THE DENNIS MOTOR MOWING MACHINE.

Page 15

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

An Interesting Departure From Previous Practice.

T" DENNIS motor mowing machine which was shown at Derby strikes quite a new note. The machine is constructed as a Compact unit, in the framework of which no tubes are used. The workmanship is of the highest quality, and the price only .B5.

The machine 'coniplete weighs about 3 cwt., and is driven by a small twostroke engine, the bore and stroke of

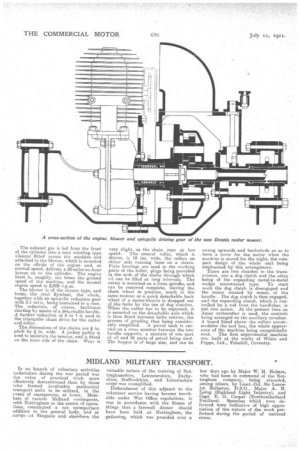

which are 2i ins. by 3 his. A number of interesting features are incorporated in the-design of the motor. The radiating flanges are 1L ins, deep, and the ports are eiceptionally large and wide, and are cast with a central web which tapers off well.into the walls of the cylinder with a view to getting the heat away. The object. of this central web is to ,,up

port. the two piston rings. The piston bead is machined all over, as is the inside of the cylinder head. •. The gudgeon pin bosses are stiff, and special provision has been made to prevent. the possibility of the top ring sticking a common failure in two-strokes. High crankcase compression is used, the crank and the, balance weight being built up in such a way as to secure great rigidity and strength. The exhaust gas is led from the front of the cylinder into a neat whirling type silencer fitted across the machine and attached to the blower, which is mounted on the offside of the engine and, at normal speed, delivers a 30-miles-an-hour breeze on to the cylinder. The engine blast is, roughly, ten times the ground speed of the machine, and the normal engine speed is 2,000 r.p.m.

The blower is of the sirocco type, and forms the steel flywheel, the whole, together with an epicyclic reduction gear with 3-1 ratio, being contained in a case. The reduction, of course, facilitates starting by means of a detachable handle. A further reduction of 8 to 1 is used in the triangular chain drive for the cutter and roller.

The dimensions of the chains are in. pitch by in. wide. A jockey pulley is used to maintain the tension, and is fitted on the loose side of the chain. Wear is very slight, the chain runs at low speed. The central roller, which is

driven, is 18 ins, wide, the rollers on either side running loose on a sleeve. Plain bearings are used in the working parts of the roller, plugs being provided in the ends of the shafts through which oil can be filled at long intervals. The cutter is mounted on a loose spindle, and can be removed complete, leaving the chain wheel in position, much in the same manlier as a quick detachable back wheel of a motor-bicycle is dropped out of the forks by. the use of dog clutches. When the cutter has to be reground, it is mounted on the detachable axle which is then fitted between lathe centres,.the process of grinding thus being consider ably simplified. A petrol tank is carried on a cross member between the two handle supports, a mixture of one part of oil and 16 parts of petrol being used: 'fly hopper is of large size, and can be

swung upwards and backwards so as to form a cover for the motor when the machine is stored for the night, the compact design of the whole unit. being emphasized by this arrangement. There are two clutches in the transniission, one a dog clutch and the other being of the expanding metal-to-metal wedge accentuated type. To start work the dog clutch is disengaged and the motor rotated by means of the handle. The dog clutch is then engaged, and the expanding clutch, which is controlled by a rod from the handlebar, is put into action. At the present time an .Amac carburetter is used, the controls being arranged on the auxiliary crossbar, A board fitted above. the rollers accommodates the. tool box, the whole appearance of the machine being exceptionally neat. The first experimental machine was built at the works of White and Poppe, Ltd., Foleshill, Coventry.