From the Dream 130er

Page 64

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

by Graham Montgomerie by Graham Montgomerie

I'S NOT the usual policy of ommercial Motor to stray into -le domain of military vehicles

general and Chieftain battle inks in particular, but in the phere of design where there is Dmetimes a spin-off between iilitary and civilian usage. A ood illustration of this overlaping is the mixed flow cooling in developed by Airscrew owden.

This Weybridge company is eginning to market such a fan, iitially developed for the Doling system of the aforemenoned piece of military ironiongery, and claims that it's lore efficient than the convenonal type.

I recently spent a day at Weyridge talking to the company's ales manager John Baxter bout the commercial applicaon for the fan design.

jgj

Airscrew started by making Doden propellors at a factory 1Weybridge with the site being iosen because it was conveent for the Brooklands race ack where much of the re:arch work was carried out.

In fact, the company was so iccessful that by the mid-Thiris over 85 per cent of the -opellors for British aircraft ere of Airscrew manufacture. During the war the company's intribution was invaluable, .oducing over 2,000 propellors aweek.

After the war, the company oved into more peaceful areas id made ventilation fans for ind tunnels, engine-testing lys and so on.

The Airscrew Howden cornny is now organised into three visions — heat transfer, 3rine and special applications with the total output being Dund 1,000 fans per week.

The Heat transfer division proices heat exchangers and oling towers, with Gatwick rport one notable customer.

Fans from the marine division a used for engine-room vent] as well as for gas-freeing the Ids of tankers, ks an example of a product m the special applications 'ision, the fans for cooling ncorde's Dunlop disc brakes re developed by Airscrew. The mixed-flow cooling fan was developed by Airscrew specifically for military application in the Chieftain battle tank. As the whole working of the fan is wrapped up with this particular design concept, it is worth explaining at this point just what is meant by a "mixed flow" fan.

Fans can normally be categorised as "axial" or "centrifugal" with the former producing a high volume of air, but at comparatively low pressure„ while the centrifugal design has characteristics which are completely opposite (that is, high pressure and low volume).

Automotive cooling fans are of the axial type and these are limited in performance by the speed of the engine which they are meant to cool. In other words, it can be made more efficient in terms of pressure by simply running it faster; but then there are all sorts of dubious side effects, like increased noise and power absorption as well as the installation problems which can crop up if the fan drive has to be geared up relative to the crankshaft or water-pump speed.

The centrifugal fan, on the other hand, is capable of delivering at high pressure, but its large size precludes it from being used in road vehicles.

So the mixed flow fan was developed which, as its name suggests, has flow characteristics which are a cross between the axial and centrifugal designs.

With the Airscrew Howden fan, the leading sections of the blades resemble those of the axial type whereas the trailing edges are more closely related to a centrifugal impellor. These trailing edges are curved backwards increasing the pressure of the discharge air which leaves on a swirling conical path but may be ducted efficiently in almost any direction.

So the combination enables the mixed flow fan to handle the volume flow of the axial while delivering the pressure normally associated with a centrifugal design. As mentioned, the Airscrew mixed flow fan was developed for tank application where the cooling air was needed to follow a tortuous inlet path because of the number of baffles necessary to protect against enemy projectiles. Because of the complicated flow path, a conventional fan just could not draw the air in fast enough.

Where sizeable diesel engines are concerned — the 1,200 plus horsepower of the Chieftain's Rolls-Royce V12, for instance — the power absorbed by the fan can be frightening. As a measure of the success of Airscrew, the mixed flow fan brought this absorption figure down from 30 to eight per cent. This also resulted in noise reduction as well as the obvious benefit in fuel figures.

By definition a tank is a robust animal, so the fan needed to be built along the same lines with the result that it was cast in aluminium alloy. This was fine as far as strength in its individual application was concerned, but the resulting component was, not surprisingly, heavy and expensive.

Civilian market The aerodynamic characteristics of the fan were ideal for automotive application on the civilian market, but the actual hardware was somewhat less than ideal for a heavy lorry. Thus Airscrew took the basic design and tailored it to suit the civilian market by fabricating the fan from sheet aluminium and steel.

Airscrew claims that the mixed flow design allows a smaller and quieter fan to be used and, because of its increased efficiency over the axial type, it can also mean more compact radiators.

Additionally it gives the designer a greater degree of flexibility with the overall cooling system — the emphasis is on the word "system". Because of the fan's non-stalling characteristics and flexible discharge direction, it is possible, for example, to have the fan hard up against a bulkhead where it can still suck air through as the air is moved out radially.

The first of the lightweight "civilian" fans to go into produc tion was the 630mm (24.8in) outside diameter unit — designated 475 MP 6 — which has already undergone trials in the 465kW (625bhp) Scam mell Commander. The original design of this vehicle needed a very big radiator and a hefty fan to cope with the cooling requirements not only of the engine but also the retarder.

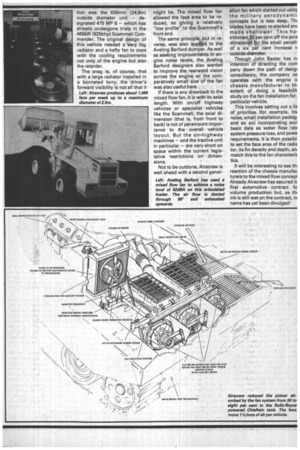

The snag is, of course, that with a large radiator installed in a bonneted lorry, the driver's forward visibility is not all that it Left: Airscrew produces about 1,000 fans per week up to a maximum diameter of 2.5m. _ might be. The mixed flow fan allowed the face area to be reduced, so giving a relatively "low profile" to the Scammell's' front end.

The same principle, but in reverse, was also apptfed to the Aveling Barford dumper. As well as seeking improvements in en gine noise levels, the Aveling Barford designers also wanted to improve the rearward vision across the engine so the comparatively small size of the fan was also useful here.

If there is any drawback to the mixed flow fan, it is with its axial length. With on/off highway vehicles or specialist vehicles like the Scammell, the axial di mension (that is, from front to back) is not of paramount importance to the overall vehicle layout. But the on-highway machines — and the tractive unit in particular — are very short on space within the current legislative restrictions on dimensions.

Not to be outdone, Airscrew is well ahead with a second gener Left: Aveling Barford has used a mixed flow fan to achieve a noise level of 82dBA on this articulated loader. The air flow is ducted through 90' and exhausted upwards. ation fan which started out usinc the military aerodynamic concepts but is less deep. Th( blades have been re-stacked an made shallower. This ha: trimmed 25 per cent off the axia dimension for the small penalt of a six per cent increase ir outside diameter.

• Though „John Baxter has nc intention of directing the corn pany down the path of desigi consultancy, the company co operates with the engine o chassis manufacturer to th extent of . doing a feasibilit study on the fan installation for particular vehicle.

This involves setting out a us of priorities (for example, lov noise, small installation packag and so on) incorporating sucl basic data as water flow ratE system pressure loss, and powe requirements. It is then possibl to set the face area of the radio tor, its fin density and depth, am match this to the fan characteris. tics.

It will be interesting to see thi reaction of the chassis manufac turers to the mixed flow concepi Already Airscrew has secured it: first automotive contract fo volume production but, as thc ink is still wet on the contract, nc name has yet been divulged!