Road Test of A 190 Dumptruk

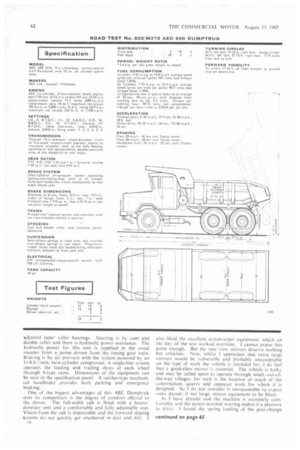

Page 62

Page 63

Page 64

Page 67

If you've noticed an error in this article please click here to report it so we can fix it.

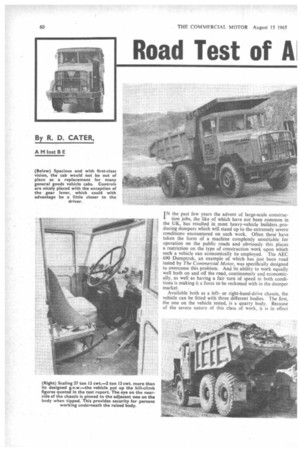

IN the past few years the advent of large-scale construe' tion jobs, the like of which have not been common in the UK, has resulted in most heavy-vehicle builders-producing dumpers which will stand up to the extremely severe conditions encountered on such work. Often these have taken the form of a machine completely unsuitable for operation on the public roads and obviously this places a restriction on the type of construction work upon which such a vehicle can economically be employed. The AEC 690 Dumptruk, an example of which has just been road tested by The Commercial Motor, was specifically designed to overcome this problem. And its ability to work equally well both on and off the road, continuously and economically, as well as having a fair turn of speed in both conditions is making it a force to be reckoned with in the dumper market.

Available both as a leftor right-hand-drive chassis, the vehicle can be fitted with three different bodies. The first, the one on the vehicle tested, is a quarry body. Because of the severe nature of this class of work, it is in effect Ily constructed version of se body, having the same oils. The use of heavierthroughout the construe. type makes it heavier by m, this being the reason Ad during the road test.

e of 10 cu. yd. struck .,tit of the general-purpose and the quarry body, third body type available Al carrying and in place n the dumper bodies, this tail gate: the cab protecds over only half the cab 3acity is 19-5 cu. yd. The ly is 1-78 tons.

he tipping gear used on ie Edbro Model IS DN n, three-stage unit giving maximum tipping angle

f 700. This is powered y a twelve-cylinder posive-displacement pump of le swash-plate type riven from a p.t.-o. iounted integrally on to le side of the gearbox. he control lever of the rting gear has four posions—lift, hold, power awn, and float; it operM a fast acting spooldye mounted inside the hydraulic oil reservoir, where it is nnpletely 'protected.

Only one engine is available in the 690—the AEC 2AV )0 six-cylinder diesel engine having a bore of 130 mm. .12 in.) and a stroke of 142 mm. (5.59 in.) which gives it capacity of 11-3 litres (690 Cu. in). The maximum net 3wer output of the unit is 182 b.h.p. at 2.000 r.p.m. and aximum net torque is 522 lb. ft. at 1,100 r.p.m. The drive taken through a hydraulically operated single dry-plate

clutch of 16 in. diameter to a five-speed. co stant-mesh gearbox to the double-reduction, spiralbevel/double helical rear axles which have a ratio of 9.04 to I. The fully articulated bogie is carried on two inverted semielliptic leaf springs mounted on a transversed cross shaft and is capable of accepting a maximum diago al displacement of 13 in.

A forged 1-section beam front axle is u d, having 2-563-in. dia. stub axles carrying hub assemblie on vernierc5 adjusted taper roller bearings. Steering is by cam and double roller and there is hydraulic power assistance. The hydraulic power for this unit is supplied in the usual manner from a pump driven from'the timing gear train. Braking is by air pressure with the system powered by an 11-8 ft.'/min. twin-cylinder compressor. A single-line system operates the leading and trailing shoes at each wheel through S-type cams. Dimensions of the equipment can be seen in the specification panel. A ratchet-type mechanical handbrake provides both parking and emergency braking.

One of the _biggest advantages of this AEC Dumptruk over its competitors is the degree of comfort offered to the driver. The full-width cab is fitted with a heater, demister unit and a comfortable and fully adjustable seat. Vision from the cab is impeccable and the forward sloping screens do not quickly get smothered in dust and dirt. I also liked the excellent screen-wiper equipment, which on the day of the test worked overtime. I cannot praise this point enough. But the rear view mirrors deserve nothing but criticism. Now, whilst I appreciate that extra large mirrors would be vulnerable and probablyunacceptable on the type of work the vehicle is intended for, I do feel that a good-class mirror is essential. The vehicle is bulky and may be called upon to operate through small, out-ofthe-way villages, for such is the location of much of the construction, quarry and opencast work for which it is designed. So I do not consider it unreasonable to expect some decent. if not large. mirror equipment to he fitted.

As I have already said the machine is extremely comfortable. and the power-assisted steering makes it a pleasure to drive. I found the spring loading of the gear-change

na bit on the heavy side when operating on the road I I do not altogether agree that the system of putting loading across fourth and fifth gears is the right thing lo Presumably because the vehicle is expected to use t and reverse more than any other gears these are left straightforward selection and, as I found to my cost. ; extremely simple to engage reverse whilst moving ford, should one be unfortunate enough to hit some rough und. This was an item that, taken from the engineer's It of view, 1 considered as potentially dangerous to the I-being of the gearbox.

Othough first introduced on September 1 , 1964. the C 690 Dumptruk only recently became available to Commercial Motor for testing. Because the vehicle lesigned to operate both on and off the highway, the was carried out partly in a limestone quarry and partly public roads.

lequate Braking

Vhen travelling to the area chosen to carry out the brake s it was necessary to traverse a long, Somerset downle through narrow, winding country lanes. As at that e the vehicle was grossing 24 tons the brakes came in some punishment and the result was that there was not ugh time to allow them to cool sufficiently to obtain y good braking figures. What the test did prove, howr, was that fade would not be a serious factor, because n though heated up considerably more than I would e liked to sec them for the job that 1 was doing, a )le series of maximum-pressure stops from both 20 and n.p.h. produced the same Tapley-meter reading 48 per t.

:ecause of very heavy rain I was unable to use the -king gun to check stopping distances, but the impresI got from the general performance of the brakes that they were adequate for the job they are required Jo. The air compressor also was well up to the job, zing up the depleted storage tank in double-quick time. : handbrake produced a Tapley meter reading of ier cent from 20 m.p.h.

op speed of the machine proved to be 34 m.p.h. and n checked in the gears the maximum speeds were: first. .p.h.; second. 12 m.p.h.: third. 19 m.p.h.; and fourth, a_p.h. Accelerating through the gears the machine luced figures of 21-4 sec. from 0 to 20 m.p.h., and sec. from 0 to 30 m.p.h. In direct drive it covered n 10 to 20 m.p.h. in 20 sec. and from 10 to 30 m.p.h. in cc. Fuel consumption runs. both ladgn and empty luced figures over a 10.2-mile stretch of firstand ind-class roads of 4.42 m.p.g. laden at an average speed 6.8 m.p.h., and empty over the same route, 7-75 m.p.g. 5.4 m.p.h.

hill-climb test was carried out in the quarry and for purpose the vehicle was loaded to the maximum that ld be got into the body. This proved to give a gross cle weight of 27 tons 13 cwt. and with this pay-load xis 13 cwt.—the vehicle performed adequately, climbing test hill, which was 0-6 mile long and has a maximum tient of 1 in 5 and an average gradient of 1 in 7.5. total time of 3 min. 48-25 sec. Out of this time. In. 58.5 sec. was spent in the lowest gear used (first) and lowest speed recorded was 5 m.p.h. Ambient temperaat the time of this test was 21'.0 (70"F) and the ne coolant at the start of the climb was 66'C (152'F). he end of the climb this had risen to 91:C (197°F).

mme idea of the capability of the machine when engaged uernal-site, short-haul operations can be seen from the >wing set of results, which were taken from a large iber of trips made from the quarry face to a crushing hine 0.2 miles away. This entailed climbing and ending a 1 in 5 gradient approximately 50 yd long on t the outward and inward journeys from the face and le face, reversing into position in front of the crusher. tipping. Loading was carried out by a Ruston-Bucvnis RB-38 digger equipped with a 1-5 Cu. yd. bucket. Filling the body with an average of 9-3 buckets per journey took an average of 4 min. 48 set. Laden haul-time averaged 1 min. 36 sec. and positioning time at the crusher 13 sec. Tipping time was 30 sec. and the unladen haul. averaged 1 min. 13 sec., whilst to spot the vehicle under the digger averaged 24 sec. Gross vehicle weight averaged 25 tons 18 cwt. and payload 14 tons 8 cwt.

With a total cycle time of 8 min. 44 sec., the fuel consumption per trip was I.89 pints—that is, 1.62 gal. per working hour. The output per working hour averaged 98-15 tons, and the fuel consumption per ton 0.0164 gal.

Operating at this level was not in any way punishing to the vehicle or the man driving it, and it will be seen that an eight-hour working day could easily see around 780 tons of limestone moved over this distance. It was very noticeable also that the suspension of the vehicle was completely adequate for the job it was builtto do, whilst on the road the ride was as good, if not quite a bit better, than a number of general goods vehicles. The extremely low axle ratios restrict the maximum -road speed. but once in the quarry give the vehicle that extra bit of push that is needed to makefast times in adverse conditions a sitnple proposition.

Being fitted with single wheels on the rear bogie gives the 690 two distinct advantages over twin-wheeled equipment. The first of these is that at no time during its life is it likely to pick up tyre-damaging rocks between its wheels; secondly. when it is operating on a job that entails covering public roads and muddy conditions on the sites, it will drag considerably less muck on to the highway. When a number of vehicles are working a job entailing short hauls of this nature, this last point-is of no small moment.

From the maintenance point of view the 690 appears very good indeed. Everything is simple to get at and apart from the normal complications found when working on engines, I could see nothing that would present a problem to a site fitter used to working under the adverse conditions that are his normal lot. It is true that the single inverted rear springs would prove a bit of a handful; but apart from this, components likely to need frequent attention are sensibly placed so as to be easy to get at. One thing I liked was the inclusion of a pin of very generous dimensions for locking the body when in the raised position with somebody working underneath.

Sole concessionnaires in the UK for AEC Dumptruk models are Scottish Land Development Ltd., which has live sales and service denots around the country and is backed by excellent AEC service organization providing 24-hour 365-days-a-year coverage for all requirements.