A TRACTOR TO MEET INDUSTRIAL NEEDS.

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

The New McCormick-Deering Road Tractor Marketed by the International Harvester Co. of Great Britain, Ltd„ for Commercial, Industrial and Municipal Work.

• Ull.1NG recent years there has • been a considerable increase in the application of the petrol-propelled tractor for road use in hauling pantechnicons, trailers carrying heavy loads, such as paper, and for manceuvring vehicles in confined spaces, but, so far, the-number of tractors suitable for these classes of work has been extremely limited, for the Fordson, Austin and British-Wallis may be considered as the only representatives, and of these not all were originally designed purely for road work, but more to meet the needs of the agriculturist.

The International Harvester Co. of Great Britain, Ltd., 80, Finsbury Pavement, Loudon E.C.2, are now, however, placing upon the market a most interesting type of industrial tractor, which has been undergoing arduous tests for many months past. It is being sold at /the reasonable price of £295, delivered to the nearest station.

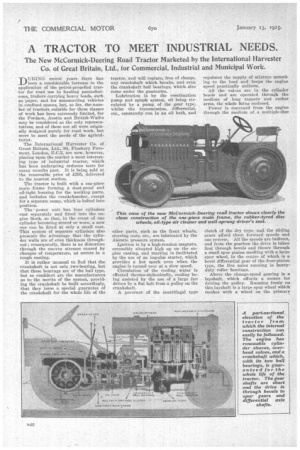

The tractor is built with a one-piece main frame forming a dust-proof and oil-tight housing for the working parts, and includes the crankehamber, except for a separate sump, which is bolted into position.

The power unit has four cylinders cast separately and fitted into the engine block, so that, in the event of one cylinder becoming scored or worn, a new one can be fitted at only a small cost. This system of separate cylinders also presents the advantage that the cylinder walls are of even thickness throughout ; consequently, there is no distortion through the uneven stresses caused by changes of temperature, aS occurs in a rough casting.

It is rather unusual to find that the crankshaft is not only .two-bearing, but that these bearings are of the ball type, but so confident are the manufacturers as to the merits of the system, providing the crankshaft be built accordingly, that they issue a special guarantee of the crankshaft for the whole life of the tractor, and will replace, free of charge, any crankshaft which breaks, and even the crankshaft ball bearings, which also come under the guarantee.

Lubrication is by the combination pump and splash system, oil being circulated by a pump of the gear type, whilst the transmission, differential, etc., constantly run in an oil bath, and other parts, such as the front wheels, steering nuts, etc., are lubricated by the Alemite pressure system Ignition is by a high-tension magneto, accessibly situated high up on the engine casting, and starting is facilitated by the use of an impulse starter, which provide.;a hot spark even when the engine is turned over at a slow speed.

Circulation of the cooling water is effected thermo-siphonically, cooling being assisted by the use of a large fan driven by a flat belt from a pulley on the crankshaft.

A governor of the centrifugal type regulates the supply of mixture according to the load and keeps the engine speed practically uniform.

All the valves are in the cylinder heads and are operated through the medium of long tappets and rocker arms, the whole liking enclosed.

Power is conveyed from the engine through the medium of a multiple-disc clutch of the dry type, and the sliding gears afford three forward speeds and one reverse. All the speeds are 'indirect, and from the gearbox the drive is taken first through bevels and thence through a small spur pinion meshing with a large spur wheel, in the centre of which is a bevel differential gear of the four-pinion type, the live axles running in heavyduty roller bearings.

Above the change-speed gearing is a layshaft, which affords a means for driving the pulley. Bunning freely on this layshaft is a large spur wheel which meshes with a wheel on the primary shaft, whilst a dog clutch, sliding on splines on the pulley layshaft, can be brought into mesh with the idler wheel by means of a special lever. The drive is then taken through the layshaft and a pair of bevel wheels to the pulley.

Two sets of brakes are employed, a hand brake operating on the countershaft and a foot-controlled internalexpanding brake acting on the rear wheels.

The machine is spring-mounted at the front, springs of the coil type being employed.

Disc wheels are used both at the front and at the rear, those at the back being equipped with 40-in. by 5-iu, solid rubber tyres, whilst at the front the tyres used are 27 ins. by 3iins. The rear wheels are so constructed that dual tyres can be used if required. The dual tyres are 5-in, wide and are carried on special disc wheels, which are bolted to the ordinary rear wheels.

The special equipment includes electric headlights, dynamo and battery, the 'dual tyres and wheels to which we have just referred, a belt pulley attachment, power take-off and extension rims with Jugs, etc. This equipment is supplied at an extra cost, but the regular equipment includes a comfortable spring seat, throttle governor, oil-type air cleaner and two sets of brakes, etc. The forward speeds of this tractor are : 2, 4 and 10 m.p.h. at the governed engine speeds, and it is interesting to note that 22 ball and roller bearings are used throughout the chassis.