NEW "FOUR" OIN "RIAL

Page 68

Page 69

Page 70

Page 73

If you've noticed an error in this article please click here to report it so we can fix it.

By John F. Moon,

A.M.I.R.T.E.

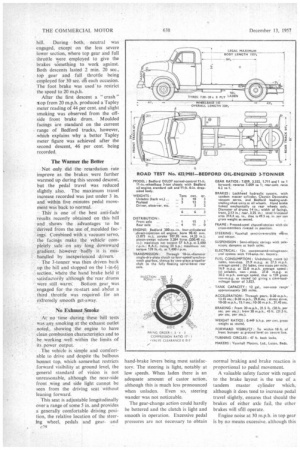

ALTHOUGH nominally a 3-tonner, the standard Bedford oil-engined drop-sided truck can carry a payload of, over 3-1 tons without exceeding the maximum recommended grOss-weight figure of 6 tons 3* cwt., plus driver and passengers. Thus, the fuel-consumption rate reCorded on test cannot be compared directly with the results obtained with 3-tonners of other makes.

Nevertheless, the test, the fist to be conducted with this new Vauxhall

made four-cylindered oil engine does show this unit to be economical, partieularly in terms of payload-ton-m.p.g. its primary advantages however, are the low 'purchase price (when compared with the cost of the unit previously offered in this chassis), and the interchangeability of certain of its parts with those of the Bedford sixcylindered oil engine.

Introduced on October 4, and described in The Commercial Motor that day, the Bedford 200-cu.-in, oil engine is a four-cylindered version of the 300-cu.-in. units announced last February. With a cubic capacity of 3,284 litres it is slightly smaller than other four-cylindered oil engines in this power bracket, despite which it compares favourably in respect of b.h.p. and torque outputs.

The alternative in this chassis is an 86 b.h.p. six-cylindered petrol engine. Naturally, this unit is longer than the four-cylindered oil engine, but to retain the same gearbox location in the standard chassis (andithus use standard propeller shafts), the oil engine is set back in the frame so that the clutch of each engine lies in the same transverse plane. This results in a rather large radiator cowl and someWhat lengthy top and bottom 'hoses, which, I ant assured, are no more likely to fracture than shorter hoses.

Four-point mounting is employed for the engine-gearbox unit, with two c26 sandwich-type rubbers in compression and shear at the front, and a double rubber shear-type mounting at each side of the bell housing at the rear. The vehicle tested had an earlier type of front Mounting which caused idling roughness; indeed, the dash-mounted idling control had to be screwed out to give a speed of about 600 r.p.m. before the engine 'would idle smoothly.

Since my test, the mountings on the chassis have been changed to the current production type, and it is now possible to set the idling speed much lower without undue vibration in the cab. Even so, idling is by no means smooth.

Basically the Bedford D3L chassis has been tittle changed in recent years, except. for the new power units and improved gearbox and rear axle. The suspension, however, now includes telescopic dampers as standard on the front axle and as optional equipment on the rear axle, these being fitted to the vehicle tested. A choice of axle ratios is available with this chassis, that fitted to the test vehicle biting the -lower one---6.2 to I.

The alternative • ratio is 5.286 to 1, but this is recommended only when the vehicle will be operated in relatively flat districts. With the low axle ralio the maximum speed is 46 m.p.h., which is sufficient for operation in this country, and the only possible drawback with the lower ratio is that fuel consumption when unladen will be slightly heavicr Although externally unchanged, the cab has a new mounting arrangement. As before, the cab and front-end assembly is carried on a sub-frame, but this has been strengthened and a revised form of three-point mounting has been adopted. This consists of one rubber mounting at the rear and single rubbers at each side of the sub-frame amidships. These forward mountings are close to where the control pedals pass through the floor and the arrangement reduces movemeni between the cab floor, pedals and gear lever when travelling over rough ground. The previous mounting layout had a single rubber pivot at the front of the sub-frame and two pads at the rear of the cab.

Complete with the standard 11-ft. 6-in, drop-sided body, the 3-tanner tested had a kerb weight of 2 tons 101 cwt., making it possible to add a test load of 3 tons 12-1 cwt. without exceeding the maximum recommended -gross weight.

With myself and Mr_ Guy Tidbury, of the Vauxhall experimental department, the vehicle was tested at gross weight of 6 tons cwt. The rear tyres were slightly overloaded, although the test weights were evenly distributed down the length of the body.

For the first tests I drove out to Barton-in-the-Clay, where there is a good stretch of level firm-surfaced road suitable for braking and acceleration tests.

Braking tests revealed a slight delay in the system, which accounted for a difference of 15 per cent. when making emergency stops at 20 m.p.h. and 10 per cent. when braking from 30 m.p.h. Nevertheless, retardation under such conditions was reasonably smooth and wheel locking did not occur. The hand brake proved to be extremely effective, an average figure of 36 per cent., as recorded on the Tapley meter, being obtained from 20 m.p.h.

For the standing-start acceleration tests, second, third and top gears only were used, although on one run I started in bottom gear to see whether this would produce faster times, which it did not. The acceleration times recorded were undoubtedly helped by the fast gear changes possible with the Bedford synchromesh gearbox.

Before the direct-drive acceleration test could be made the hand throttle control had to be screwed in to reduce the idling speed, because at the setting necessary to give vibration-free idling the minimum speed in top gear was 12 m.p.h. This will not occur, however, with the new front engine mountings.

The direct-drive test showed the engine to pull particularly well at low speeds, although a certain amount of roughness was noted up to 12 m.p.h. The top-gear performance is such, however, that gear changing is reduced to a minimum, and even in thick traffic third gear is usually sufficient to maintain adequate speed and acceleration.

A six-mile out-and-return undulated circuit between Barton and Clophill was used for the fuel-consumption tests, three runs being made in all. This route has in the past been sh,own to give ft3ures slightly heavier than average, which are more representative of running in hilly districts, and the axle ratio was well suited to the test conditions.

The first two runs were made carrying a full load. One circuit was completed non-stop, and during the second, two stops were made every Mile. The result obtained with two stops per mile is representative of the fuel consumption to be expected on normal delivery runs.

The figures show the Bedford to have an adequately economical non-stop performance, whilst when engaged on a delivery round it could still show an appreciable saving over the fuel costs associated with a petrol-engined vehicle of similar capacity.

On the second day of the test a third fuel-consumption run was made while carrying no test weights at all and, despite the lower axle ratio, the fuel-consumption rate recorded was not excessive. During this run it was unnecessary to use the indirect ratios except when starting from rest, wheseas during the two laden tests third gear was used on several occasions because of gradients and traffic conditions.

Bison Hill, the fmile gradient invariably used on Bedford tests, was chosen for the gradient-ability and brake-fade trials. This hill has an average gradient of 1 in 10-1and the maximum inclination is 1 in 64. The tests were conducted in an ambient temperature of 42' F.

A coolant-temperature check before making the climb showed the water in the radiator top tank to be at 158' F.. and a reasonably fast climb occupying 4 min. 26 sec. produced a rise of only 7* F. During this climb it was necessary to use bottom gear for 1 min. 23 sec. The test showed more than adequate gradient-ability and engine cooling for this type of operation when fully laden.

Two fade tests were made down the Cr hill. During both, neutral was engaged, except on the less severe lower section, where top gear and full throttle were employed to give the brakes something to work against. Both descents lasted 2 min. 20 sec., top gear and full throttle being employed for 30 sec. o each occasion. The foot brake was used to restrict the speed to 20 m.p.h.

After the first descent a " crash " EI.op from 20 m.p.h. produced a Tapley meter reading of 44 per cent. and slight smoking was observed from the offside front brake drum. Moulded facings are standard on the current range of Bedford trucks, however, which explains why a better Tapley meter figure was achieved after the second descent, 46 per cent. being recorded.

The Warmer the Better

Not only did the retardation rate improve as the brakes were further warmed up during this second descent, but the pedal travel was reduced slightly also. The maximum travel increase recorded was just under 3 in. and within five minutes pedal movement was back to normal.

This is one of the best anti-fade results recently obtained on this hill and shows the advantages to be derived from the use of ,moulded facings. Combined with a vacuum servo, the facings make the vehicle cornplitely safe on any long downward

• gradient, however badly it is mishandled by inexperienced drivers. The 3-tormer was then driven back up the hill and stopped on the 1-in-61 section, where the hand brake held it satisfactorily although the rear drums were still warm: Bottom gear, was engaged for the re-start and about a third throttle was requiredfor an extremely smooth get-away.

No Exhaust Smoke Atno-time during these hill tests was any smoking at the exhaust outlet noted,. showing the engine to have clean combustion characteristics and to be working well within the limits of its power output.

The vehicle is simple and comfortable to drive and despite tht bulbous bonnet top, which somewhat restricts forward visibility at ground level, the general standard of vision is not unreasonable, although the near-side front .wing and side light cannot be seen from the driving seat 'without leaning forward.

This seat is adjustable longitudinally over a range of some 5 in. and provides a generally comfortable driving position, the relative location of the steering wheel, pedals and gear-and hand-brake levers being Most satisfactory. The steering is light, notably at low speeds. When laden there is an adequate amount of castor action, although this is much less pronounced when unladen. Even so, steering wander was not noticeable.

The gear-change action could hardly be bettered and the clutch is light and smooth in operation. Excessive pedal pressures are not necessary to obtain normal braking and brake reaction is proportional to pedal movement.

A valuable safety factor with regard to the brake layout is the use of a tandem master cylinder which, although it does tend to increase pedal travel slightly, ensures that should the brakes of either axle fail, the other brakes will still operate.

Engine noise at 30 m.p.h. in top gear is by no means excessive. although this

is not the quietest four-cylindered oil engine on the road. Even at 40 m.p.h., however, conversation in the cab at little more than normal level is possible.

When running laden the suspension gives a commendably good ride, although admittedly this would partly be helped by the rear dampers. When unladen also the ride is reasonable; although a little hard, it cannot be termed harsh or uncomfortable.

Cab fittings include an ash-tray and interior light as standard, and optional equipment fitted to the test vehicle included an effective fresh-air heater and de-mister unit, and near-side driving mirror.

Good Accessibility A series of maintenance tasks showed that good access to the engine is given when the alligator-type bonnet is raised, this being safely supported. With the bonnet up (in 41 sec.) 1 spent 16 sec. checking the engine-oil level, 7 sec. checking the water level and 50 sec. verifying the oil level in the A.C. air cleaner.

There are two 6v. batteries, both under the cab floor on the left. The forward battery is reached by rolling back the floor mat and removing a plate secured by two Dzus fasteners and this operation was completed in a minute.

The other battery is beneath the

passenger seat, and although covered by a similar plate it is necessary also to remove the seat cushion (which is retained by tv0b wing. nuts) and shift the starting handle which is stowed across the plate. This all lakes 2 min. 20 sec.

As with all Bedfords, the gearbox oil level is checked through a small hole in the back of the box; the task took 1 min. 10 sec.

The rear-axle oil level was verified in 14 min. through the combined filler and level plug in the back of the banjo casing. The spare wheel tends to ham, per this operation and would make topping-up the axle even more difficult without pressure lubrication equipment

The brake-fluid reservoir is combined with the master cylinder and to check its level takes 41 min. because the driving seat, jack, wheel brace and cover plate have to be removed to obtain access to the filler plug. The two electrical fuses are motinted on the .scuttle under the bonnet and to change one takes 12 sec.

Mounted high on the right of the engine, the main fuel-filter element is easy to reach and I removed and replaced the paper-element canister in 2 min, 40 sec. The fuel injectors are not so easy to service, because they lie close to the exhaust manifold and particular difficulty arises if, as in tny case, an injector should stick.

Because of this I spent 81 min. removing No. I injector, although all the nuts and unions were disconnected within 3 min. The injector took 9 min. to replace, mainly because the exhaust manifold hampered replacement of the main feed pipe. Bleeding the system at the fuel pump took less than a minute but,' as I have previously had to remark, a larger knob could well be provided 1 on the lift-pump priming lever.

The bonnet Was lowered and secured in 2 sec., after which I Jemoved the

rear-mounted spare wheel in min. and replaced it in 1 min. 5 sec. This wheel is secured by two crankedhandled bolts.

Tools Adequate

Although the standard tool kit supplied with this chassis is not elaborate, I managed to complete all these tasks with the tools provided, with the exception of borrowing a box spanner to fit the master-cylinder reservoir plug.

The Bedford D3LD7 3-ton oilengined lorry has a basic price DI £918, additional purchase tax being, £178 16s. Id. The basic price of the chassis only is £781 and that of chassis and cab £846, purchase tax being the same as for the complete vehicle. These 'basic prices are £125 more than those for the petrol-engined versions and the purchase tax is £31 5s. greater.