Experiences with Coal-gas.—No. VII.

Page 4

If you've noticed an error in this article please click here to report it so we can fix it.

Linked or Independent Control of Gas-cock (Stop-tap) and Throttle-valve.

It is only natural, having regard to the comparative novelty af the use of coal-gas for propulsion on common roads that there should be a division of opinion between users as to the. best method of coupling up. Messrs. Andrew Barton Bros., of Beeston. Notts., the pioneers of this form of traction under present-day conaitions, have shown a marked preference for linked control, in accordance with the -illustrations which ws have nublished on several occasions. They have, 'however, as the following letter discloses also made tests of the method by which_ the outflow from the gas-supply pipe is not varied by positive control in link with the throttle-valve, but is only subject to the checking or total shutting-off of the gad, by means of a separate cock (stop-tap) near the driver.

A User's Views.

The following letter, written under date the 7th inst. has 'been addressed to us by Mr. Percy Dougall, Assec.M.Inst.C.E., engineer and manager of the, Kidderminster Gas Co., in further reference to the running data. on which we were able to,base the first article of this series (issue of the 24th May last):—

[edam]

I have followed with, great interest and a.ppreoiation.the articles in THE COMMERCI&L MOTOR and associated papers but clo.not consider the connections for the gas into the motor, whim you have shown and:dOscribed, in several of the articles, as the simplest for

anyone desirous of experimenting with the use of gas, though I admit that the method you show may be advantageous when fixed and regulated by an expert.

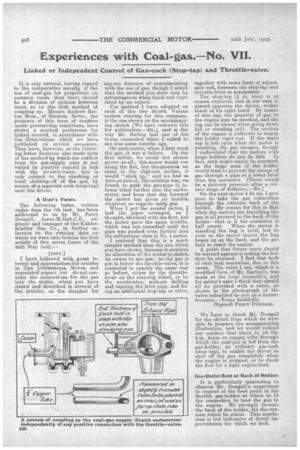

The method I have adopted on each of the two 30-cwt. Vulcan motors running for this company, is the one shown on the accompanying sketch [We have redrawn this for publication.—End, and isthe way Mr. Barton had one of his buses connected when I called to see him some months ago. On eachanotor; when Lfirst, tried the gas, it was a failure. On the first motor, we could not obtain power at,a11; themotor would run along the flat, but themlonaeat we came to the slightest incline, it would "stick up," and we had to turn on petrol:. The solution was, we found, to push the gas-pipe (i in. brass tube) further into the carburetter, and from that day forward the motor has given no trouble whatever as regards using gas. When I got' the second motor, I had the pipes arranged, as I thought, identical with the first, but the motor gave the same trouble, which was not. remedied until the pipe was pushed even further into the caiburetter than in No. I motor.

I contend that this. is a much simpler methed than the one which you have shown, because it requires no alteration of the motor to enable its owner to, use gas ; as the gas is put in below the throttle-valve, it is controlecl in exactly the same way as before, either by the throttlelever oh the steering wheel, or by the accelerator, without drilling and tapping the inlet pipe, and fixing an additional stop-tap or valve,

together with some form of adjustable rod, between the stop-tap and throttle-lever or accelerator.

The stop-tap (I in. iron) is of course required, and in our case is placed opposite the driver, within reach of his right hand. By means of this tap, the quantity of gas to the engine may be checked, and the tap can be closed when going down hill or standing still. The suction of the engine is sufficient to empty the holder right out. If the main tap is left open when the motor is standing," the gas escapes, though I understand that the motors with large holders do not do this. In fact, such might easily be assumed, as the large area of the holder would tend to prevent the escape of gas through a pipe at a lower level than the container. [There would be a delivery pressure after a certain stage of deflation.—En.] On the next motor I fit up, I propose to take the gas connection through the extreme back of the holder. My reason for this is that when the motors are travelling the gas is all pressed to the back of the holder—that is if the container is half empty. When the motor is standing the bag is level, but as soon as the motor moves the bag heaps up at the back, and the .gas fails to reach the engine.

A point that future users should be warned against is letting the holders be strained. I find that both of ours leak somewhat, due to this cause. The valve I use, which is a modified form of. Mr. Barton's, was made at the local tinsmith's, and for safety's sake I think they should all be provided with a catch, as shown in the photograph of the valve submitted to you on a former decasion.—Yours faithfully, (Signed) PERCY DOUGALL.

We have to thank Mr. Dougall for the sketch from which we were able to prepare the accompanying illustration, and we would remind our readers that there is, on the brass or copper tube through which the coal-gas is led from the gas-holder, an ordinary gas-cock (stop tap), to enable the driver to shut off the gas completely when the engine is stopped, or to check the flow for a light engine-load.

Gas Outlet Best at Back of Holder.

It is particularly interesting to observe Mr. Dougall's experience in respect of the best point in the flexible gas-holder at which to fit the connection to lead the gas to the engine. He strongly favours the back of the holder, for the reasons which he states. This conclusion is but indicative of detail improvements for which we look.