DESIGNED for DURABILITY

Page 35

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

The New Walker

.5-tormer MY first impression of the Walkei 5-ton overseas chassis (described in The Commercial Motor ' last week) was the sturdiness of 'the. construction of the frame, spring shackling and other component parts. The side members, which are 23 ft. long, are shaped to give Maximum support at the spring anchorage. The spring brackets are made with widely spaced bolt holes to provide a strong support.

This chassis has been designed from long experience gained in constructing municipal vehicles which have to withstand continuous hard service under all manner of conditions Walker Brothers (Wigan), Ltd., is at present producing the overseas chassis on assembly lines similar to those of the Pagefield and Walker municipal vehicles, most of the component parts of which are incorporated in the overseas model.

The latest version of the Perkins P.6 70 b.h.p engine is used as the power unit and is supported in the frame at three points on composite pads of balata belting and rubber sheeting. These form a semi-rigid suspension system which effectively absorbs engine-to-frame vibration at all speeds.

Mounted integrally with the engine, a Meadows large-diameter clutch and 9D four-speed-andreverse gearbox add to the impressive sturdiness of the design. A single dry-plate unit, the clutch frictional area totals 226 sq. ins. Clutch controls are positioned for quick adjustment, and the friction unit is readily accessible for inspection and maintenance.

Noticeably quiet in operation, the gearbox is of unit construction and incorporates large-diameter bearings and robust spur-pattern form-ground gears to give prolonged service with the minimum attention. Provision is made for a power take-off. The convenient gear-selector lever is spherically mounted directly on the gearbox cover.

Supported by a bearing at the centre, a two-piece propeller shaft, fitted with Hardy Spicer needleroller couplings, transmits the drive to the spiral-bevel unit of the Moss fully floating rear axle. The spiral-bevel drive and the differential unit are carried by ball and taper-roller bearings, the differential unit being. moulded in a steel casing for easy detachment. Well-proportioned axle shafts, made from nickel-chrome 60-65-ton steel, convey the drive to

the wheels. A thud-drive ratio of 7 to l is standardized.

Of Kirkstall manufacture, the front-axle beam is an H-section nickel-steel drop stamping. Conforming with the requirements of many overseas countries, the Bishop cam-and-roller steering is bolted to the left-hand frame side member. This steering provides light and accurate control on the road.

The frame side members, made from high-tensile steel of 7-in. by 2i-in. by /-in section, are well braced by four sturdy pressed-steel cross-members and two tubular members. In effect, the engine rear mounting forms an additional tie to the side members. Every opportunity has been taken of producing a wide frame and of spacing the spring anchorages as widely as possible, thus combating any tendency of the chassis to roll on corners.

Single front and twin rear wheels, shod with 34-in. by 7-in_ tyres, are used, the detachable wheel discs being mounted on hubs running on taper-roller bearings.

High-efficiency braking is attained with the Girling wheel units, which are operated through a Lockheed system and a Clayton Dewandre servo. The combined Clayton Dewand re-Lockheed unit is accessibly mounted on the outside of the frame. A gravity tank, located in the cab, is used to maintain the level of brake fluid. The push-on hand brake is actuated through mechanical means to the rear axle, and an equalizing arrangement is incorporated in the linkage. The road test was started in weather which was far from pleasant, and as the day wore on we ran into heavy rain and a keen wind which kept the atmospheric temperature down to 43-44 degrees F. As we left the Pagefield Works, a section of unmade road provided an opportunity of testing the suspension. Of

course, it is difficult to judge the possibility of chassis roll without the body being fitted, but the Walker rode all the potholes without undue bounce.

The first part of the course took us towards the coast in search of Parbold Hill, which is a half-mile stretch with an average gradient of 1 in 8, and a maximum of 1 in 6. Running down the hill, the brakes were used to keep the speed to 35 m.p.h., and by the time Parbold village was reached the drums were showing signs of warming up. Nevertheless, the brakes were still effective and were quite up to an emergency application.

Radiator temperature at the foot of the hill was 132 degrees F. Later readings taken during normal running showed a variation between 130-134 degrees F. The hill was climbed for the majorpart in second gear, first gear being used for the steeper gradient. A stopstart test made on this section produced a smooth take-off without trace of transmission whip or clutch judder. The radiator temperature showed a rise of 18 degrees at the end of the climb.

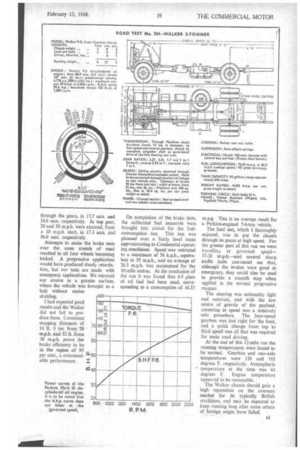

We continued on the course to the dual carriageway of the PrestonLiverpool road for the acceleration tests. Here it was found that the gear ratios were well matched to the engine and the results were slightly above average for this class of vehicle. From a standing start, 20 and 30 m.p.h. were reached, through the gears, in 17.7 secs. and 34.6 secs. respectively. In top gear, 20 and 30 m.p.h. were attained, from a 10 m.p.h. start, in 17.3 secs. and 36.0 secs. respectively.

Attempts to make the brake tests over the same stretch of road resulted in all four wheels becoming locked. A progressive application would have produced steady retardation, but our tests are made with emergency applications. We retraced -our course to a granite surface, where the vehicle was brought to a halt without undue skidding.

I had expected good results and the Walker did not fail to produce them. Consistent stopping distances of 14 ft 3 iris. from 20 -m.p.h. and 32 ft. from 30 m.p.h. prove the brake efficiency to be in the region of 9$ per cent, a commend able performance. I On completion of the brake tests, the calibrated fuel measures were brought into circuit for the fuelconsumption -test. This test was planned over a fairly level route approximating to Continental operating conditions. Speed was restricted to a maximum of 56 k.p.h., equivalent to 35 m.p.h., 'and an average of 26.3 m.p.h. was maintained for the 10-mile conrse. At the conclusion of the run it was found that 4.9 pints of oil fuel had been ase.d, corresponding to a consumption of 16.33 m.p.g. This is an average result for a Per'kins-engined 5-6-ton vehicle.

The final test., which I thoroughly enjoyed, was to put the chassis through its paces at high speed. For the greater part of this run we were travelling at governed speed37-38 utp.ch.—and several sharp traffic halts convinced me that, although the brakes were good in emergency, they could also be used to provide a smooth stop when applied in the normal progressive manner.

The steering was noticeably light and accurate, and with the low centre of gravity of the payload, cornering at speed was a pelatively safe procedure. The four-speed gearbox was just right for the load, and a quick change from top to third speed was all that was required for main road driving.

At the end of this 12-mile run the running temperatures were found to be normal. Gearbox and rear-axle temperatures were ' 120 •and 118 degrees F. respectively. Atmospheric temperature at the time was 44 degrees F. Engine temperature appeared to be reasonable.

The Walker chassis should gain a high reputation on the overseas market for its typically British sturdiness, and may be expected to keep running long after some others of foreign origin have failed.