Big Cartage Contractor Likes Government Plant

Page 31

Page 32

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

Five Improved G.E.P. Producer-gas Units and Five B.C.U.R.A. Outfits are Giving Satisfaction in the Hands of Carter Paterson and Co., Ltd., which Concern

is Testing Them.

THERE has been talk, recently, notably in the Houses of Parlia ment, about the number of producer-gas plants that have been made and distributed and the number of those that are in use. It has been pointed out that the former is much. greater than the latter, and it has been alleged that the majority of the balance comprises Government " Emergency" producers, generally known as G.E.P. plants.

An implication has been made that these units have proved so unsatisfaci tory that operators, who acquired them in the first instance, laid them aside as virtually useless.

In fairness to the G.E.P., and to the advantage of the producer-gas movement in general, we wish to dispel the false impression that has been created. Whilst there has certainly been a number of cases of dissatisfaction, which has not been limited to any particular type of apparatus, the real reason for the big difference between the number built and the number in service is that certain long-sighted operators purchased big batches of producer-gas outfits with no intention of using them immediately, but to hold in readiness against an acute liquidfuel shortage, and thus to equip thenmelves to avoid a crisis through immobilization of road transport. In this way the majority of the Emergency plaats not in actual use can be satisfactorily accounted for.

As an example, we can name Carter Paterson and Co., Ltd. This company, in the relatively early days, took a big part in testing various plants, and ran many vehicles on producer gas with the chief object of studying the possibilities, familiarizing its personnel • with the technique, and effecting improvements in design, Soon after the outbreak of war it was running 30 G.E.P. trailer units and 10 B.V.P. " built-in " outfits or " conversions." The mileages' of the respective vehicles using solid fuel in this way ran to many thousands.

Subsequently it reduced the number to eight vehicles which were kept in service and are still running. Since the beginning of February of this year, and working in close co-operation with the Mines Department, Carter Paterson and Co., Ltd., has been bringing additional vehicles into use on producer gas. It is now running, under observation, five improved Government plants and five B.C.I.T.R.A. outfits, all mounted on trailer chassis and all coupled to Bedford 5-tonners.

These vehicles are being operated under ordinary service conditions, carry practically full loads all the time and work on routes ranging from 70 to 150 miles in length.

In addition, it has a large number standing idle in reserve. These will no doubt be brought intO use at the die cretion .of the company. .

So far as speed and power on the road are concerned, we are informed that there is little to choose between the two types. The G.E.P., we understand, can be rendered operative more quickly, from a cold start, and the vehicles running in conjunction with plants of this type consume, in the

aggregate, less petrol. Servicing is easier with the G.E.P.

All the plants are being run on activated c Le fuel, prepared at 30-40 degrees C. below the normal high temperature, and having a c.a.b. (critical air blast), 7 reactivity value, of 0.038.

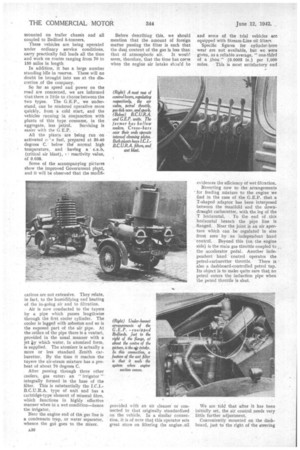

Some of the accompanying pictures show the improved Government plant, and it will be observed that the modifi cations are not extensive. They relate, in fact, to the humidifying and heating of the in-going air and to filtration.

Air is now conducted to the tuyere by a pipe which passes lengthwise through the first cooler cylinder. The cooler is lagged with asbestos end so is the exposed part of the air pipe. At the orifice of the pipe there is a venturi, provided in the usual manner with a jet toy which water, in atomized form, is supplied. The atomizer is actually a more or less standard Zenith carburetter. By the time it reaches the tuyere the air-steam mixture has a preheat of about 70 degrees C.

After passing through three other coolers, gas enter.; an " irrigator " integrally formed in the base of the filter. This is substantially the I.C.I.B.C.U.R.A. type of unit and has a cartridge-type element of mineral fibre, which functions in highly effective manner when in a wet condition—hence the irrigator.

Near the engine end of tha gas line is a condensate trap, or water separator, whence the gaS goes to the mixer. Before describing this, we should mention that the amount of foreign matter passing the filter is such that the dust content of the gas is less than that of atmospheric air. It would. seem, therefore, that the time has cone when the engine air intake shaa'd be provided with an air cleaner or connected to that originally standardized on the vehicle. In a similar connection, it is of note that this operator sets great store on filtering the engine ,oil and some of the trial vehicles amo equipped with Stream-Line oil filters.

Specific figures for cylinder-bore wear are not available, but we were given, as a reliable average, " one-thtrd of a _thou " (0.0003 in.) pot 1,000 miles. This is most satisfactory and evidences the efficiency of wet filtration. Reverting now to the arrangements

• for feeding mixture to the engine we find in the case of the G.E.P. that a T-shaped adaptor has been interposed between the manifold and the downdraught carburetter, with the leg of the

'I' horizontal. To the end of this horizontal branch the pipe line is flanged. Near the joint is an air aperture which can be regulated in size from zero by an independent hand control. Beyond this (on the engine side) is the Main gas throttle coupled to the accelerator pedal. Another independent hand control operates the petrol-carburetter throttle. There is also a dashboard-controlled petrol tap. Its object is to make quite sure that no petrol enters the induction pipe when the petrol throttle is shut.

We are told that after it has been initially set, the air control needs very little further adjustment.

Conveniently mounted on the dashboard, just to the right of the steering wheel, are four fairly large levers. These regulate, respectively, the air valve, the petrol throttle, the gas slow. running adjustment (it also holds the gas throttle open for starting the producer) and the ignition timing.

From our illustrations of the B.C.U.R.A. plant, it will. be seen that this also employs a wet blast and is equipped with the I.C.I.-B.C.U.R.A. -filter. The producer, however, is of the up-draught type, whilst the G.E.P. operates on the cross-draught principle, although a ,horizontal tuyere is provided on the former for expediting starting.

Another difference is that the coolers, of which there are only two, are annular in cross-section. For cleaniog \these, there is an annular plate inside .attached, by two rods, to the crossbar sem across the end of each cooler in one of the pictures. By slackening two wing nuts the bar is freed and the plates eau be drawn from end to end of ' the coolers, thus dislodging deposits, and ejecting the accumulated matter.

Water vapour and in-going air are preheated in a jacket sun-Minding the firebox, The platform over the filter is, of course, for filling the hopper, As before there is a condensate trap, and on all 10 vehicle:, a daily operation is to drain this, and to wash out and refill the filter. The last-named is also topped up at every stop for refuelling, that is, about every 70 miles when carrying a 5-ton load.

Gas-mixing arrangements are somewhat different on the B.C. U. R. A.equipped Bedfords. As before there is a separately controlled air-intake valve, but the gas and petrol throttles are interconnected so that the accelerator

operates both. Therefore, a changeover valve is provided in the junction of the petrol and gas induction pipes.

Provision is made in the throttle interconnecting gear for individual idling adjustment.

There is no petrol tap in this system and the petrol consumption is slightly higher, but this is not necessarily due to leakage past the change-over valve. As we have ,already stated, both plants are performing to the operator's satisfaction, and the chief point that arose from our investigation and discussion of the company's experiences and opinions, was not which of the two was the better, but that tha G.E.P: was by no means a useless contraption, as had been implied in certain quarters on more than one recent occasion. Actually we detected a preference for the G.E.P., but this seemed to be based upon its greater simplicity in respect of construction and maintenance, th,e performance of the two types being approximately the same.

These 10 plants are part of the 200odd units which are being kept under observation by the Shearman Committee, working in close co-operation with the Mines Department, In the hands of a large number of operators, the vehicles to which they are attached, as trailer outfits or built-in sets, have covered between them nearly 6,000,000 miles, and the Committee has the reports on them all.