An Aircooled di 1

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

En

me Explained

WHILST the water-cooled petrol engine for aircraft . does not strike the roadtransport operator in an unfamiliar light, the air-cooled type is often of quite different construction. To remove any idea that. theradial engine is a stranger to which fitters and foremen would take considerable time to get accustomed, we propose this week to explain simply the design of a typical British unit and what its maintenance involves.

We choose the Pobjoy R 75 b.h.p. engine because it has characteristics of simplicity and lightness of weight, has proved itself reliable, is used in commercial aircraft and incorporates a reduction gear. We wish to explain the reduction gear. ,

Between air-cooled and watercooled engines the struggle has long persisted, the former gaining on weight what it loses on wind resistance. To reduce the latter factor to a minimum Pobjoy Airmotors, Ltd., Hooton, Cheshire, set out to obtain extreme compactness, even with a radial type, also reducing weight.

Small Bulk Gives Rigidity and Lightness.

The small bulk of the engine and its components rendered comparatively high crankshaft Speeds possible, so that with a 2.835-litre capacity (bore 77 mm., stroke 87 mm.) 77-79 b.h.p. is obtained at 3,000 r.p.m., and a peak of 85 b.h.p. at 3,300 r.p.m. The airscrew is geared down from 3,000 r.p.m. to 1,403 r.p.m. That a high crankshaft speed need not involve rapid wear has been evidenced in practice, so that the period between complete

overhauls is now increased from 300 hours to 450 hours (say 45,000 miles of travel).

The weight with airscrew hub is 135 lb. plus 8 lb. for exhaust collectors, equal to no more than 1.682 lb. per b.h.p. The overall diameter is only 26 ins. From the first the figures indicate an interesting unit. The light-alloy crankcase is in four parts (a central part holding the cylinders, another enclosing the valve gear, and two end pieces) and it carries the patented two-piece

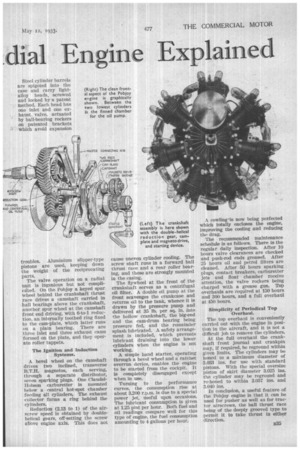

Performance data of the Pobjoy engine are given in this graph. Whilst described as a 75 b.h.p. unit, the engine develops about 78 b.h.p at normal speed, and has a maximum output of 85 b.h.p. The rapid fuel-consumption rise at speeds above 3,200 r.p.m. is due to a power jet being brought into operation at Athrottle opening, which, of course, is far above cruising speed.

single-throw crankshaft in four bearings, a plain bearing at the front, a roller bearing each side of the throw and a ball thrust bearing at the rear. The hardened crankpin carries a floating bronze bush running in the hardened eye of the master connecting rod, to which the six steel articulating rods are linked.

troubles. Aluminium slipper-type pistons are used, keeping down the weight of the reciprocating parts. The valve operation on a radial unit is ingenious but not complicated. On the Pobjoy a keyed spur wheel behind the crankshaft thrust race drives a camshaft carried in • ball bearings above the crankshaft, another spur wheel at the camshaft front end driving, with 6-to-1 reduction, an internally toothed ring fixed to the cam-plate, which latter runs on a plain bearing. There are three inlet and three exhaust cams formed on the plate, and they operate roller tappets.

The Ignition and Induction Systems.

A bevel wheel on the camshaft drives two inclined, transverse B.T.H. magnetos, each serving, through a separate distributor, seven sparking plugs. One Claudel:Hobson carburetter is mounted below a central hot-spot chamber feeding all cylinders. The exhaust collector forms a ring behind the cylinders.

Reduction (2.13 to 1) of the airscrew speed is obtained by doublehelical gears, off-setting the screw above engine axis. This does not cause uneven cylinder cooling. The screw shaft runs in a forward ball thrust race and a rear roller bearing, and these are strongly mounted in the casing.

The flywheel at the front of the crankshaft serves as a centrifugal oil filter. A double oil pump at the front scavenges the crankcase and returns oil to the tank, whence it is drawn by the pressure pump and delivered at 35 lb. per sq. in. tinto the hollow crankshaft, the big-end and the cam-drum bearing being pressure fed, and the remainder splash lubricated. A safety arrangement is included, which prevents lubricant draining into the lower cylinders when the engine is not working.

A simple hand starter, operating through a bevel wheel and a ratchet overrun device, enables the engine to be started from the cockpit. It is completely disengaged except when in use.

Turning to the performance curves, the consumption rise at about 3,200 r.p.m. is due to a special power jet, useful upon occasions. The lubricant consumption is given at 1.25 pint per hour. Both fuel and oil readings compare well for this type of engine, the fuel consumption amounting to 4 gallons per hour.

A cowling 'is now being perfected which totally encloses the engine, improving the cooling and reducing the drag.

The recommended maintenance schedule is as follows. There is the regular daily inspection. After 10 hours valve clearances are checked and push-rod ends greased. After 25 hours oil and petrol filters are cleaned. After 50 hours sparking plugs, contact breakers, carburetter jets and float chamber receive attention, the valve rockers being charged with a grease gun. Top overhauls are required at 150 hours and 300 hours, and a full overhaul at 450 hours.

Simplicity of Periodical Top Overhaul.

The top overhaul is conveniently carried out With the engine in position in the aircraft, and it is not a difficult job to remove the cylinders.

At the full overhaul the crankshaft front journal and crankpin may, if required, be reground within given limits. The cylinders may be honed to a OfaXIMUlit diameter of 3.033 ins, for use with standard pistons. With the special oversize piston of skirt diameter 3.025 ins. the cylinder may be reground and re-honed to within 3.037 ins. and 3.040 ins.

In conclusion, a useful feature of the Pobjoy engine is that it can be used for pusher as well as for tractor airscrews, the ball thrust race being of the deeply grooved type to permit it to take thrust in either direction.