SOME INGENIOUS ENGINE REPAIRS.

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Work Carried Out by Our Driver and Methanic Readers.

INTERESTING if somewhat lengthy letter from "

IvYbridge, deals with miscellaneous re pairs to engine parts, and we award him the 15s. prize this week. He concerns himself, as a matter of fact, with those jobs which are likely to be found necessary when an engine has to be overhauled.

Dealing -first with the bearings. He suggests that the first thing to do is to pay attention tee: the journals of the crankshaft, making sure that they are all right before any attempt is made to fit bearings to them. As a preliminary, therefore, calliper each journal, or, better still, micrometer them, to make sure that they are round. If slightly oval, they can, with care, be put right by the use of a fine file and emery cloth. Having got so far, attention should be turned to the bearings. If the wear on these is not more than 1-32 in-., that is to say, if the difference in diameter between the trued-up journals and the interior of the bearings is not more than 1-32 in., the matter can be set right simply by filing the butts of the halfbearings and letting them together. In such circumstances, each pair of bearings must -be fitted to its journal, scraping out unnecessary metal with the aid of a proper scraper, until good contact is made ever about two-thirds of the surface. It is not necessary that this contact should exist at the joints of the bearings. If, when the bearings have been bedded down to this extent, the crankshaft can be turned easily when the bearings caps are screwed down tightly, it can be considered that a satisfactory job has been, made of this part of the overhaul.

The big-ends of the connecting rods should be treated in ,exactly the 'same way, and if the diffesenee in diameter between journal and bearings is more than 1-32 in., it will be necessary either to reline or renew the bearings according to whether they are white-metallined or not.

Next assemble the crankshaft in its case and examine the timing wheels, replacing any which happen to be badly worn, and paying particular attention to the condition of . the keys. Make sure that the timing wheel on the erankghaft does nat. mesh too deeply with the others. If it does, the cause is most likely that the shaft has been bedded to deeply into its bearing. To remedy this it .will -be necessary to pack the bearing itself away from the case, making

use of shims for the purpose. Next inspect the iiistons, fitting new gudgeon pins or new bushes if required; this is necessary if there is the least amount of vertical movement possible between the pin, piston and connecting rod.

It is advisable to renew all the piston rings when overhauling. These should be _fitted into the cylinder before they are put on to the piston. They are correctly fitted when the distance between the ends is 1-64 in. after the sings are -placed iii .the cylinder. Before refitting the rings, inspect the grooves in the ,.pistons. If ridges have formed they must he _turned out. If the rings are too wide they can be rubbed dawn on a piece of fine emery cloth.

New fit the pistons on to the connecting rods and erect the latter 'on the crankshaft. Test the pistons for uprightness and set them right in this eons pection before proceeding any farther.

.Inspect the valves and guides, replacing any` that may he worn, grind in the former, taking care to remove all traces of grinding-paste before re-erecting.

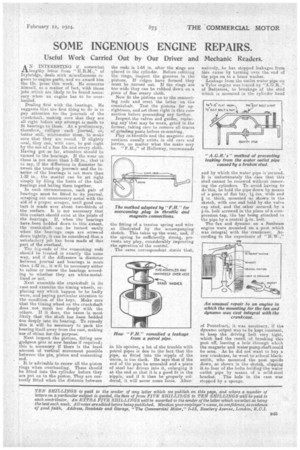

Play in throttle-and the magneto connections -usually exists in old cars and lorries, no matter what the make may be. "F.H.," of Holloway, recommends

the fatting of a tension spring and wire as illustrated by the accompanying• sketch. This takes -up the wear, and, if the spring be sufficiently strong, prevents any play,. considerably improving the operation of the control.

-The same correspondent .states that, in his opinion, a lot of the trouble with petrol pipes is due to the fact that the pipe, as fitted into the nipple of the union, is too slack. He says that if the end of the pipe be annealed and a piece of steel bar driven into it, enlarging it at the end so that it is a good fit in the nipple, and if it then he properly soldered, it will never come loose.

natively, be has stopped leakages from this cause by turning over the end of the pipe on to a brass washer. 'Leakage from the outlet water pipe on e Tyler engine was traced by "A.G.R.," of Battersea, to breakage of the stud which is mounted in the cylinder :head

and by which the water pipe is secured. It is unfortunately the case that this stud cannot be renewed without removing the cylinders. To avoid having to do this, he held the pipe down by means of a piece of flat bar, 1 ins, wide and g in, thick, mounted sas shown in the sketch, with one end held by the valve cap stud, and the other secured by a bolt screwed in the place of a compression tap, the bar being attached to the pipe by a central jr-f-in. bolt.

The fan and dynamo on a Sunbeam engine were mounted on a post which was integral with the crankcase. According to the experience of "H.W.,"

of Pontefract, it was necessary, if the dynamo output was to be kept conStant, to keep the driving belt very tight, which -had the result of breaking this post off, leaving a hole through which the magneto and water pump shaft could be seen. As be did not want to buy a new crankcase, he went to arlocal blacksmith, who mounted the post upside down, as shown in the sketch, clipping it to four of the bolts holding the water outlet pipe by means of a mild-steel bracket. The hole in the case was stopped by a sponge.