From Drivers and Mechanics.

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best communication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

When the Thread Strips.

[1113] ".J.R." (Gateshead-on-Tyne) writes After overhauling the engine on our 20 h.p. van, we were just preparing to go out one afternoon, when we happened on a couple of holes in the top of the waterjacket and on the water-pipe joint, which were almost completely stripped of the thread. When the engine was running, the pump drove the water out between the flanges and the jacket. As is usual in such cases, there was not a tap in the place which would allow us to tap out the hole again. We managed in the following way.

"A wedge-shaped slot was cut in the bottom of the bolts, and a small iron, wedge was filed up to fit into this slot. It was then driven in until the bolt was expanded about 1-64 in. This enabled the bolt to obtain sufficient grip to let us screw it down to the bottom of the tapped hole. The wedge, which projected about * in. from the bottom of the bolt, then bound on the bottom of the hole, and the more we tightened the bolt, the more the wedge jammed up and increased the diameter. We sawed off the head of the bolt and screwed the projecting end, and then locked it tightly with a nut and washer, and filed the head in order to remove the ragged edges. The job is still holding, and we have had no further trouble. A great deal of expense is caused in workshops by the men not paying enough attention to the matter of good screw-threads. Many men tap out a hole, and drive a bolt down without blowing out the chips. Then the bolt tears when it is taken out, and the work has to be done again."

A Useful Marking-off Tool.

[1114] " W.B." (Finsbury) writes The following simple tool was described in a recent issue of 'The American Machinist,' which is, I daresay, familiar

to you although it may not be to your drivermechanic readers. I thought the tip was useful, so I cut it out and am forwarding the cutting to you. Perhaps you may care to bring it to the notice of your readers. [We have pleasure in doing 50.—ED.]

"The object of the device is to obviate loss of time through looking for pieces of wood, leather, tin, etc., in order to pack up a hole when feeling for the centre of a flange. The tool is used in the following way. The small trammel bar with scriber attached is shown in the sketch vertical to the work. The scriber should be turned at a slight angle to the work, and if this is done it will mark much more smoothly. The required dimensions should first be marked off, and the overall distance checked. The tool can then be set, and the required lines scribed."

Wedging the Piston.

The sender of the following communication has been awarded the 108. prize this week.

[1115] " F.E.D." (Poplar) writes :—" The following particulars, showing the way in which I overcame a little breakdown on my wagon, may be of interest to some of your readers. One afternoon during last summer I was about 14 miles from home when one .of the gland-studs on the low-pressure piston broke off short. This was not due to not having split pins in position, as I always take particular care to see that these are in place wherever they are necessary. The net result of the breakage was that all the packing blew out of the gland. To effect a. proper repair there and then would have meant taking one side of the engine almost to pieces, and even if this had been done I had no tools with me to get out the broken stud. The wagon, fortunately, was unloaded, and so I took off the connecting-rod and crosshead, and also the cylinder cover, and then I pushed the piston to the front of the cylinder and noted the distance from the back of the piston to the cylinder cover. I then obtained a piece of wood, and cut it to this length, and placed it between the cylinder cover and the piston. I then replaced the gland-cover, and was enabled to steam away, using only one cylinder.

"I have often seen simple little breakages hold up inexperienced drivers, who have had to sit tight on the broken-down wagon until a telephone message or a wire brought assistance. I think there ought to be some kind of a test for steam and petrol-wagon drivers, somewhat similar to the test for drivers instituted by the R.A.C. This should be done before any man is granted a licence, and I think that some such little examination in theory and practice would lead to a great improvement in the average wagon driver. There are so many on the road now who are given charge of a valuable van or wagon, who can only just start and stop a vehicle, and when the engine jibs because the slide is shifted slightly, or some other trifling thing happens, they are held up." Improving the Pump Leather.

[1116] " X " (Cardiff) writes The following little suggestion may help my fellow readers who have experienced trouble at some time or other with pressure or tire pumps in which the plunger is a cupped leather. It very often happens that there is

waste motion in the pump plunger owing to the leather cup not expanding until sufficient pressure has been raised in the pump to press the leather against the walls of the barrel. To obviate this trouble, one coil of a. steel or brass wire spring should be placed inside the leather cup, and one end of this spring should be bent inwards so as to act as a split pin, and also to prevent the spring from coming out of the pressure cup. The sketch [We have had this re-drawn.---En.] will illustrate my meaning, I think, quite plainly."

Advice to the Taxi-driver.

[1117] " C.B." (Hornsey Rise) writes Warping

and twisting of loose boards or footboards, caused through the wood not being properly matured, and which warping is often assisted by the warmth of the engine and the draught of the flywheel, can be easily avoided, and the boards strengthened by the fixing of a couple of lengths of angle or tee-iron to act as battens. When teak footboards are wet they become dangerous, for this wood takes on a soapy and slimy surface ; the grain rises up and is full of splinters, and many accidents have occurred through this property of the wood and the warping which follows. The battens placed underneath do a great deal to prevent this.

"When painting or touching up damaged aluminium or lead-coated iron, such as panels, wings, etc., these parts should be scraped and given a thin coat of gold size. This prevents the paint from peeling and falling off."

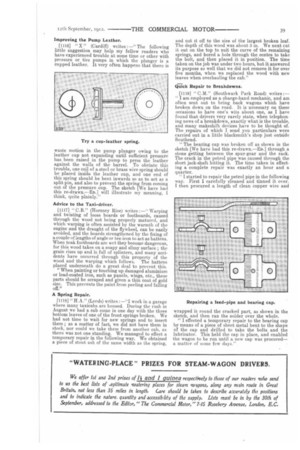

A Spring Repair.

11118] " HA." (Leeds) writes :—"I work in a garage where many taxicabs are housed. During the rush in August we had a cab come in one day with the three bottom leaves of one of the front springs broken. We had not time to wait for new springs and to insert them ; as a matter of fact., we did not have them in stock, nor could we take them from another cab, as there was not one standing. We managed to effect a temporary repair in the following way. We obtained a piece of stout. ash of the same width as the spring, and cut it off to the size of the largest broken leaf. The depth of this wood was about 3 in. We next cut it out on the top to suit the curve of the remaining springs, and bored a hole through the centre to take the bolt, and then placed it in position. The time taken on the job was under two hours, but it answered its purpose so well that we did not remove it for over five months, when we replaced the wood with new leaves when overhauling the cab."

Quick Repair to Breakdowns.

[1119] " C. M." (Southwark Park Road)writes:— "I am employed as a charge-hand mechanic, and am often sent out to bring back wagons which have broken down on the road. It is necessary on these occasions to have one's wits about one, as I have found that drivers very rarely state, when telephoning news of a breakdown, exactly what is the trouble, and many makeshift devices have to be thought of. The repairs of which I send you particulars were carried out in a little blacksmith's shop just outside Southend.

"The bearing cap was broken off as shown in the sketch [We have had this re-drawn.—En.] through a stone getting between the spur-gear and the rack. The crack in the petrol pipe was caused through the short jack-shaft hitting it. The time taken in effecting a complete repair was exactly an hour and a quarter. "I started to repair the petrol pipe in the following way. First I carefully cleaned and tinned it over. I then procured a length of clean copper wire and wrapped it round the cracked part, as shown in the sketch, and then ran the solder over the whole. "I effected a temporary repair to the bearing cap by means of a piece of sheet metal bent to the shape of the cap and drilled to take the bolts and the lubricator. This held the cap in place, and enabled the wagon to be run until a new cap was procured— a matter of some few day:,.."