The central operating lever is connected by short wire ropes linked in a horizontal plane to the cam levers which project through the inner sides of the gear cases.. No cross-country vehicle is complete without some means for self-recovery, and for pulling an accompanying trailer and its load out of difficulties. The Explorer has winch gear that can deal with direct loads from 10-15 tons, according to the amount of winch rope on the drum. At its base the drum is 20 ins, in diameter, and has 450 ft. of i-in. wire rope. Worm and spur-gear drive affords an overall reduction of 95 to 1. Pulleys and guide rollers are fitted to the chassis for front or rear winching. As I intended to make a full cross-country test with the Scanunell, it was necessary to obtain a trailer which would carry a heavy load and have the requisite ground clearance and axle articulation to negotiate ditches. I was fortunate in finding such a trailer in the Taskers 15-ton timber carriage. This has a square backbone fabricated from channel-section steel, which is supported in the rear carriage by phosphor-bronze bearings, allowing the bogie to twist round the pole when traversing rough country. At the front there is a simple axle supported by two wheels, whilst at the rear the four wheels are carried in tandem on beams pivoted at the centre of the main axle. The tractor wheels are arranged for 1 ft. rise or fall and the trailer wheels can move plus or minus 10 ins, without stressing the frame. The advantage of such articulation was apparent on Long Valley, where in negotiating some areas the wheels on one side were 1 ft. 8 ins, higher than those at the opposite end of the bearer, yet the load on the tyres was fully equalized. From towing eye to rear, the trailer measured 40i ft., and the wheelbase is adjustable from 14 ft. to 30 ft. between centres. . Becatise of the nature of the test course, consideratidn had to be given to the type of load. Logs ,might have been the easiest to find, but steel channel was preferred because of its lower centre of gravity. It took almost a day to load and secure the channels against movement. The wheelbase was adjusted to 21 ft, 9 ins. as ,a compromise between favourable tyre loading and manoeuvrability.

The trials were divided into four sections: (a) a test of the tractor solo, (b) hauling the trailer fully loaded, (e) operating with part of the load removed, and (d) crosscountry work.

Too Wide for Weighbridge

I collected the tractor at Watford and, after loading 5 tons of ballast into the temporary body, started for

the weighbridge. Here difficulties arose ,because the wheels overhung the sides of the table. With 14.0020-in. tyres, the vehicle was over 8 ft. 3 ins, wide, and we had to put blocks under the wheels before weighing. The weight of the blocks, in comparison with the 15 tons represented by the vehicle, was negligible.

Another 65•.gallons of petrol were added to fill the tank to.oVerflow point, in readiness for the solo run from Watford to collect the trailer at Andover. It was soon apparent that the Scammell was lively in acceleration and fast, because at 2,400 r.p.m. engine speed the road speed was 38 m.p.h. To save time we made a crosscountry journey through Langley and Datchet to F,nglefield Green, climbing the 1-in-9 gradient of Priest Hill at 17 m.p.h. with fifth gear in use. Acceleration and braking tests made en route indicated an acceleration rate of 1 m.p.h. per sec. to '30 m.p.h., and the excellent braking distance of 62 ft. from the same speed. The acceleration trials were made from rest in fourth gear.

When clear of Englefield Green, the speed was stepped up and the next 13 miles were covered in 30 mins before stopping for luncheon. After a short break the Scammell, too, appeared to be refreshed, and the next five miles were run at an average speed of 35 m.p.h.

Average of 30.5 m.p.h.

We stopped to refuel at a garage in Andover (65 miles from Watford), where 181 gallons of petrol were added, giving a fuel-consumption rate of 3 m.p.g. The average speed, including performance tests and delays in negotiating narrow streets and villages, worked out to 30.5 m.p.h. There is no doubt that, given. favourable road conditions, the Explorer can average 35 m.p.h. as a solo_ machine for indefinite periods.

The trailer, loaded to 21i tons gross, was collected at Taskers and the fuel tank replenished in readiness for a return consumption trial. The heavy load demanded great caution, and a different route had to be chosen to avoid .WhitchUrch and other towns which might present difficulties. More gear changes were required, and on one steep hill third gear was used for 4 mins. Even so, the radiator: water temperature remained within 95 degrees F. of the ambient reading, and in general running the temperature difference was 90 degrees F.

During acceleration tests the vehicle was again started in fourth gear, when it took 27.4 secs, to reach 20 m.p.h. and 101 secs. to 30 m.p.h. Considering the load and difficulties of making emergency stops on a drying road, the braking efficiency was exceptional. There was a tendency towards wheel-locking on the tractor which , had not: oCeurred when it was solo, but the trailer was free from sliding. The stopping distance from 20 m.p.h. was 47 ft. and from 30 m.p.h., 105 ft.

I took my turn at the wheel and noted especially the ease of gear changing with the constant-mesh box and the lightness of the steering, which with the air-pressure system, is approximately equal tO that of a 5-tonner. The addition of a diverter valve in the air system has smoothed the steering action,' and road shocks are damped. before reaching the wheel. A great advantage in a vehicle of the • Scammell type is the hill-holder brake, which is progressive in its action and a powerful retarder.

Scotts Hill, Rickmansworth, a 1-in-8 gradient, required rapid manipulation of the gear lever to change from top to the second ratio, which was required for a short time, but there was ample engine power and another gear available for steeper inclines. It required 25gallons of petrol to refill the tank at the end of 66.8 miles, corresponding to a consumption rate of 2.62 m.p.g. The average speed worked out to 22.3 m.p.h., which is fast haulage for a combination of 37 tons gross weight.

The Explorer, with pptrol engine, can cover at least half as much more ground a day than its predecessors. I was surprised that after this fast run with maximum load, the lubricant temperature in the worm pot registered only 172 degrees F.

Down to 31 Tons On the following day part of the load was removed to reduce the gross weight to 31 tons for cross-country Operation, and worn tyres were fitted to both the tractor and trailer. It would be unwise to risk 12 new tyres, costing approximately £100 apiece, on a cross-country test, and the pressures were a.djusted to 30 lb. per sq. in. for off-the-road operations.

Braking " and fuel tests were made between Watford and Farnborough, and with reduced load the fuel return worked out to 2.72 m.p.g. There was heavy earlymorning traffic and an obstruction on Egham Hill caused the use of third gear for over a mile. These delays made serious inroads into what might have been a fast run and the speed worked out to 22.3 m.p.h. When returning in the evening, the average speed was 28.5 m.p.h.

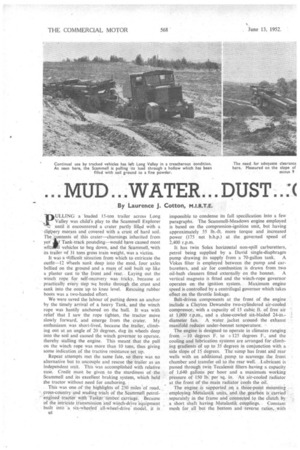

Long Valley was in a treacherous, condition. In parts the ground was as hard as rock; in other places a thin crust covered mud of paste consistency, and in patches the wheels sank deep into a powdery_ dust. Wheel articulation was put to full test, and I was watchful for any wheel which might leave the ground, but this did not happen. At some of the worst places I dismounted to guide the driver through a tricky spot, fearing that. because of its length, the trailer might be damaged.

Bogged Down In taking a short cut across the proving ground, the entire outfit settled down on its axles, but, as I have already recounted, the Scammell was able to extricate itself and load by self-recovery winching. Such occasions are common in cross-country work, and the winch gear provided on the tractor proved that it could pull out a heavy load without need for putting down pulleys for double, or more, reduction. The worn tyres on the tractor failed to bite into the mud, but had there been any vestige of bar tread left on the covers it is possible that the outfit would have kept moving and the work of recovery would have been done in an artificial setting.

I could not find a gradient which would stop the Scammell. It roared up the 1-in-2i slope in bottom gear, but winced when I made the second attempt in a higher ratio. With its trailer attached it was willing to climb the 1-in-4 concrete gradient on part-throttle,

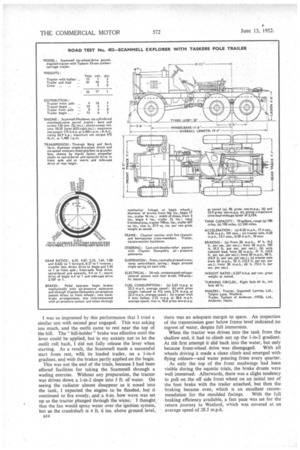

was so impressed by this performance that I tried a similar test with second gear engaged. This was asking too much, and the outfit came to rest near the top of the hill. The " hill-holder " brake was effective until the lever could be applied, but in my anxiety not to let the outfit roll back, I did not fully release the lever when starting. As a result, the Scamrnell made a successful start from rest, with its loaded trailer, on a 1-in-4 gradient, and with the brakes partly applied on the bogie.

This was not the end of the trials, because I had been offered facilities for taking the Scammell through a wading exercise. Without any preparation, the tractor was driven down a 1-in-2 slope into 3 ft. of water. On seeing the radiator almost disappear as it nosed into the tank, I expected the engine to be flooded, but it continued to fire evenly, and a 6-in. bow wave was set up as the tractor plunged through the water. I thought that the fan would spray water over the ignition system, but as the crankshaft is 4 ft. 6 ins, above ground level,

B14 there was an adequate margin to spare. An inspection of the transmission gear below frame level indicated no ingress of water, despite full immersion.

When the tractor was driven into the tank from the shallow end, it had to climb out up the 1-in-2 gradient. At th first attempt it slid back into the water, but only because front-wheel drive was disengaged. With all wheels driving it made a clean climb and emerged with flying colours—and water pouring from every quarter.

As only the top of the front mudwings had been visible during the aquatic trials, the brake drums were well immersed. Afterwards, there was a slight tendency. to pull on the off side front wheel on an initial test of the foot brake with the trailer attached, but then the braking became even, which is an excellent recom mendation for the moulded facings. With the full braking efficiency available, a fast pace was set for the return journey to Watford, which was covered at an average speed-of 28.5 m.p.h.