road and

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

workshop by Handyman

Bench wise.'

repair risks (7)

INSTANCES where a repair job has been put up wrong in some way and therefore has to be pulled apart again for correction are more frequent than in the past.

I do not mean that a completely wrong assembly was made, but that either fitting experience was missing, or a standard trick of the trade was overlooked. The reason may possibly be a combination of more haste, less speed, and the fact that there are now fewer older fitters to be found with the experience to spot these faults. Incentive schemes, too, can bring these situations in their train.

Regular delay I want at first to draw attention to one quite regular delay in engine assembly usually suffered by the younger or lesser experienced mechanic who does not unfortunately always learn the lesson.

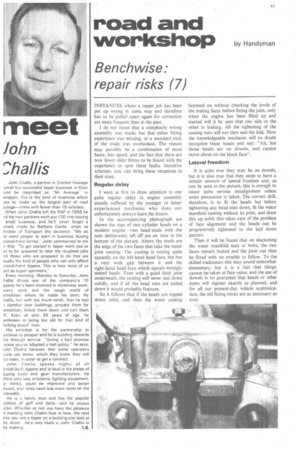

In the accompanying photograph are shown the tops of two cylinder heads on a modern engine—two head-studs with the nuts deliberately left off are on view in the bottom of the picture. Above the studs are the edge of the two faces that take the water joint casting. The casting is resting quite squarely on the left-hand head face, hut has a very wide gap between it and the right-hand head face which signals wrongly seated heads. Even with a good thick joint underneath, the casting will never seal down solidly, and if all the head nuts are pulled down it would probably fracture.

So it follows that if the heads are nipped down solid, and then the water casting fastened on without checking the levels of the mating faces before fitting the joint, only when the engine has been filled up and started will it be seen that one side or the other is leaking. All the tightening of the casting nuts will not then seal the leak. Now the knowledgeable mechanic will no doubt recognize these heads and say: "Ah, but those heads are on dowels, and cannot move about on the block face".

Lateral freedom It is quite true they may be on dowels, but it is also true that they seem to have a certain amount of lateral freedom and, as can be seen in the picture, this is enough to cause quite serious misalignment unless some precaution is taken. The correct drill, therefore, is to fit the heads but before tightening any head nuts down, fit the water manifold casting without its joint, and draw this up solid; this takes care of the problem of face alignment and the heads can be progressively tightened to the laid down pattern.

Then it will be found that on slackening the water manifold nuts or bolts, the two faces remain butted and the joint can then be fitted with no trouble to follow. To the skilled tradesman this may sound somewhat elementary, but it is a fact that things cannot be taken at face value, and the use of dowels is no guarantee that heads or other items will register exactly as planned, and for all our present-day vehicle sophistication, the old fitting tricks are as necessary as ever.