TIMMS DELIGHT

Page 58

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

Mercedes new Axor Powershift was displayed at the \EC earlier this year, but how does it perform on the road?

Colin Barnett took it for a particularly challenging drive.

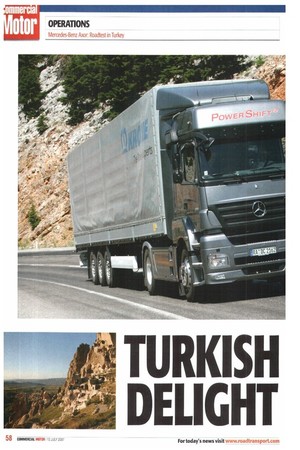

• hen it was launched, the Mercedes Benz Axor followed a simple formula, fed by the German giant's global parts bin. Pop a 2.3m-wide cab on an Actros chassis, power it with a simple 12-litre straight-six engine from Brazil driving through a basic nine-speed manual gearbox and keep the options list brief Intended to fill the gap between Atego and Actros, the Axor was unashamedly aimed at fleets.

However, fleet buyers today have raised their standards and demand more. In particular, automated transmissions have become significantly more acceptable and at the NEC in April, Mercedes displayed the Axor Powershift 12, featuring a slightly featurereduced version of the automated gearbox already titled to the Actros.

Challenging the Powershift All too often, our first drive of new trucks amounts to an easy cruise along some Western European motorway. For the Axor Powershift, Mercedes came up with a rather more challenging event:a one-day trek from the southenaurkish resort of Antalya to the Factory at Aksaray, 450km to the North-West, that gave the Axor its name. On the way we climbed up and down 6,000ft mountains in heat that needed the melting asphalt to be

gritted, crossed a 140km-wide plateau in a virtually straight line, passed mud houses with satellite dishes and battled through anarchic Turkish provincial cities in a loose convoy of 16 identical Axors.

The Axors were I 843LS models with Euro-5 engines developing 422hp and 2,100Nrn, driving through the new G211-12 Powershift transmission and a Voith R 115 HV retarder. The electronically controlled 12-speed transmission uses engine speed and a layshaft brake to match speeds and eliminate the synchromesh.A weight saving of 40kg compared with a manual nine-speeder is calculated by Mercedes.

The Powershift controller will be familiar to anyone who's driven a Telligent pre-selector Mere, with a fore-and-aft joystick mounted on the arm-rest. Press the safety button, nudge forward and you're away. An A/M button behind selects auto or manual modes, and a toggle at the front gives split (single-ratio) changes in manual, with the main stick giving full two-ratio steps.Nudg,ing the stick in Auto overrides the computer to change down for improved engine braking. Pressing the accelerator pedal restores Auto mode.

Other transmission-related features include manoeuvring mode, which reduces the engine speed to 1,000rpm and allows direct first-to When Mercedes-Benz decided to build a factory in Turkey, it chose a country almost as large as France and Germany combined, stretching from Bulgaria in the west to Iran in the east, with a high dependence on road transport.

Today, 21 volatile years after production of the first truck, and following major slumps in 1994 and 2000, Mercedes can lay claim 30% of the Turkish market above six tonnes with the Axor seen very much as a local product.

This market has exploded from some 8,000 units in 2001 to 42,000 in 2006.

The automotive industry is a significant part of the Turkish economy, second only to textiles. As well as satisfying local needs, the icing list of Turkish-built vehicles running on UK roads includes the Toyota Corolla Verso, Fiat Doblo and Ford Transit/Transit Connect, not to mention some Axor 8x4 tippers.

The Axor factory in Aksaray, on the old Silk Road to the East, is the most easterly of Turkey's automotive plants, just 290km from the Syrian border. This does no harm to its potential as a bridge to the iucrative Middle-East markets.

While chassis rails and driveline components make a seven-day road trip from Germany, cabs and many ancillary components are manufactured on site. The 1,350 workers are on course to produce 16,000 Ategos, Axors and Unimog U4000s this year, in a plant that matches anything further West in terms of working conditions.

Quality is monitored to the same standard as in other M-B facilities.