MAKING THE BEST USE OF MORE POWER

Page 110

Page 113

Page 114

Page 115

If you've noticed an error in this article please click here to report it so we can fix it.

by Paul Brockington, MIMechE

MAKING it simple and comfortable for the driver and giving him ample power that can be used to the best advantage, is a performance target of Pollock (Musselburgh) Ltd, the only Scottish company in the Hilton group.

Mr William George Dunn Pollock and his sons Mr William George and Mr Ian Pollock say they are lucky: their fleet numbers 66 vehicles which is a manageable size, manageable that is in terms of knowing the men and the vehicles in a more personal way, which would not be possible with a much larger fleet. No one is a number; and all the vehicles have names and an individual tartan.

The Pollocks are Gardner-minded men and are sorry that a six-cylinder Gardner has not been developed to cater for the 6 bhp /ton requirement in the case of 32-ton-gross machines and for higher gross weights if or when they are authorized. They consider that the 8LXB is too heavy and too expensive.

When asked whether he would accept a 6LXB that had been turbocharged to produce 20/30 per cent more power, W. G. D. replied that, of course, if Gardner did it, it would be all right. The 10 Scania tractive units operated by Pollock and powered by turbo-charged engines are included in a fleet of 42 30 /32-ton-gross tractive units engaged on long-distance work of which 17 are AtkinSons, the total number of Atkinsons operated by Pollock being 30.

Ina discussion with CM on turbocharging and transmission Mr G. M. Cameron, director and general manager of Atkinson Vehicles (Scotland) Ltd, said turbocharging engines was not favoured by his company because of the poor low-speed torque of the unit. This encouraged the driver to slip the clutch when starting which could greatly increase the rate of clutch wear. However, turbocharging was an inescapable (and acceptable) necessity as a means of obtaining very high powers.

Eight of the Scania tractive units are 110 Supers having a maker's rating of 38-tons-gross and powered by turbocharged diesels developing 275 bhp. Their high power, comfort and low noise level make them popular with the drivers, and the Pollocks say that in the hands of — their — good drivers the vehicles are economic to run by virtue of their good fuel economy and long life, reduced driver fatigue being a concomitant advantage of long-term value. continued on page 111 Giving the driver the kind of gearbox he likes and can use efficiently is a current Pollock preoccupation that centres on an Atkinson 32-ton-gross tractive unit powered by a Cummins 205 diesel mated with a Fuller Roadranger 610 10-speed gearbox which is of the range-change type. Of special importance operationally, the gearbox provides close ratios at the top end that enables the driver easily to select a lower ratio when climbing a gradient at speed on a motorway or the equivalent, and thus maintain the best obtainable speed in an uncomplicated way.

The Pollocks are critical of conventional types of overdrive gearbox because of the wide ratio between overdrive and direct drive, which obviates changing down until the mph of the vehicle has been reduced to a speed that compares unfavourably with a gear-changed speed of the Cummins/Fuller equipped vehicle. They also praise the Fuller gearbox because progression in the separate ranges is readily mastered and applied by an experienced driver and because a low bottom gear facilitates starting without judder or snatch.

The splitter type of box is, they say, less easy to manipulate and bottom gear is normally too high. And the typical driver misuses a two-speed axle by hanging on too long in overdrive, probably because the difference between the direct and high ratios is too great. Progressing downwards from V direct top he normally fails to employ the axle as a splitter. In practice it is employed as an overdrive but not as a splitter.

In the case of the one Cummins /Fuller combination in current use the final drive ratio of the vehicle is 6.28 to 1. Three Cummins-powered Atkinsons with a back axle ratio of 5.75 to 1 are in the pipeline and it is anticipated that the higher ratio will give a useful cruising speed on the motorway of 55/72 mph and reduce journey times.

In a reply to an observation quoted by CM that the close ratios of the top end were welcomed by drivers but there was a preference for wide ratios at the bottom end when travelling in congested traffic, Mr Cameron said this was fair comment. He pointed out, however, that employing a basic gearbox with a range-change auxiliary was the most practical way of providing an easy-change multi-ratio transmission. An SCG semi-automatic gearbox is fitted to a Leyland Beaver tractive unit; it operated satisfactorily while the vehicle was in the sole charge of one driver. A gearbox of this type would not be authorized for a vehicle driven by a number of men which (regrettably) is, of necessity, the normal practice of the company.

In common with many operators of heavy vehicles, the Pollocks would welcome a change in the regulations that would ;nable an eight-wheeler with an acceptable axle spread to gross at 26 tons or better still at 28 tons or more. The 26-ton ;ight-wheeler would in their opinion .ecapture some of the traffic lost to articulated outfits while a 28-ton machine or )ne with a higher rating would regain a very

substantial proportion of the overall traffic.

The 24-ton artic is regarded as an unsatisfactory machine in available form and eight-wheelers are preferred to six-wheeled 22-ton rigids on a number of counts. The fleet includes seven AEC Marshal 22-ton-gross platform lorries the payload of which is within half a ton of the payload of three Atkinson eight-wheelers powered by Gardner 6LXII diesels. Axle overloading resulting from removal of part of the load of a vehicle that initially had a legal gross load is a serious drawback in the use of six-wheelers. The axles of an eight-wheeler, the Pollocks point out, could not be overloaded by removal of part of the load. And compared with an artic they have the all important advantage that the driver remains responsible for the whole vehicle throughout his working day.

No one's baby

Extensive use is made of tarpaulins and the high incidence of damage to the tarpaulins on semi-trailers, as distinct from rigids, is a serious cost factor. And much of the damage to semi-trailers is attributed to the vehicles being "no one person's baby". Obviating neglect of trailers is a major headache of the Pollocks.

No Pollock vehicle is fitted with tubeless tyres or big singles. Damage to wheels by kerbing precludes the use of the tubeless tyres and employing big singles is not considered practical because the high weight of the tyre/wheel assembly makes it impossible for one man to handle an assembly and availability is doubtful in many areas. All vehicles in the fleet carry a spare wheel and this is a tribute to the drivers' honesty, an honesty which in part is fostered by membership of a family concern. The very high cost of calling out a team from a tyre company to replace a cover is normally avoided by carrying a spare. Five of the 72 semi-trailers in the fleet (all of which are Crane Fruehauf or Boden vehicles) are of the three-axled type and it is notable that Pirelli SM55 tyres give a mileage life of 100,000 (plus) which compares with the life of 50,000/60,000 in the case of trailers having widespread tandem bogies. A test set of Dunlop SP11 radials on a Leyland Beaver tractive unit ran for 125,000 miles before replacement.

Responsibility of the individual and supervision of his work by responsible personnel are concepts that are considered essential to proper maintenance and operation of the fleet. Specialists on the staff include a tyre maintenance man, an electrician, a paintshop foreman and a coach builder. All major repair work is

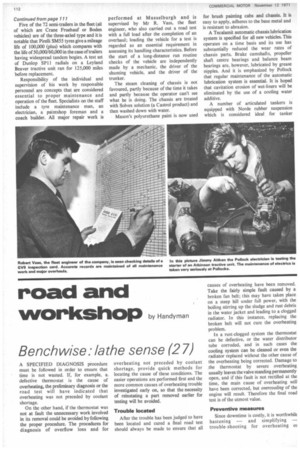

performed at Musselburgh and is supervised by Mr R. Vass, the fleet engineer, who also carried out a road test with a full load after the completion of an overhaul; loading the vehicle for a test is regarded as an essential requirement in assessing its handling characteristics. Before the start of a long-distance run routine checks of the vehicle are independently made by a mechanic, the driver of the shunting vehicle, and the driver of the trunker.

The steam cleaning of chassis is not favoured, partly because of the time it takes and partly because the operator can't see what he is doing. The chassis are treated with Solvex solution (a Castrol product) and then washed down with water.

Mason's polyurethane paint is now used for brush painting cabs and chassis. It is easy to apply, adheres to the base metal and is resistant to abrasion.

A Tecalamit automatic chassis lubrication system is specified for all new vehicles. This operates on a time basis and its use has substantially reduced the wear rates of chassis parts. Brake camshafts, propeller shaft centre bearings• and balance beam bearings are, however, lubricated by grease nipples. And it is emphasized by Pollock that regular maintenance of the automatic lubrication system is essential. It is hoped that cavitation erosion of wet-liners will be eliminated by the use of a cooling water additive.

A number of articulated tankers is equipped with Norde rubber suspension which is considered ideal for tanker applications because of its long life, freedom from maintenance requirements and, of special importance, the high roll resistance it provides. While load-apportioning valves are favoured (none of the semi-trailers is equipped with them) the Pollocks consider that there is room for considerable improvement in their design and in their application to all the axles of a semi-trailer outfit. Maintaining brake efficiency between maintenance docks is highly desirable, in the Pollock view, on the grounds of safety. SAB automatic adjusters are fitted to the latest semi-trailers and to two tractive units. These adjusters automatically compensate for thermal expansion of the brake drums and this eliminates the possibility of the brakes locking-up after cooling and allows small tolerances to be used.

In addition to the main depot at Musselburgh, the company, operates depots in Coatbridge near Glasgow, Ditchbum Street, London E14, and Brierley Hill in the Birmingham area. Assistance is available from other Hilton depots throughout the country.

Loads on trunking and tramping runs by articulated outfits include steel from Coatbridge to the Birmingham, London and St Helen's areas (the fleet includes a number of coil carriers) and there is a considerable amount of container traffic, both long-distance and local. Carpets are carried in rigid vans on tramping runs for destinations that include Birmingham and London. rigid lorries have to be employed on some of the steel runs because difficult access precludes the use of artics. Six tankers with capacities up to 5000gal are normally employed on local work. Two semi-low-loaders are designed for carrying high transformers, and it is notable that the delivery of the transformers must be strictly on time to coincide with the "booked" time of the cranes employed for unloading. If the vehicle is late Pollock has to pay for waiting time.