DIRECT IN

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

J

ECTIa

t\T

IN V CROSSLEY OIL ENGINE

IT was away back in 1931 that CrOsSley Motors, Ltd., Gorton, Manchester, put on the market the first bus to be powered by an oil engine. This operate.d on the direct-injection principle, but later the company changed over to indirect injection. Such was the type that was being produced before the war and it is interesting, therefore, to find that in the new Crossley unit, which has recently been announced, the concern has reverted to the directinjection system.

Whilst this is the first time that the engine has been described in detail, it has actually been in bus service for more than three years, and it is, therefore, a power unit which has been subjected to protracted tests.

• Compared with its predecessor, it is lightet in weight, but, structurally, it is, in many ways, superior. For instance, the crankshaft-bearing area has been increased, and the centre bearing is much larger, yet the overall length of the ertgi:_c has been reduced.

An interesting feature in the design is the use of two eels' of gears in the oil pump, so that, Virtually, there are two pumps. One, which works at high speed and pressure, is responsitle for supplying oil to only the crankshaft bearings, whilst the other, which feeds oil at low pressure. serves to supply lubricant to all the auxili'aries—camshaft, rocker shaft, timing chain, and so on.

Regarding the present combustion system, there is a toroidal "cup " formed in each piston crown, into which the fuel is injected direct. A feature of the " cups," or chambers, is that the surface is corrugated, and this, in conjunction with shrouded inlet valves, sets.up a threedirectional air swirl in the final phase of compression, just prior to the instant of injection.

With the Crossley type of combustion chamber, it is possible to employ a low injection pressure, the standard setting being from 100 to 120 atmospheres, which is law for a direct-injection engine. Advantages derived therefrom are a longer effective life of the nozzles, valves, fuel pump. and so on, owing to the considerable reduction in stresses and loads.

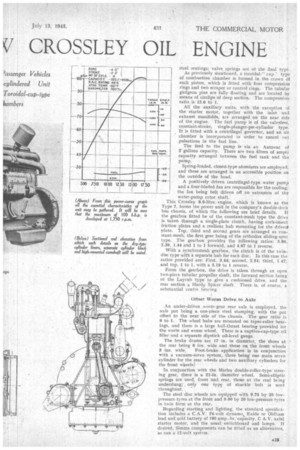

• Dealing now with the specification. The engine is of the six-cylinderecl, vertical, lout-stroke-cycle type, having a bore of 4 ins. (114.3 mar.) and a stroke of 5i ins (139.7 mm.). The capacity is thus 525 cubic ins., or 8,598 c.c.. It gives a maximum of 100 b.h.p. at 1,750 r.p.m., and delivers a maximum torque of 4,390 lb./ins. The Treasury rating is 48.6 h.p.

Separate Cylinder Block and Crankcase

The cylinders are cast en bloc and are separate from the crankcase, which is. in aluminium. Close-grained, airhardened castLiron. liners of the " dry " type are used in the cylinder bores. • A high-tensile steel crankshaft with vibration damper is , used and this is supported on seven bearings having leadbronze bottom halves and white-metal top halves. It is balanced both statically and dynamically, being machined all over, with surface-hard'ened journals; both the journals and the pins are ground and lap finished. In each ' crankpin there is a reservoir of generous capacity which serves as an oil retainer and to prevent partial starvation at this point on initially starting up.

In the case of the connecting rods, the top halves of the big-end bearings are cromet lined, with white metal for the caps or bottom halves. The big-end is split at right angles to the connecting-rod axis, the bearing cap being secured by four bolts. The design is such that the-connecting rods can be withdrawn through the Cylinder bores for dismantling purposes.

To assist in maintenance, and to reduce the tendency to ,disturtion such as a one-piece cylinder head may promote, two separate heads are used These are fitted with overhead valves, operated by a high-mounted camshaft. sup, ported in seven bearings. Silicon chrome steel is used for the valves, the exhaust valves having renewable hardened steel seatings; valve springs are of the dual type.

As previously mentioned, a toroidal." cup : type of combustion chamber is formed in the crown of each piston, which is fitted with four compression rings and two scraper or control rings. The tubular gudgeon pins are fully floating and are located by means of circlips of deep section. The compression ratio is 1.5.6 to 1.

All the auxiliary units, with the exception of the starter motor, together with the inlet and exhaust manifolds, are arranged on the near side of the engine. The fuel pump is of the valveless. constant-stroke, single-plunger-per-cylinder type. It is fitted with a centrifugal governor, and an air chamber is incorporated in order to cancel out pulsations in the fuel line.'

The feed to the pump is via an Autovac of 2. gallons capacity. There are two filters of ample capacity arranged between the fuel tank and the pump.

40 Spring-loaded, closed-type atomizers are employed, and these are arranged in an accessible position on the outside of the head.

• 33

--1 A positively driven centrifugal-type water pump and a four-bladed fan are responsible for the cooling, the fan being belt driven off an extension of the water-pump rotor shaft.

This Crossley 8.6-litre engine, which is known asthe Type 7, forms the power unit in the company's double-deck

bus chassis, of which the following are brief details. If the gearbox fitted be of the constant-mesh type the drive is taken through a single-plate clutch, having cork-Insert friction plates and a resilient hub mounting for the driver, plate. Top, third and second gears are arranged as constant-mesh, the first gear -being of the orthodox sliding-spur type. The gearbox provides the following ratios: 3.86, 2.39, 1.44 and 1 to I forward, and 4.67 to 1 reverse.

With a synchromesh gearbox, the clutch is of the twin. disc type with a separate hub for each disc. In this case the ratios provided are: First. 3.44; second, 2.54; third, 1.47; and top, 1 to 1, with a 3.19 to 1 reverse, From the gearbox, the drive is taken through an open two-piece tubular propeller shaft, the forward section being of the Layrub type to give a cushioned drive, and the rear section a Hardy Spicer shaft, There is, of course, a substantial centre bearing

Offset Worm Drive, td Axle An under-driven .worm-gear rear axle is employed, the axle pot being a one-piece steel stamping, with the pot

offset to the near side of the chassis. The gear ratio is 6 to 1. The wheel hubs are mounted on taper-roller bearings, and there is a large ball-thrust bearing 'provided for the worm and worm wheel. There is a captive-cap-type oil filler and a separate dipstick oil-level gauge.

The brake drums are 17 in, in diameter, the shoes at the rear being 6 ins, wide and those on the front wheels 3 ins, wide, Foot-brake application is in conjunction

with a vacuum-servo system, there being one main, servo cylinder for the rear wheels and two auxiliary cylinders for the front wbeels.

In, conjunction with the Marles double-roller-type steering gear, there is a 21-in, diameter wheel. Semi-elliptic springs are used, front and rear, those at the rear bring underslung; only one type of shackle bolt is used throughout.

The steel disc wheels are equipped with 9.75 by 20 lowpressure tyres at the front and 9.00 by 20 low-pressure tyres in twin form at the rear.

Regarding starting and lighting, the standard specification includes a C.A.V. 24-volt dynamo.,, Exide or Oldham lead and acid battery of 180 amp.-hr. capacity, C A.V. axial starter motor, and the usual switchboard and lamps. If desired, Simms components can be fitted as an alternative, as can a 12-volt system.