Water Circulation in Loco.-type Boilers.

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

A New Attachment for the Improvement of the Water Circulation Reduces the Time Needed for Raising Steam by 75 Per Cent. Fuel Economy and Modified Formation of Scale Assured.

Important considerations in a boiler, from the point of view of efficiency, are the degree and rapidity of circulation of the water while heat is being applied. Steam generators of the water-tube type are designed so as to possess this property of rapid circulation.

_ Heat is transferred through water, not by -being conducted fronArte particle to the next, but by what is termed conveiction. In respect of this property of heat transference, liquids in general differ from solids. If heat is applied to one side of a plate, the temperature of that side immediately rises, and the0eat is gradually conieyedWrom• particle to particle through the thickness of the plate, the rate of transference depending on the degree of heat applied and on the material of the plate. With copper or iron, for example, the transference would be comparatively rapid ; with wood or bone, it would be slow. If a body of water in the form of a plate could be made to receive heat in the same way, it would be, discovered that the rate of conduction was practically nil.

When heat is applied to water, the temperature of the water adjacent to the heat-conveying medium rises, causing it to expand and, in_ consequence, diminish in density ; itIthen rises through any colder w"her whiCh may be above it, its place being taken by fresh, cool water which is heated in its turn, and which the

rises, being itself replaced by more of the cold water. This prqcess continues, and 5 the resulting movement of the water createswhat are known as convection currents. The activity, of these currents depends upon the formation, of the veSsel containing the water, and the position of • the point at which heat is applied. They are of paramount impor

thrice in a boiler, affecting its rate of steaming, its economy, and the tendency for scale to settle at any one point rather than at any other.

Until the advent of water-tube boilers, no great attention had been paid to the matter of efficient circulation, although, naturally, this very essential feature hid not been entirely ignored ; when fuel was cheap, the need for economy was not urgent.

The modern call for increased efficiency and economy of fuel has caused inventors once more to turn their minds to this problem, partly with a view to creating improvements in existing boilers, and, by slight modifications of existing designs, to in. crease the efficiency of those steam generators which are for various reasons considered to be standard units. One such device of Proven worth, to judge by the number of repeat orders and by the important companies which are adopting it, is known as the Ross-Schofield patent circulator. It is applicable in its various forms to all the principal types of steam generators, but more particularly to Lancashire and Cornish boilers, to marine boilers, and to those of the horizontal type. The latter are familiar to most of our readers as being widely employed in steam wagons and tractors.

. As regards running costs, the steam wagon, taking it all round, compares favourably with any known means of road transport, but there is no doubt that its efficiency as regards steam raised per lb. of coal or coke is, as a rule, low. Furthermore, when comparing it with other road vehicles, and particularly with the internal-combustion-engined machine, a point which frequently tells against it is the time needed to raise steam from cold before it is ready to start.

ny method of increasing the efficiency of the water circulation within the boiler, besides economizing ih' fuel, also tends to increase facilities which the boiler possesses for rapid steam-raising. The interest which the Ross-Schofield circulatoi has for the average steam-wagOn usir cannot, therefore, be gainsaid, and the following 'description will, we arc certain, be read by many with great interest.

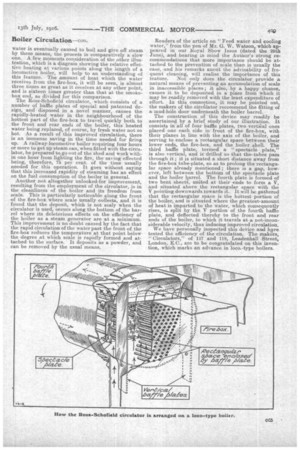

Before proceeding to any explanation of the device, it may be as well—since numbersof our readers, although steam-wagon users, are not intimately acqiiainted-with the internal construction of thejooilers on their machines—if we endeavour in a few words to demonstrate the construction of. a locomotive boiler of the type which is embodied in the construction of the majority of steam wagons. Reference to our illustration of the circulator will be of assistance in following this explanation.

The'boiler may broadly be said to consist of two compartments, one for fire, the other for water. That One for fire extends from the rear of the boiler, from the fire-door and fire-box, through the many tubes of the boiler to the smoke-box and chimney, which complete this compartment. The water space surrounds the fire-box and the tubes,' and, is contained within the barrel of the boiler and that outer casing about the fire-box. From a consideration of our opening paragraphs on convection currents, it will be seen that the circulation of the water in a boiler on these lines is, in a sense, haphazard. The greatest heat is given off at the fire-box, but it can readily be conceived that the water near the fire-box could circulate round it without affecting to an appreciable degree the water in the barrel. This barrel is heated to a less degree by the hot gases passing along the inside of the tubes, and although, of course, the

water is eventually caused to boil and give off steam by these means, the proceas is comparatively a slow one. A few moments consideration of the other illustration, which is a diagram showing the relative effective heating at various points along the length of a locomotive boiler, will help to an understanding of this feature.. The amount of heat which the water receives from the fire-box, it will be seen, is almost three times as great as it receives at any other point, and is sixteen times greater than that at the smokebox end, as divided for this comparison. The Ross-Schofield circulator, which consists of a number of baffle plates of special and patented design, and disposed in a novel manner, causes the rapidly-heated water in the neighbourhood of the hottest part of the fire-box to travel quickly both to the front and rear ends of the boiler, this heated water being replaced, of course, by fresh water not so hot. As a result of this improved circulation, there is an immense saving in the time needed for firing up. A railway-locomotive boiler requiring four hours or more to get up steam can, when fitted with the circulator, be prepared to go out of the shed and work within one hour from lighting the fire, the saving effected being, therefore, 75 per •cent. of the time usually needed for this operation. It goes without saying that this increased rapidity of steaming has an effect on the fuel consumption of the boiler in general.

Another not altogether unlooked-for improvement, resulting from the employment of the circulator, is in the cleanliness of the boiler and its freedom from scale. This is particularly noticeable along the front of the fire-box where scale usually collects, and it is found that the deposit, which is not scaly when the circulator is used, occurs along the bottom of the barrel where its deleterious effects on the efficiency of the boiler as a steam generator are at a minimum. This improvement is no ,doubt caused by the fact that the rapid circulation of the water past the front of the fire-box reduces the temperature at that point below the degree at which scale is rapidly formed and attached to the surface. It deposits as a powder, and can be removed by the usual means. Readers of the article on "Feed water and cooling water," from the pen of Mr. G. W. Watson, which appeared in our Itoyal Show Issue (dated the 29th June), and bearing in mind the Author's strong recommendations that more importance should be attached to the prevention of scale than is usually the case, and his remarks anent the advisability of frequent cleaning, will realise the importance of this

feature. Not only does the circulator provide a natural means of preventing an accumulation of scale in inaccessible places; it also, by a happy chance, causes it to be deposited in a place from which it may be readily removed with the least expenditure of effort. In this connection, it may be pointed out, the makers of the circulator recommend the gang of a mud-hole door underneath the boiler barrel.

The construction of this device may readily be ascertained by a brief study of our illustration. It consists in all of four baffle plates, two vertilal ones placed one each side in front of the fire-box, with their planes in line with the axis of the boiler, and serving to enclose a rectangular space between their lower ends, the fire-box, and the boiler shell. The third baffle plate, termeda "spectacle plate," is also vertical, and is drilled so that the.tubes pass through it ; it is situated a short distance away from the fire-box tube-plate, so as to prolong the rectangular space already mentioned ; there is a gap, however, left between the bottom of the spectacle plate and the boiler barrel. The fourth plate is formed of two bent sheets, united at their ends to form a V, and situated above the rectangular space with the V pointing downwards towards it. It will be gathered that the rectangular space is the hottest portion of the boiler, and is situated where the greatest amount of heat is imparted to. the water, which consequently rises, is split by the V portion of the fourth baffle plate, and deflected thereby to the front and rear ends of the boiler, to which it travels at a not-inconsiderable velocity, thus inducing improved circulation.

We have personally inspected this device mad have tested the efficiency of the circulation. The makers, "Circulators," of 117 and 118, Leadenhall Street, London, E.G., are to be congratulated on this invention, which marks an advance in loco.-type boilers.