An Economical Short-haul LV-tonner

Page 54

Page 57

Page 58

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

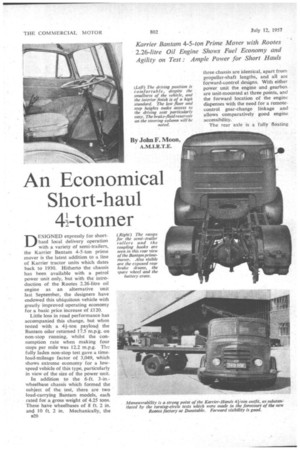

DESIGNED expressly for shorthaul local delivery operation with a variety of semi-trailers, the Karrier Bantam 4-5-ton prime mover is the latest addition to a line of Karrier tractor units which dates back to 1930. Hitherto the chassis has been available with a petrol power unit only, but with the introduction of the Rootes 2.26-litre oil engine as an alternative unit last September, the designers have endowed this ubiquitous vehicle with greatly improved operating economy for a basic price increase of £120.

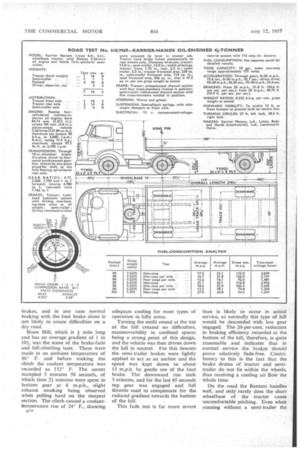

Little loss in road performance has accompanied this change, but when tested with a 41-ton payload the Bantam oiler returned 17.5 m.p.g. on non-stop running, whilst the consumption rate when making four stops per mile was 12.2 m.p.g. The fully laden non-stop test gave a timeload-mileage factor of 3,049, which shows extreme economy for a lowspeed vehicle of this type, particularly in view of the size of the power unit.

In addition to the 6-ft. 3-in.wheelbase chassis which formed the subject of the test, there are two load-carrying Bantam models, each rated for a gross weight of 4.25 tons. These have wheelbases of 8 ft. 2 in. and 10 ft. 2 in. Mechanically, the a20 three chassis are identical, apart from propeller-shaft lengths, and all are forward-control designs. With either power unit the engine and gearbox are unit-mounted at three points, and the forward location of the engine dispenses with the need for a remotecontrol gear-change linkage and allows comparatively good engine accessibility.

The rear axle is a fully floating unit with spiral-bevel feduction gearing. The prime mover has a 7.166to-1 axle, whilst the load carrier.; have 6.57-to-1 final drives. Girling two-leading-shoe brakes are fitted, with a Lockheed master cylinder. A peculiarity of the braking system is that no means is provided for the foot brake to operate the trailer brakes, these being actuated solely by a separate lever in the cab.

Two types of automatic coupling ;ear are offered with the Bantam tractor. The J-type gear, as fitted to ,he test vehicle, has twin ramps for engagement with small rollers on the semi-trailer undercarriage, these rollers being clamped in place to lock the coupling. An important advantage of the J-type coupling is that a tractor so equipped can be used in conjunction with Scammell MH3 3-ton semi-trailers, although a Scammell tractor cannot be used with J-type trailers.

Fully Automatic Coupling

The other coupling gear offered With the Bantam is the BK type, which is fully automatic in that the driver does not have to leave the cab to apply the trailer brake before Uncoupling. Trailers with the BKtype coupling have rigid support legs • which rest on each side of the tractor rear wheels when the unit is coupled, whereas the J-type gear has retractable legs which swing back When coupling.

An all-steel cab, similar to that used with the larger Karrier Gamecock models, is fitted as standard equipment. This has two bucket-. type seats, and because of the low cab floor and step heights, access to either of these seats is particularly. easy, although it is not possible to reach the driver's seat from the nearside door without clambering over the engine cowl. The semi-trailer supplied for test with the Bantam was a Hands JSSF 4-5-ton model. This, like the prime mover, was carrying 25 x 6 (8-ply) tyre equipment, thus ensuring complete tyre interchangeability throughout the unit. The trailer had a 15-ft platform body; this was 7 ft. wide and had an 18-in. head-board. The kerb weight of the outfit, complete with test equipment and spare filet, was 2 tons 17-1 cwt., and a 4+-ton test load was carried. A distribution check showed that the front-axle loading was sufficient to assure complete steering stability.

A distance of 850 miles had been covered before the test, so the chassis was reasonably well run-in and mechanically loose. Acceleration tests were run off first, and the results obtained show that despite the low power-to-weight ratio the Bantam. can get off the mark quite smartly,. the synchromesh gearbox being a big help in this respect: All four gears were used for the 0-30 m.p.h. !test.. The direct-drive runs revealed commendable transmission smoothness at low speed, the engine pulling away without fuss from 8 m.p.h. in top gear. This is a useful asset for town working, reducing the amount of gear-changing necessary under such conditions.

For the fuel-consumption tests, a 6-mile out-and-return circuit between Barton and Cloph ill, on the A6 road, was used, this being an undulating route known to give representative results. Seven runs were made in all, as detailed in the fuel-consumption analysis, carrying a full load, a 21-ton load, and running without the trailer. When making stops to simulate local delivery conditions, each stop was of 15 seconds duration, the engine being left idling each time. The fuel-consumption results' obtained show that with part of the load removed there is a substantial. improvement in the consumption rate when running non-stop, but that under delivery conditiOns. •the improvement is not so marked. It is reasonable to suppose, therefore, that when engaged on the work for which it was designed the Bantam will return an average consumption rate in the region of 15 m.p.g., assuming a constantly decreasing load on each delivery round, although with a high percentage ol' unladen running figures nearer 20 M.p.g. should be -obtained.

Tractor Driven Hard

For these tests the tractor was driven hard, up to 30 m.p.h. being maintained when running non-stop and 25 m.p.h being reached between stops, even when making one stop every quarter of a mile. The theoretical maximum. speed of the vehicle at the governed engine speed is 33 m.p.h., but with governor overrun the road speed can rise to nearly 40 m.p.h. at times.

The braking tests were conducted on a dry asphalt road and the semitrailer brakes were applied manually at the same time as the foot brake was depressed. The maximum deceleration recorded on the Tapley meter on each occasion showed negligible time lag when compared with the average stopping distances.

It was noticed that on each occasion all the wheels of the prime mover locked when braking at full pedal pressure, thereby emphasizing the need for instant braking at the semi-trailer when making emergency stops. From the large number of Bantam tractors already in service, however, it would appear that their drivers are used to braking with manual actuation of the semi-trailer brakes, and in any case normal braking with the foot brake alone is not likely to create difficulties on a dry road.

Bison Hill, which is mile long and has an average gradient of 1 in 10+, was the scene of the brake-fade and hill-climbing tests. These were made in an ambient temperature of 46° F. and before making the climb the coolant temperature was recorded as 152° F. The ascent occupied 5 minutes 50 seconds, of which time 21 minutes were spent in bottom gear at 6 m.p.h., slight exhaust smoking being observed when pulling hard on the steepest section. The climb caused a coolanttemperature rise of 24° F., showing adequate cooling for most types of operation in hilly areas.

Turning the outfit round at the top of the hill created no difficulties, manoeuvrability in confined spaces being a strong point of this design, and the vehicle was then driven down the hill in neutral. For this descent the semi-trailer brakes were lightly applied to act as an anchor and the speed was kept down to about 15 m.p.h. by gentle use of the foot brake. The downward run took 3 minutes, and for the last 45 seconds top gear was engaged and full throttle used to compensate for the reduced gradient towards the bottom of the hill.

This fade test is far more severe than is likely to occur in actual service, as normally this type of hill would be descended with low gear 'engaged. The 20-per-cent. reduction in braking efficiency recorded at the bottom of the hill, therefore, is quite reasonable and indicates that in normal service the brakes -should prove relatively fade-free. Contributory to this is the fact that the brake drums of tractor and semitrailer do not lie within the wheels, thus receiving a cooling air flow the whole time.

On the road the Bantam handles well, and Only rarely does the short wheelbase of the tractor cause uncomfortable pitching. Even when running without a semi-trailer the

tractor is quite stable, although it is advisable to avoid heavy braking under this condition because of the extremely light rear-axle loading: The steering is quite light, as may he expected, but at no time during the test did wander become marked.

The driving position is surprisingfy comfortable in view of the smallness . of the vehicle, and although the space around the pedals is a little cramped because of the size of the engine cowl, there is sufficient " resting ", room for the left foot. Generally the engine noise level in the cab' is low, additional sound insulation being provided by a loose padded cover which clips over the engine cowl.

Occasionally slight engine vibration was felt in the cab, particularly when idling, but this. was most probably because the idling speed setting was on the slow side:

Considering. the class of work 'upon which this type of vehicle is invariably engaged, the cab interior finish is of a high standard. A good set of instruments is provided, and a useful interior lamp is set into the cab roof-lining panel. Only one driving mirroris fitted as standard, and . I consider that two should always be provided with a prime mover. The glazed rear corners are a great help when shunting in confined spaces, however, and when approaching acute-angled road junctions. Forward visibility is good, and twin windscreen wipers are standard.

Flimsy Spanners Apart from one or two fiddling little jobs on the engine, maintenance of the Bantam presents no real difficulties, and is decidedly easier than on many forward-control designs. A good set of tools is provided, although the three open-ended spanners are too flimsy for any serious work on the chassis. It would also be a good idea if the makers of the engine were to provide some special spanners for the power unit and its ancillary equipment.

A water-level check took me 13 seconds, and I then inspected the engine oil level in 50 seconds, noting that dip-stick and oil-filler are on the same side of the engine. A dip-stick is provided in the gearbox, adjacent to the change-gear-lever tower, and is accessible through a hole in the cab floor, this being sealed by a large rubber plug. I was able to check the gearbox oil level in 30 seconds without difficulty. The gearbox is topped up through this dip-stick hole, the stick itself sealing the orifice. The rear axle is fully exposed for ,ttention when the serni-trailer is removed, arid it was a pleasant change to be able to Check the axle oil level without having to crawl beneath the vehicle. A combined tiller and level plug is provided and it took me 50 seconds to check the oil level.

There are two 6-volt batteries, housed. in a crate on the 'near-side chassis meinber,, just behind the c,a.b. The 'batteries. are secured by a Wooden lid which is retained by two self-kicking nuts. These nuts .takc Uttite.a while to remove, and it took tne; 2+ minutes to remove the cover, 45 seconds to check the cell levels, and 3 minutes to replace the cover. With a different bracket layout and wing nuts this job would have been completed in under 2 minutes instead of the 6 minutes that I took.

Easy to Adjust Running adjustment of the brakes is a simple matter, it being unnecessary to jack up the wheels because of the Girling wedge adjusters fitted. Furthermore, the same spanner can be used on front and rear brakes, and there is only one adjuster per wheel. I was able to adjust all fourbrakes in 3 minutes, therefore, whilst checking the brake-fluid level took • only 8 seconds, the reservoir" being clipped to the steering column.

The spare wheel is stowed on top of the chassis frame, behind the cab, and its small size makes it easy to handle. Two nuts secure the wheel and the wheelbrace fits these, so I was able to remove the wheel in 50 seconds and restow it in 1 minute.

The engine cowl top section can be removed in 5 seconds ((lie same time being required to detach the loose cover) and with this top removed l stripped down the air cleaner and checked its oil level in 2 minutes. This entailed loosening one hose clip and removing a wing nut. Working from the near side of the cab, I removed an injector in 44 minutest minute to loosen all the joints, and 31 minutes to free the injector from the cylinder head. Replacement took 3+ minutes. MI the injectors are equally. accessible.

Engine Cowl Trap . A trap in the left-hand side of the engine cowl gives access to the fuelinjection pump, and through this the fuel filter can be reached also, although the hole is the wrong shape to allow the filter or its element to be withdrawn through it. By forcing the bowl between the front bulkhead and the air cleaner I was able to remove the element in 2 minutes, but replacement took a further 4 minutes.

Bleeding of the fuel system is a little complicated because of the design of the distributor-type injection pump and the ridiculously small priming handle on the fuel-lift pump.

had to vent the system-at the filter, the injection pump, and one of the injectors, this all taking a total time of 16 minutes.

Removal and replacement of the crankcase-ventilation filter element took 50 seconds—this item requires attention every 5,000 miles—and as a final taSk I changed one of the four fuses in 12 seconds. The fuses are located on the front bulkhead, in front of the steering colunm. Replacing the engine-cowl top took 15 seconds, and the cover took a further 25 seconds to fit.

The Bantam oil-engined tractor has a basic price of £850, British purchase tax adding £143 13s. 4d., and the 15-ft. semi-trailer used in the test costs £338, plus £6 I0s. for the head-board.