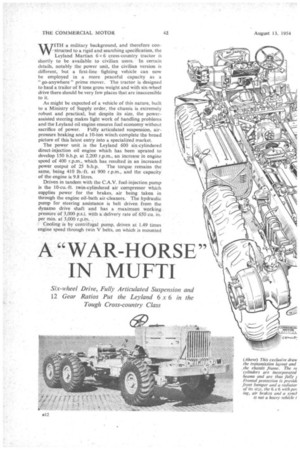

A "WAR-HORSE" IN MUFTI

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

Six-wheel Drive, Fully Articulated Suspension and 12 Gear Ratios Put the Leyland 6 x 6 in the Tough Cross-country Class W1TH a military background, and therefore con-structed to a rigid and searching specification, the Leyland Martian 6 x 6 cross-country tractor is shortly to be available to civilian users. In certain details, notably the power unit, the civilian version is different, but a first-line fighting vehicle can now be employed in a more peaceful capacity as a " go-anywhere " prime mover. The tractor is designed to haul a trailer of 8 tons gross weight and with six-wheel drive there should be very few places that are inaccessible to it.

As might be expected of a vehicle of this nature, built to a Ministry of Supply order, the chassis is extremely robust and practical, but despite its size, the powerassisted steering makes light work of handling problems and the Leyland oil engine ensures fuel economy without

sacrifice of power. Fully articulated suspension, airpressure braking and a 10-ton winch complete the broad picture of this latest entry into a specialized market.

The power unit is the Leyland 600 six-cylindered direct-injection oil engine which has been uprated to develop 150 b.h.p. at 2,200 r.p.m., an increase in engine speed of 400 r.p.m., which has resulted in an increased. power output of 25 b.h.p. The torque remains the same, being 410 lb.-ft. at 900 r.p.m., and the capacity of the engine is 9.8 litres.

Driven in tandem with the C.A.V. fuel-injection pump is the 10-cu.-ft. twin-cylindered air compressor which supplies power for the brakes, air being taken in through the engine oil-bath air-cleaners. The hydraulic pump for steering assistance is belt driven from the dynamo drive shaft and has a maximum working pressure of 3,000 p.s.i. with a delivery rate of 650 cu in per min. at 3,000 r.p.m. .

Cooling is by centrifugal pump, driven at 1.49 times engine speed .through twin V belts, on which is mounted the six-bladed 19+-in.-diameter fan. An eight-row pressurized radiator of the Morris H type matrix has a relief valve set to operate at 10 p.s.i. above atmospheric pressure and the system is controlled by a thermostat, fully opened at 90° C.

Mounted' as a unit with the engine is the four-speed main gearbox, with synchromesh engagement of second, third and top gears. The ratios are 5.0, 2.63, 139 and 1 to 1, with a reverse gear of 6.15 to 1. A single-dryplate clutch of 161-in, diameter has a flexible centre plate and is ventilated by holes in the flywheel. Fourpoint mounting is used for the engine and gearbox unit, with flexible links attached to the front of the cylinder block and tubular rubbers bolted to brackets from the clutch housing at the rear. A short cardan shaft takes the drive from the main gearbox back to the three-speed auxiliary box, this having constant-mesh gears. The box provides two step-up ratios of 1.59 and 1.23 to 1 and a reduction ratio of 1.597 to 1, and incorporates the front-wheel-drive engagement gearing and the power take-off for the winch drive. An interlocking arrangement allows the auxiliary box low ratio to be engaged only when six-wheel-drive is in use.

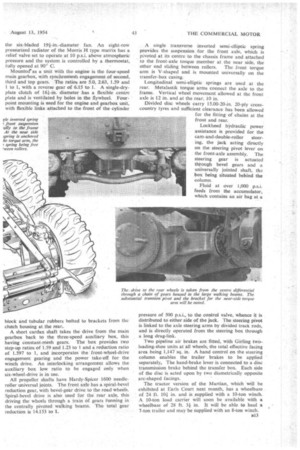

All propeller shafts have Hardy-Spicer 1600 needleroller universal joints. The front axle has a spiral-bevel reduction gear, with bevel-gear drive to the road wheels. Spiral-bevel drive is also used for the rear axle, this driving the wheels through a train of gears funning in the centrally pivoted walking beams. The total gear reduction is 14.153 to 1. A single transverse inverted semi-elliptic spring provides the suspension for the front axle, which is pivoted at its centre to the chassis frame and attached to the front-axle torque member at the near side, the other end sliding between rollers. The front torque arm is V-shaped and is mounted universally on the t ransferbox easing.

Longitudinal semi-elliptic springs are used at the rear. Metalastik torque arms connect the axle to the frame. Vertical wheel movement allowed at the front axle is 12 in. and at the rear, 10 in.

Divided disc wheels carry 15.00-20-in. 20-ply crosscountry tyres and sufficient clearance has been allowed for the fitting of chains at the front and rear.

Lockheed hYdraulic power assistance is provided for the cam-and-doubleroller steering, the jack acting directly on the steering pivot lever on the front-axle assembly. The steering gear is actuated through bevel gears and a universally jointed shaft, the box being situated behind the column.

Fluid at over 1,000 p.s.i. feeds from the accumulator, which contains an air bag at a pressure of 500 p.s.i., to the control valve, whence it is distributed to either side of the jack. The steering pivot is linked to the axle steering arms by divided track rods, and is directly operated from the steering box through a long drag-link.

Two pipeline air brakes are fitted, with Girling twoleading-shoe units at all wheels, the total effective facing area being 1,147 sq..in. A hand control on the steering column enables the trailer brakes to be applied separately. The hand-brake lever is connected to a disc transmission brake behind the transfer box. Each side of the disc is acted upon by two diametrically opposite arc-shaped facings.

The tractor version of the Martian, which will be exhibited at Earls Court next month, has a wheelbase . of 24 ft. 101 in. and is supplied with a 10-ton winch. A 10-ton load carrier will soon be available with a wheelbase of 28 ft. 3+ in. It will be able to haul a 7-ton trailer and may be supplied with an 8-ton winch.