Designing Bus Bodies for the Tropics

Page 36

Page 37

Page 38

If you've noticed an error in this article please click here to report it so we can fix it.

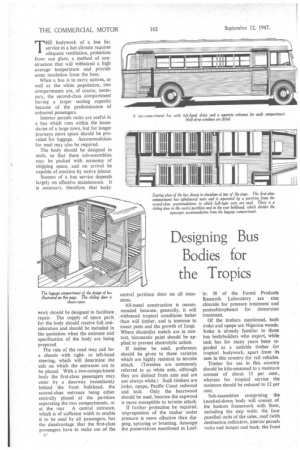

THE bodywork of a bus for service in a hot climate requires adequate ventilation, protection from sun glare, a method of construction that will withstand a high average temperature and provide some insulation from the heat.

When a bus is to carry natives, as well as the white population, two compartments are, of course, necessary, the second-class compartment having a larger seating capacity because of the predominance of coloured passengers.

Interior parcels racks are useful in a bus which runs within the boundaries of a large town, but for longer journeys more space should be provided for luggage. Accommodation for mail may also be required.

The body should be designed in units, so that these sub-assemblies may be packed with economy of shipping space, and on arrival be capable of erection by native labour.

Success of a bus service depends largely on effective maintenance. It is necessary, therefore, that body work should be designed to facilitate repair. The supply of spare parts for the body should receive full, consideration and should be included in the quotation when the estimate and specification of the body are being prepared.

The rule of the road may call for a chassis with rightor left-hand steering, which will determine the side on which the entrances are to be placed. With a two-compartment body the first-class passengers may enter by a doorway, immediately behind the front bulkhead, the second-class entrance being either centrally placed at the partition separating the two compartments, or at the rear A central entrance, which is of sufficient width to enable it to be used by all passengers, has the disadvantage that the first-class passengers have to make use of the

a'

central partition door on all occasions. • All-metal construction is recommended because, generally, it will withstand tropical conditions better than will timber, and is immune to insect pests and the growth of fungi. Where dissimilar metals are in contact, bitumastic paint should be applied to prevent electrolytic action.

If timber be used, preference should be given to those varieties which are highly resistant to termite attack. (Termites are commonly referred to as white ants, although they are distinct from ants and are not always white.) Such timbers are iroko, opepe, Pacific Coast redwood and teak. Only the heartwood should be used, because the sapwood is more susceptible to termite attack

If further protection be required, impregnation of the timber under pressure is more effective than dipping, spraying or brushing. Amongst the preservatives mentioned in Leaf

le: 38 of the Forest Products Research Laboratory are zinc chloride for pressure treatment and pentachlorphenol for immersion treatment.

Of the timbers mentioned, both iroko and opepe are Nigerian woods. Iroko is already familiar to those bus bodybuilders who export, while teak has for many years been regarded as a suitable timber for tropical bodywork, apart from its uses in this country for rail vehicles.

Timber for use in this country should be kiln-seasoned to a moisture content of about 15 per cent., whereas for tropical service the moisture should be reduced to 12 per cent.

Sub-assemblies comprising the knocked-down body will consist of the bottom framework with floor, including the step wells; the four panelled units of the sides, roof (with destination indicators, interior parcels racks and lamps) and back; the front bulkhead, cab sides and windscreen, with cab door; entrance and emer. gency doors, also the partition complete with door. Seating should be nested as far as possible, with cushions and squabs, designed for easy attachment, packed separately.

Although a moderately curved design of body is usually preferred, an angular design is simpler to construct and assemble, and it has more interior air space. The sub-assemblies take up less room in pecking. A partial return to angular outlines is noticeable in private car design, and in due course it may become fashionable for public service vehicles.

As the first-class compartment is in front and well forward of the rear wheel-arches, all seats face forwards, with an entrance at the front bulkhead, and the emergency door, for use by all passengers, opposite to it.

The native compartment will have lengthwise seats over the rear wheelarches, the other seats facing forwards. The actual arrangement of the seats will depend on the position of the entrance and on whether any space in this part of the saloon be set apart for luggage.

All the seats in the second-class compartment may face forwards if the floor• be raised so as to reduce sufficiently the projection of the wheel-arches. The floor may be raised by means of a step at the base of the partition which separates the two compartments.

Frames of all seats may be of tubular construction. The first-class seats arc upholstered and the secondclass ones ha-ye wood slats. Most overseas regulations will allow the body to be 8 ft. wide overall, so that the facing-forward seats may be 3 ft. long.

The entrance doors may be hung at the top of the steps and open outwards, or arranged to slide either inside or outside the body. An outside sliding door encroaches less on the overall width of the body than a door which slides inside. A sliding door for the partition is to be pre ferred, because it causes less obstruction when in use.

As already indicated, ventilation is important. Thp ventilating scheme should include a double roof constructed to allow a stream of air to enter freely at the front peak and flow throughout the length of the vehicle between the outer and inner roof panels, with means for exit at the rear.

Heated air is removed from the interior of the body by means of extractors fitted in the roof, and there should be Some form of permanent ventilation, such as an opening 2 ins. or 3 ins, deep between the cant rail and the tops of the windows. This opening may be fitted with

louvres, but all such openings should have inside wire mesh guards_ to exclude dust.

For ventilation of the driver's 'cab. there will be a large air extractor in the roof, as well as the hinged upper panel of the windscreen, and sliding windows on each side. _Apart from the air currents passing between the outer and inner roof panels, the cab should have an independent ventilating scheme, and no air currents originating in the cab should be allowed to pass into the saloon.

This need not preclude the fitting of a drop or sliding window in the front bulkhead for purposes of communication. An electric fan in the front bulkhead, or in the partition, may be fitted to promote air circulation, which will be of particular value when the vehicle is stationary. If there be sufficient space, fans may be mounted horizontally between the outer and inner roof panels.

The degree of insulation which the shell of the bodywork affords prevents any undue rise of temperature in the bus. The roof is insulated by the air layer between the double panelling, and the double-panelled sides and back of the body may have a packing of lightweight insulating material inserted.

If half-drop windows be provided, the insulating medium may extend from the waist to the bottom of the body. Windows should be fitted with spring roller blinds. to prevent sun glare, the material being of not too close a weave, so that some air may pass through it. A sun blind is more effective if it can be mounted outside, rather than inside, the window; but this would appear to be impracticable for a public-service vehicle.

Apart from lengthwise parcel racks at the sides of the body above the seats, an enclosed space may be provided on one side of the secondclass compartment, next to the partition, with access from inside or outside, or both positions. The luggage compartment may be at the rear, extending the full height of the body, and fitted with shelves, or a smaller locker may be built under the back seat, so that there is no loss of seating capacity.

Luggage carried on the roof may be reached by means of a ladder. Bicycles are frequently used for travelling to the bus stop and for completing the journey after leaving the bus. These may be carried on the roof, secured to rails. If there be restricted headroom in the garage, cycle rails may be hinged so as tocollapse.

Bodywork spares for shipping with, or shortly after, the vehicles may include window and door fittings, with all necessary bolts, screws and other fastenings, glass cut t size, glass channels and glazing strip, step treads, lengths of moulding, cornice and water guttering, upholstery materials, including blinds on rollers, seat laths, inside fillets and the wire mesh or other guards fitted to ventilators.