Dodge Enters the 7-ton Class

Page 51

If you've noticed an error in this article please click here to report it so we can fix it.

Dodge 7-tonner is a Largescale Version of the Present Range, to be Available with Petrol or Oil Engine

A 7 TON semi forward control 1—X chassis, to be shown at Earls Court with a 4.3-litre petrol engine, has be..n added to the Dodge range of goods chassis and an alternative oil engine, a It° b.h.p. unit, is to follow.

It is a 14-ft. 34-in.-wheelbase model with a long-stroke engine, five-speed gearbox and hypoid axle. A Clayton Dewandre servo operates the Girling

hydraulic braking system. The Lstimated unladen weight of the petrolengined version, with a platform body, is 3 tons 4 cwt.At present the petrolengined chassis, to be exhibited with left-hand drive, is available only for export.

Long Stroke

The 4.3-litre engine has a common bore size with other Dodge sixcylindered units, but the 4.1-in. stroke is .longer than in the 5-tonners nd 6-tonners. The external dimensions of the engines and location of the components are similar to those of existing models. An It-in.diameter clutch and five-speed constant mesh direct-drive-top gearbox are attached as a unit, and there are two standard power-take-off mounting points on the sides of the box.

A two-piece propeller shaft, having a self-aligning doublerow centre bearing, is used in the transmission to the hypoiddrive fully floating axle. The standard ratio for the 7-ton long-wheelbase chassis is 6.66 to 1.

Heavy-duty., brake gear is specified for, this' model, which includes a Clayton. Dewandre 175-mm. vacuum servo motor and Girling hydraulically, operated two-leading-shoe units, Dual cylinders are provided at the front wheels, whilst at the rear high-centre-lift shoes are employed. With a total frictional area of 470 sq. ins., the front drums are 16 ins, in diameter and 3 ins, wide, and those at the rear are 151 ins. in

diameter, with 4i-in.-wide shoes and moulded facings.

The frame is a standard 8i-in. by 3-in. channel-section unit, but with an L-shaped reinforcement, 910-6 ins, deep and having 2-in.-wide flanges between the axles. Channel-section crossmembers are employed, but the A bracing behind the gearbox in the existing Dodge chassis is replaced by an additional member behind the cab. The longitudinals are level on the top flanges from the rear to the cab, but are sloped down at the front and extended beyond the spring brackets to enable the bumper bar to be rigidly attached.

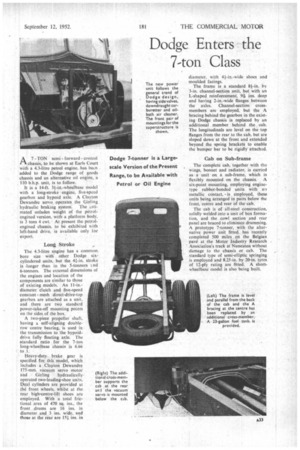

Cab on Sub-frame The complete cab, together with the wings, bonnet and radiator, is carried as a unit on a sub-frame, which is flexibly mounted on the chassis. A six-point mounting, employing enginetype rubber-bonded units with no metallic contact, is employed, these units being arranged in pairs below the front, centre and rear of the cab.

The cab is of all-steel construction, solidly welded into a unit of box formation, and the cowl section and rear panel are braced to eliminate drumming. A prototype 7-tonner, with the alternative power unit fitted, has recently completed 500 miles on the Belgian pavd at the Motor Industry Research Association's track at Nuneaton without damage to the chassis or cab. The standard type of semi-elliptic springing is employed and 8.25-in. by 20-in. tyres of I2-ply rating are fitted. A shortwheelbase model is also being built.