Belting up

Page 93

Page 94

If you've noticed an error in this article please click here to report it so we can fix it.

Bill Brock tries out two seat-belt systems now being considered for van drivers

IF ALL DRIVERS of vans and private cars used restraint systems, 1,500 lives a year would be saved. So I jumped at the opportunity to test two passive restraint methods — alternatives to seat belts — at the Motor Industries Research Association proving ground.

Working drivers should be offered the same amount of protection as may eventually be made compulsory for private drivers.

This is why TRRL awarded a one-year contract to Kangol Magnet Ltd and Accles Britax Ltd totalling £25,000 to develop, and install two types of passive restraint systems in 12 Post Office vans.

A passive restraint system operates automatically without any conscious effort of the user. Post Office workers are frequently getting in and out of their vehicles so the PO vans were considered ideal for a trial of this type.

The first system, one developed by Auto Restraint Systems for the Transport and Road Research Laboratory and manufactured by Kangol Magnet Ltd, is based on a doormounted interia seat belt which automatically fits around the occupant as the door is closed.

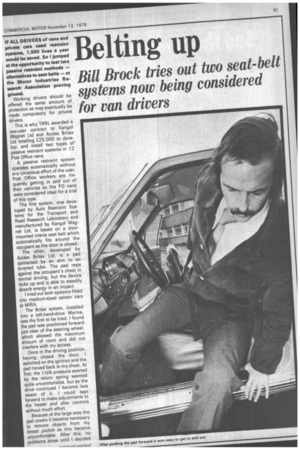

The other, developed by Accles Britax Ltd, is a pad connected by an arm to an inverted tube. The pad rests against the occupant's chest in normal driving, but the device locks up and is able to steadily absorb energy in an impact.

I tried out both systems fitted into medium-sized saloon cars at MIRA.

The Britax system, installed into a left-hand-drive Marina, was the first to be tried. I found the pad was positioned forward just clear of the steering wheel, which allowed the maximum amount of room and did not interfere with my access.

Once in the driving position, having closed the door, I switched on the ignition and the pad moved back to my chest. At first, the 11/21b pressure exerted by the return spring seemed quite uncomfortable, but as the drive continued I became less aware of it. I could lean forward to make adjustments to the heater and alter controls without much effort.

Because of the large area the pad covers it became necessary to remove objects from my breast pocket as this became uncomfortable. After this; no problems arose until I decided to make some violent steering manouevres. Then I found that the support arm, which goes from the chest pad to the restraining mechanism between the seats, restricted arm movements

When decelerating at more than 0.39g the device is designed to lock-in after a 3/4 inch movement and it did just that. I made heavy braking stops, both sitting back in the seat and leaning well forward. Once locked in the energy absorbing unit it provides a further 6in of movement.

Britax has carried out over 100 tests at Byfleet and BSI. The results suggest that it would give a decelleration pattern to that of belted system.

To round off the test. I decided to park on a One-inFour hill in a front downwards direction. I found, that the device locked up and I was unable to vacate the vehicle until resuming a more normal attitude.

No knee restraint was evident in the demonstration car and I learned later from Alan Ellis, project manager for Britax, that it would be required in the Bedford PB vans but not be needed in vehicles designed to meet the American standards 203.

Britax would not give a definate price, but thought £60 or about 21/2 times that of an existing belt system would not be unreasonable if they were produced in similar numbers to seat belts. If modification to the vehicle was required this would be extra, but unlikely as most models now in production meet the required specification.

Later the same day I was able to try out the alternative system fitted in an Allegro supplied by Kangol. Entering the car for the first time I found the diagonal belt fell across the seat as there were no retain

ing locks mounted on the dash. But it required only natural movement to push the belt aside to gain access to the driving seat.

The belt fell neatly across my chest as I closed the door. A knee restraint is provided which, of course, was close to my knees.

The knee restraint consisted of a 90mm rolled steel semicylinder section fitted across the full width of the vehicle. With a single diagonal belt the knee restraint is a legal requirement and is intended to stop the occupant sliding under the belt.

However, Kangol claims that during tests with the single diagonal belt it has been shown to be adequate on its own.

As for the operation of the belt while driving, I noticed little restriction in my movements other than when braking. On the one-in-four hill I was able to open the door and vacate the vehicle with only a

little extra effort — just pushing the belt clear.

The price of the doormounted reel with the emergency release buckle located at the centre of the vehicle between the seats would cost, I was told, about the same as a, conventional belt system.

But the crunch comes when one considers the modification needed to the doors, so thatthe loads can be transferred to the B pillar and the inclusion of the knee restraints. Both are really need to be designed into the vehicle if dealing with large numbers.

Both these systems, in my opinion, normally gave adequate access but became more constricted with a hand-held package. The small faults that I found cart, I am sure, be corrected in detail design.

If I have to make a choice between the two, being conservative in nature, I must go for the belted system.