THIS NEEDN'T HAPPEN IF YOU

Page 40

Page 41

Page 42

If you've noticed an error in this article please click here to report it so we can fix it.

FIT ANTI-LOCK BRAKING... by Stephen Gray

Keep your artic on the right path

BY PREVENTING the driven wheels of an articulated vehicle from locking during braking, jack-knifing can be eliminated. There is no doubt of this.

Although load-sensing valves, now widely fitted to heavy commercial vehicles especially ariics, have been shown to reduce the incidence of jack-knifing, by far the best anti-lock system is one which allows the wheel to be braked on and off in quick succession when it begins to lock.

This has the effect of retaining tyre to road adhesion thus allowing the vehicle to pull up squarely.

There are several manufacturers of such equipment on the Continent and in the USA. In the States antilock brake systems were to have been mandatory. But they're arguing the matter. In the UK, however, two main contenders have emerged: Dunlop with its Maxaret and Girling with Skidchek. Lockheed did introduce its own system, Antilok, but is seemingly not pursuing it at the moment.

With only two systems available to the UK operator the choice lies with which set of criteria suits his requirements. C/14 has been looking at the two rivals to see what the state of the art is.

Dunlop was unquestionably first in the anti-lock field with Maxaret. Developed from its extensive work on aeroplane wheel brakes, Maxaret was first applied to a road vehicle in 1964 when it was fitted to an air over hydraulic brake system.

Tests with this prototype established the basic principle which Dunlop applies to full air braking only. In -those days the sensing was mechanical, and this brought problems. It was

very difficult to fit the device easily to a vehicle, so in 1 968 the Mark 3 version with electronic sensing was introduced.

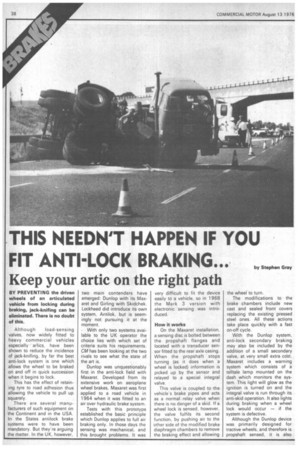

How it works On the Maxaret installation, a sensing disc is bolted between the propshaft flanges and located with a transducer sensor fitted to the rear axle casing. When the propshaft stops turning (as it does when a wheel is locked) information is picked up by the sensor and relayed to a special integral valve.

This valve is coupled to the vehicle's brake pipes and acts as a normal relay valve when there is no danger of a skid. If a wheel lock is sensed, however, the valve fulfils its second .function, by pushing air to the other side of the modified brake diaphragm chambers to remove the braking effect and allowing

the wheel to turn.

The modifications to the brake chambers include new cast and sealed front covers replacing the existing pressed steel ones. All these actions take place quickly with a fast on-off cycle.

With the Dunlop system, anti-lock secondary braking may also be included by the addition of a small secondary valve, at very small extra ccist. Maxaret includes a warning system which consists of a telltale lamp mounted on the dash which monitors the system_ This light will glow as the ignition is turned on and the integral valve is run through its anti-skid operation. It also lights during braking when a wheel lock would occur — if the system is defective.

Although the Dunlop device was primarily designed for tractive wheels, and therefore is propshaft sensed, it is also available with wheel sensing. In this case the sensor ring is fitted to the inside of the brake drum, while the sensor transducer is attached to the stub axle.

It's a bone of contention which order the axles of an artic should be fItted with anti-lock braking. Dunlop maintains that its experience and testing over the last seven or eight years indicates that the order should be: first, tractive unit driven wheels; secondly, trailer axle wheels; and thirdly, steered axle of the tractive unit — but the latter only if the trailers used with the tractor also have anti-lock.

Potentially very dangerous trailer swing conditions can, says Dunlop, result if the driver is given -steerabilityof his vehicle unless the trailer wheels are "unlockable-.

To sum up, the Dunlop philosophy is that cornpatability of axle braking is essential. It's no good removing one dangerous situation to replace it with another.

There are now nearly 100 Maxaret distributors throughout the British Isles. Their workshop personnel regularly go to Dunlop for training, not only how to fit the system, but for details knowledge of its operatio Dunlop aims to provide complete sales and servis package with service back-L for every Maxaret sold. To da that number is fast approachir 4,000 axle units, each costir around £300 fitted, dependir on the type of vehicle.

The Dunlop propshaft sen ing allows Maxaret to be fitted more easily as a retrofit — that is after the vehicle has been built. And many operators specify it as original equipment when ordering the vehicle from a commercial vehicle dealer.

Girling was a fairly latecomer to the anti-lock market but is making up for lost time now. The sytem employed, Skidchek, is based on the American Kelsey-Hayes antilock device.

Lucas, Girling's parent company, has a reciprocal arrangement with Kelsey-Hayes on other electrical equipment, so it decided to adopt this system rather than develop its own at great expense, and with long delay.

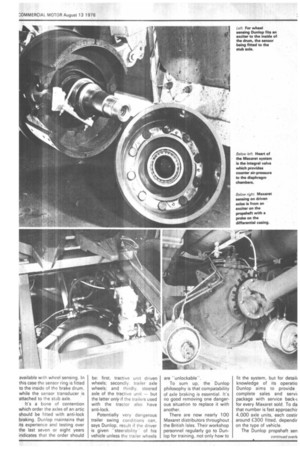

Skidchek is only wheel sensed. This means it can be fitted to any or all the vehicle's axles. Like the wheel-sensed Maxaret, Skidchek uses an exciter ring bolted to the drum with a pick-up on the hub. The two must be close together, so the pick-up is rubber mounted. This allows it to be pushed forward before the drum is refitted, then find its own position when the drum is slid on.

In use, when the exciter ring stops turning at the point the wheel stops, air is dumped quickly from the brake system having been commanded to by the sensor via a solenoid valve. When the wheel is turning again air is once more allowed back into the system. No effect is felt on the pedal, as the valve is situated down stream from the foot valve.

Should any malfunction in Skidchek occur, the brakes return to normal. Skidchek has now been developed for air over hydraulic systems too. Here an additional hydraulic de-boost valve is fitted which effectively traps fluid in the system, releasing pressure on the brakes with no effect on the pedal.

Girl ing' s anti-lock systemalso incorporates a safety warning system. A warning light shows when the ignition is turned on and the system runs through its sequence_ In the event of any failure during running, regardless of whether the brakes are applied, the light will come on.

Skidchek is being fitted by Volvo on export vehicles bound for the USA, and Ailsa Trucks offer it as an on-line option. Girling is setting up centres to fit the device nationwide. The system is currently being evaluated by both British Road Services and the Post Office.