Starter motors, I

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

UNLIKE the steam engine, where power is available immediately the throttle is opened, the internal combustion engine has to be turned over at more than 30 to 30rpm before it will start.

In the early days of motoring a starting handle was provided so that the engine could be cranked by hand. On cold mornings, two or three men might be needed on the starting handle of a lorry_ trying to get it to start and broken wrists sometimes resulted, when the engine backfired.

On all modern vehicles an electric motor is fitted for starting purposes.

The starter motor is very similar in construction to the dy namo. On some early vehicles a "dynamotor" was fitted, and this one machine was so designed that it acted as a starter and then when the engine was running it changed its function to a dy namo for charging the battery. This system is now obsolete and a separate starter motor, one type of which is illustrated in Figure 1, is fitted.

Considerable power is needed to crank an engine on a cold morning. On a light vehicle, fitted with a 12 volt electrical system, a current higher than 250 amperes is required. On a diesel engine, with a 24 volt system there may be a current draw as high as 600 amps.

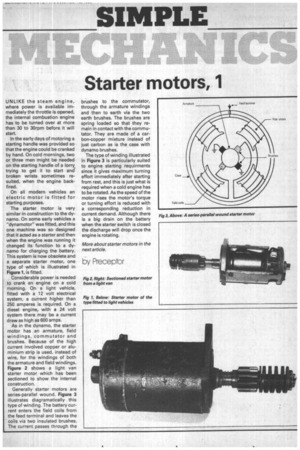

As in the dynamo, the starter motor has an armature, field windings. commutator and brushes. Because of the high current involved copper or alu minium strip is used, instead of wire, for the windings of both the armature and field windings.

Figure 2 shows a light van starter motor which has been sectioned to show the internal construction.

Generally starter motors are series-parallel. wound. Figure 3 illustrates diagramatically this type of winding. The battery current enters the field coils from the feed terminal and leaves the coils via two insulated brushes. The current passes through the brushes to the commutator, through the armature windings and then to earth via the two earth brushes. The brushes are spring loaded so that they remain in contact with the commutator. They are made of a carbon-copper mixture instead of just carbon as is the case with dynamo brushes.

The type of winding illustrated in Figure 3 is particularly suited to engine starting requirments since it gives maximum turning effort immediately after starting from rest, and this is just what is required when a cold engine has to be rotated. As the speed of the motor rises the motor's torque or turning effort is reduced with a corresponding reduction in current demand, Although there is a big drain on the battery when the starter switch is closed the discharge will drop once the engine is rotating.

More about starter motors in the next article.

by Preceptor