How to Keep Your Lorry Fit. VIII.

Page 5

Page 6

Page 7

If you've noticed an error in this article please click here to report it so we can fix it.

The Deservedly-popular Foden Steam Wagon Forms the Subject of Our Eighth Article.

The Foden company points out. in the introductory remarks to its instruction book that a driver should have moderate ideas of speed. With a steel-tired wagon he should not exceed five miles per hour on good roads, and on uneven rough roads four miles per hour should be the limit. Not only does excessive speed put an undue strain on the framing, wheels and other mechanism, but it also calls upon the engine to revolve at a high speed, thus shortening the life of th's essential component. On rubber tires the damage from this cause is less, and speeds up to 8 m.p.h. are permissible. It is pointed out i that the engine fitted n the Foden wagon is a powerful one ; it is not, however, intended to work at its full limit all the time. Its strength should he husbanded and used to the fullest extent only when mounting heavy gradients and for emergencies.

Use the Engine as a Compound

Only.

In the ordinary way, the engine works as a compound ; that is to say, the steam passes from the boiler to the high-pressure cylinder, there doing work and expanding, emerging thence and proceeding to the low-pressure cylinder, where it expands still further and performs more useful work. It leaves the low-pressure cylinder at a little greater than atmospheric pressure and finds its way up the chimney. This method of working is the normal one. For special purposes, however, when coupling up and getting over soft and greasy ground, or in the case where a very strong pull is needed for a short distance, additional power is available by working the engine as a double-highpressure one. In this case both cylinders receive fresh steam from the boiler and exhaust separately into the funnel. It will be gathered, if regard be had to the size of the low-pressure cylinder as compared with the high, that the effect of putting high-pressure steam on to both pistons must considerably increase the available power.

When Changing to High Pressure.

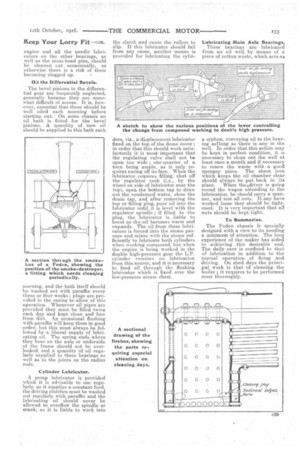

In order to change from compound to high pressure, and vice versa, a special hand lever is provided which controls the three-way cock at the bottom of the cylinder. In the ordinary way, for use as a compound, this lever is pushed away from the driver, and the loose peg,is put in the hole of the quadrant nearer the footplate. For working as a double high pressure, this lever should be pulled towards the driver, and so also should the starting handle. The peg in this case will be in the hole further from the footplate.

Using Either Engine Separately.

If the peg is placed in the hole nearer the footplate with the side lever pulled towards the driver, when steam is turned on it will enter the small or high-pressure cylinder only ; on the other hand, if the peg is-in the ,hole further from the footplate and the side lever at the same time pushed from the driver, this will allow steam to enter the large or low-pressure cylinder only. It is thus possible to work either engine separately in case of accident to one of them. In such an event, of course, it would be necassary,ito uncouple the connecting rod and link motion and set the valve spindle of the engine that was disabled in its mid position.

Pack the Glands.

It is essential that the gland of this three-way cock should be packed tightly, so that the lever can only just be pulled over ; if this is not the case, there will be a tendency for steam to blow up the chimney, wasting fuel and detracting from the available engine power.

Firing.

When on the road, perhaps the firing of the boiler is the most im portant item. If, however, the tubes be kept clean by being swept twice a day and the firebars kept free from clinkers, the labour consequent upon attending to this do. partment will be considerably reduced. It is a ,mistake to-poke the fire in order to make steam. Fresh fuel should be put on where the firebars are bare and the fire-doors should be opened as seldom as possible. Leaky tubes and damage tc firebox are caused owing to the firedoors being left open as a means of checking the steam-raising.

Damper Open in Cold Weather.

In cold, damp, or wintry weather, it is advisable always to keep the damper wide open during the period in which the engine is working ; th;s being the case,. it is necessary to effect the steaming of the boiler by firing lightly or heavily according to the load and road condition. Additional draught may be obtaMed by opening the fire-hole door about 14 in. ; this small opening will do no harm to the tubes, as in such a case the air is driven on to the fire, the door having been specially constructed so as to allow of this procedure.

Attention to Chain.

Whenever it is necessary to tighten the driving chain, the greatest care must be taken to adjust both radius rods equally To ascertain that this is done correctly, measure the distance between the centre of the radius pin and the lock-nut on each side ; the distances should be alike. It is advisable to wash the chain in paraffin oil at least once a week • it should be repeatedly lubrieate:d • furthermore, occasionally it should be removed and after being well cleaned with paran, immersed in a bath of lubricating oil and left there for two or three days. This prolonged immersion has the effect of allowing the oil to penetrate through the joints and lubricate the inner parts. The provision of a spare chain for alternate use will not only facilitate the needful periodical cleaning, but will prove, m m the long run, to be a substantial and real economy. Clean the Exhaust Pipe.

On cleaning days, in addition to the usual attention, it is necessary that the exhaust pipe from the lowpressure cylinder should be examined. This requires cleaning

about every two or three months, blast from a compound engine being comparatively soft allows the oil to bake on to the inside and gradually choke the orifice, the effect of which-is to increase the back pressure in the L.P. cylinder.

When Cleaning the Boiler.

The boiler itself should be cleaned out at least once a fortnight ; oftener if dirty water has been used. The three mud plugs at the bottom of the firebox should be taken out

and plenty of clean water run through the filling plug in the dome cover ; whilst the water is running through, the thin scraper should be freely used all round the bottom of the firebox, through the mud plugs,

and particularly at the back of the fire-hole door, where most of the dirt settles. It is important that the boiler should be allowed to become quite cold before commencing to wash ; if water be passed through the cylinders whilst they are hot they will crack.

The Steam Destroyer.

The steam destroyer in the smokebox into which the steam exhausts is placed there for the purpose. of superheating the steam and causing it to be invisible. It will be necessary to keep this box clean or it will not perform its work properly.

In frosty weather, the pipe from the tank to the injector should be removed each evening, otherwise there is a risk of its freezing and splitting. Week-ends are the most likely times for this to occur. In very severe weather it is advisable always to keep a fire in the boiler, and so obviate the risk of possible trouble from this cause.

Lubrication.

With regard to lubrication, the Poden company recommends good oil and plenty of it. Good cylinder oil should be used on all bearings that are near the boiler and subject to radiated heat. The stud shaft which carries the small sprocket wheel and two large spurs, is provided with a syphon lubricator on each end. It is important that these should feed freely, and to attain this they should be washed through with paraffin oil in the same manner as the main axle oilers. The other syphon lubricators on the engine and all the needle lubricators on the other bearings, as well as the cross-head pins, should be cleaned out occasionally, as otherwise there is a risk of them becoming clogged up.

Oil the Differential Bevels.

The bevel pinions in the differential gear are frequently neglected, generally because they are somewhat difficult of access. It is,-however, essential that these should be well oiled each morning before starting out. On some chassis an oil bath is fitted for the bevel pinions. A quantity of new oil should be supplied to this bath each morning, and the bath itself should be washed out with paraffin every three or four weeks ; plugs are provided in the casing to allow of this operation. Whenever oil pipes are provided they must be filled twice each day and kept clean and free from dirt. An occasional flushing with paraffin will keep them in good order, but this must always be followed by a liberal supply of lubricating oil. The spring ends where they bear on the axle or underside of the frame should not be overlooked, and a quantity of oil regularly supplied to these bearings as well as to the joints on the radius rods.

Cylinder Lubricator.

A pump lubricator is provided which it is advisable to use regularly. as it supplies a constant feed, the driving clutches must be washed out regularly with paraffin and the lubricating oil should never be allowed to overflow the spindleor crank, as it is liable to work into

the clutch and cause the rollers to slip. If this lubricator should fail from any cause, another means is provided for lubricating the cylin

ders, viz., a displacement lubricator fixed on the top of the dome cover ; in order that this should work satisfactorily it is most important that the regulating valve shall not be open too wide ; one-quarter of a turn being ample, as it only requires easing off •its face. When the lubricator, requires filling, shut off the regulator cock (i.e., by the wheel on side of lubricator near the top), open the boktom tap to draw out the condensed water, close the drain tap, and after removing the top or filling plug, pour oil into the lubricator until it is level with the regulator spindle ; if filled to the plug, the lubricator is .liable to burst as the .oil becomes warm and expands. The oil from these lubrieators is forced into the steam passage and mixes with the steam sufficiently to lubricate both cylinders when working compound, hut when the engine is being worked in the double high-pressure gear the L.P. cylinder receives no lubrication from this source, and it is necessary to feed oil through the flushing lubricator which is fixed over the low-pressure steam chest. Lubricating Main Axle Bearingst These bearings are lubricated from an oil well by means of a piece of cotton waste, which acts as

a syphon, conveying oil to the bearing astIong as there is any in the well. In order that this action may be kept in perfect condition, it is • necessary to clean out the well at least once a month and if necessary to renew the waste with a good spongey piece. The sheet iron which keeps the oil chamber clear should always be put back in its

place When the kdriver is going round the wagon attending to the lubrication, he should carry a spanner. and test all nuts, If. any have worked loose they should be tightened. It is very important that all nuts should be kept tights To Summarize.

The Foden chassis is specially designed with a view to its needing a minimum of attention. The long experience of the maker has aided in achieving this desirable end. The daily care is confined to that of lubrication in addition to the normal operation of firing and driving. On shed days the principal work is that of cleaning the boiler ; it requires to be performed most thoroughly.