The Equipment and Organisation of a Motor Repair Shop or Running Shed.

Page 16

Page 17

If you've noticed an error in this article please click here to report it so we can fix it.

FOURTH ARTICLE.

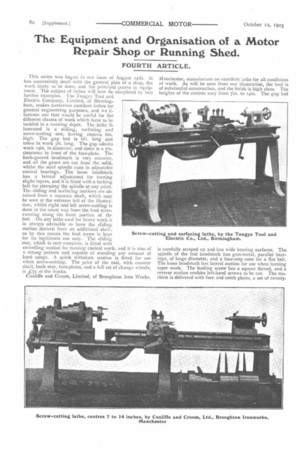

This series was begun in our issue of August 24th. It has successively dealt with the general plan of a shop, the work likely to be done, and the principal points in equipment. The subject of lathes will now be completed by two further examples. The Tangye Tool and

Electric Company, Limited, of Birmingham, makes numerous excellent lathes for general engineering purposes, and we illustrate one that would be useful for the different classes of work which have to be tackled in a running depot. The lathe itlustrated is a sliding, surfacing and screw-cutting one, having centres 6in. high. The gap bed is oft. long and takes in work 3ft. long. The gap admits work i9in. in diameter, and there is a 7in. clearance in front of the face-plate. The back-geared headstock is very massive, and all the gears are cut from the solid, whilst the steel spindle runs in adjustable conical bearings. The loose headstock has a lateral adjustment for turning slight tapers, and it is fitted with a locking bolt for clamping the spindle at any point. The sliding and surfacing motions are obtained from a separate shaft, which may be seen at the extreme left of the illustration, whilst right and left screw-cutting is done in the usual way from the lead screw running along the front portion of the bed. On any lathe used for heavy work it is always advisable to have the sliding motion derived from an additional shaft, as by this means the lead screw is kept for its legitimate use only. The sliding rest, which is very complete, is fitted with swivelling motion for turning conical work, and it is also of a strong pattern and capable of standing any amount of hard usage. A quick withdraw motion is fitted for use when screw-cutting, The price of the tool, with counter shaft, back stay, face-plates, and a full set of change wheels, is 4;72 at the works.

Cunliffe and Croom, Limited, of Broughton Iron Works,

Manchester, manufacture an excellent lathe for all conditions of work. As will be seen from our illustration, the tool is of substantial construction, and the finish is high class. The heights of the centres vary from 7in. to /4in. The gap bed is carefully scraped up and has wide bearing surfaces. The spjndle of the fast headstock has gun-metal, parallel bearings, of large diameter, and a four-step cone for a flat belt. The loose headstock has lateral motion for use when turning taper work. The leading screw has a square thread, and a reverse motion enables left-hand screws to be cut. The machine is delivered with face and catch plates, a set of twenty two change wheels and a set of spanners. The price of an Sin. machine with gap bed is £84 ins., and the approximate gross weight is about 32cwt. The price of the 6in. tool with gap bed is L57 18s. Drilling machines are, next to lathes, the most important tools in a repairing shop, hence, when a machine of this description is purchased, it is necessary to pay regard to the work which it will be called upon to do. Two drilling machines are really required. The first can be a light, handy machine for general small work, whilst the second should be one capable of dealing with comparatively heavy jobs. We propose to describe the lighter machines first.

The Britannia Engineering Company, Limited, of Colchester, makes some serviceable machines of both the heavy and light types, and we give particulars of their numbers 5 and 17. The former is intended for light work, and it drills holes up to fin. in diameter by sin, deep. The machine can be driven either by foot motion or power ; each style is useful for many purposes. Jr is constructed with the upper part of the body to swivel round a circular pillar, and it can be secured in any position by one nut; this will be found a very practical feature when large pieces are being handled. The pillar and the foot are one casting, the latter having lugs with holes bored through them, this provision enabling it to be bolted to a bench. A bracket, which swivels round the main pillar, carries a circular work-plate, which turns on its centre and thus gives every facility for adjusting any material which has to be operated upon. The feed is self-acting. The principal dimensions are as follows :

ain. in diameter by sun, high; diameter of circular work table, loin.; extreme distance between the nose of spindle when at its highest point and the top of the work iable, adin. ; diameter of spindle Tiin. The price of the tool

complete is j;io. If necessary, cast-iron gear covers can be supplied to conform with the requireMents of the Factory Acts as regards protection for the operatives. Brown Brothers, Limited, of Great Eastern Street, London, E.C., cater for the requirements of machine users interested in the motor movement. We reproduce a photograph of a small drill for holes up to, and including, din. in diameter. The power is transmitted by a belt, and four speeds are obtainable. Two forms of feed are fitted; the first is brought into operation by depressing a hand lever, and the second is actuated by revolving a small hand-wheel at the extreme top of the tool. The steel spindle is fitted up with ball bearings, which take up all end thrust and conduce to long life and easy running. The total height is 2ft. 61n., and work sun, deep can be placed between the table—which is /in. in diameter—and the end of the spindle. The price of he machine complete with bracket and pulleys, and including a self-centring chuck, is .4.4 sos

J. Carter, Sons and Company, Limited, of New Bailey Street, Salford, sells an excellent quick-speed, sensitive drilling machine for fine work. The machine, which is capable of drilling a hole 5-16ths in. in diameter and zin. deep, is just the thing for making holes for split-pins and the like. The jib overhangs fin., so that work 12in. in diameter can be accommodated. The spindle, which is lin. in diameter and lain. long, has adjustable bearings for taking up any wear and is counterbalanced for convenience when being used. The driving pulleys which carry the belt have a flat face; they are turned inside and outside. The table is gin. in diameter with a yin. adjustment for taking in any ordinary work. The total weight of the machine is only, approximately, 'so pounds, whilst the height is sft. The price complete is £7 12S.

Charles Churchill and Company, Limited, of 9-1:5, Leonard Street, London, E.C., import and deal, largely, in most descriptions of large and small drilling machines. The gears throughout are cut from the solid, and two speeds are provided. The feed motion is obtained from a bell crank, which works in conjunction with an eccentric on the driving shaft. An automatic device is fitted, and by means of this the feed is stopped at any given point. The worktable is raised by a screw and hand-wheel, on the righthand side, and can be swung round when desired. This machine is made to bolt to an upright, thus saving the floor space which would otherwise be required for its support by feet. The total height is 5ft. gin., and the price of the complete tool is .47.9 iss.