With Intent to Improve.

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

A Weekly Summary of Recent Patents, of Interest to the Maker and User 'of Commercial Motor Vehicles,

Selected and Abridged by H. S. Hall, A.M.I.A.E.

A Lynton When with Collapsible Rim.

It is surprising, considering its manifest disadvantages, and the need for expensive machinery for its manipulation, how long the pressed-on solid band tire has remained with us in its present form, without there being any really determined attempt to replace the, pressing-on process by some simpler one, which need not necessarily call for mechanical aid.

In the States, the detachable or demountable tire has long been in use. It is specified in the • American 'W.D. specification, so that we may safely assume that, in some form or other, it has preyed to be capable of rendering satisfactory service.

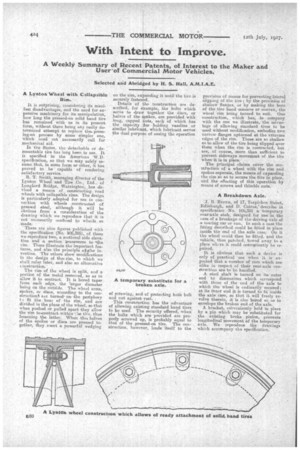

IL T. Smith, managing director of the Lynton Wheel. and Tire Co., Ltd.. of Longford Bridge, Warrington, has devised a means of constructing_ road wheels with collapsible rims. The design is particularly adapted for use in connection with wheels constructed. of pressed steel, althouali it will be obvious from a consideration of the drawing which we reproduce that it is not necessarily confined tie wheels so made.

-There are nine figures published with the specification (No. 106,385), of these we reproduce two, a sectional side elevation and 44 section aransverse to •-tilie rim. These illustrate the important features, and also the principle ofir-lle invention. The others show modifications in the design of that rim, to Which we shall refer later, and also an alternative

enstriiction. . .

The rim of the wheel is split, and a portion of the metal removed, BO as to allow it to contract. It is bored taper from each edge, the larger diameter being On the outside. The wheel arms, spokes, or discs, according to the construction sic turned-. on -the periphery t3 fit the base of the rim, and ore divided in the plane of the wheel, so that when pushed or .pulled apart they allow the rim to.controct within '711e tire, thus loosening the latter. When the, halves of the spokes or discs are pressed together,. they erit a powerful wedging

on the rim, expanding it until the tire is securely fastened. Details of the construction are described, for eXample, the bolts which serve to dravt together the discs, or halves of the apekes, are provided with long, capped nuts, each of which has the capacity for holding vaseline or similar lubricant, which lubricant serves the dual purpo e of easing the operation of screwing, and of protecting both bolt and nut against. rust.

This construction has the advantage of allowing existing standard band tires to be used. The security offered, when the bolts which are provided are properly screwed up, is probably equal to that of the pressed-on tire. The construction, however, lends itself to the provision of means for preventing lateral slipping of the tile; by the provision of shallow flanges, or by making the born of the ,tire band concave or convex, the wheel rim being turned to snit. One construction, which has, in company with the one we illustrate, the advantage of allowing standard tires to be used without modification, embodies two narrow flanges upturned at the extreme edges of the rim. These are so shallow as to allow of the tire being slipped ever them when the rim is contracted, but are, of course, more than sufficient to prevent sideways movement of the-tire when it is in place. The principal claims cover the construction of a wheel with the rim and spokes ,separate, the means of expanding the rim so as to secure the tire in place, and the effecting of this operation by means of screws and thimble nuts.

A Breakdown Axle.

J. B. Brown, of 17, 'forpichen Street, Edinburgh, and D. Cairns, describe in

specification No. 106,381 a temporary rear-axle stub, designed for use in the case of a breakage of the driving axle of a touring car or van. In such a case the fitting described could be fitted in place inside the end of the axle case. On it the wheel could then be 'fitted, and the vehicle, thus patched, towed away to a place where it could conveniently be repaired. It is obvious that such a device is only of practical use when it is ex pected that a number of cars which are alike in respect of their rear-axle construction are to be handled.

A steel shaft is turned on its outer end to dimensions which correspond with those of the end of the axle to which the wheel is ordinarily secured; at its inner end it is turned to fit inside the axle case, se that it will freely re-. verve therein, it is also bored so as to envelope the broken end of the axle.

A bracket, conveniently held in place by a pin which may be substituted for the existing brake pinion, prevents longitudinal movement of the temporary axle. We reproduce the drawings which accompany the specification.