Light Up Your Lamps At 6.6 on Thursday ; 6.7

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

on Friday ; 6.9 on Saturday ; 6.12 on Monday ; 6.15 on Tuesday ; 6.17 on Wednesday.

This Valve-seating Tool Will Take Various-Sized Cutters.

[1438] " A.H. H." (Llandaff) wiites :—" I have noticed in your '1). and M.' pages many interesting methods adopted by various mechanics for truing up valve-seatings whilst the cylinders are in position. The various devices utilized, however, have been suitable for one size of valve only. I enclose a description and sketch [We have had this redrawn.—ED.1 of a tool 1 recently constructed myself, which enables me to reseat any size of mushroom-valve.

" The main body of the tool I made out of a piece of I in. round steel, skimmed up in the lathe to the shape shoixn. I then drilled a in. tapping hole, in. deep, dead in the centre at the bottom portion, and afterwards tapped it out a in. Whitworth. To enable inc to revolve the tool, I drilled a in. hole in the

top portion and pushed in a piece of in. steel bar and tightened it up with a small set screw.

" It now remained to make a seating for placing in cutters of various sizes, and to do this I filed out a. rectangular hole in. by in. through the base oi= the body, and, to lock the piece of tool-steel in position for facing the valve-s,eats T. put in a in Whitworth set screw. It was necessary, in order to ensure the seats being faced true, Mr the device to be provided with a spigot at the base to act as a guide. " For this purpose, I obtained a. piece of in, round steel and turned it down to the bore of the valvestem guide, and, with a in. thread turned down to the collar, I was enabled to screw this spigot into the body of the tool, and thus the cutter was always kept in the correct position during operations.

"With a few various sized cutters in stock and D4

dummy stems turned to different diameters, I am able to reface any size valve-seating."

Renewing a Tractor's Steam-chest Face.

[1439] " H.Del." (West Bromwich) writes :—" One day recently a tractor was brought in for repairs and general overhaul. It had been in service a considerable length of time, and we were told to make a good job of it. When we came to examine the steam-chest, it was found that its face was so much corroded— probably owing to a great extent to the use of indifferent feed water—that it was decided not to send out the machine in this unsatisfactory state. "We did not, however, order replace castings Rhthe cylinders, as this would have run up the cost very considerably, and after a. little consideration it was decided to fit the valve chest with a new facing. The sketch I enclose We have had this redrawn.—ED,] shows the repair.

" The corroded face of the casting was first planed to a depth of in., and then again planed with a recess to an additional depth of :L in. We made a false face out of gunmetal, the various ports being

carefully cut to templet. The finished thickness of the plate was ie in., so that there was little difficulty in cutting in the ports. The new face was placed in the recess and fixed in position by means of a. plentiful supply of Delta. Metal set-pins, made with countersunk heads. That portion of the bar which was utilized to turn the pins on the lathe, was not cut off immediately upon screwing the set-pins, as we wanted metal left with which to se2...ew them home.

"We then tapped the original casting out in. Whitworth where there was sufficient metal, and afterwayds made a templet to enable us to drill and countersink the new gunmetal face to suit the tappings. It only remained now to fit the face in position. We made the joint with red lead and boiled oil, placed the plate in the recess, and screwed in all the set-pins. "When they had been screwed tightly home, the extra metal was cut off and the ends riveted over. The whole face was then skimmed up on the planing machine, and the valve-lace was then. equal to new, and, besides proving highly satisfactory now the engine is in service again, it kept down that repair bill, as new cylinders were not ordered."

How to Sling an Engine.

[1140] " G.W.E." (Thornton Heath) writes :—" wonder how many mechanics, when slinging an engine in order to transport it from the overhaul bench to the chassis, or vice versa, consider the amount of damage that can easily be done by not paying particular attention to the manner in which the unit is slung " I have often noticed that in raising an engine from a chassis with blocks and falls, some mechanics arrange the rope in such a manner that, directly the engine is clear from its moorings, the weight of the flywheel causes it to tilt so much that it becomes very difficult to lift it straight out of the frame.

This I have found is principally due to the fact that those who do the slinging are apt to make too free a use of the projecting clutch-shaft and the front nose of the engine for affording a hold to the rope. This puts a strain upon parts designed for much lighter work than that of supporting the whole unit.

" Perhaps my meaning will be more clearly. understood on reference to the enclosed sketches [We have had these redrawn.—EDJ, the left-hancl one shows how not to sling an engine. In the other sketch it will be seen that the rope is placed round the base of the cylinders, near the water jacket ; the position of the rope in such a case allows the engine to he raigied horizontally, thus permitting one to remove the base chamber if necessary whilst the engine is suspended.

" Whenever the lifting tackle can be spared, this is quite a handy way to get at the big-end bearings for making adjustment, and a thorough examination of the principal working parts of the engine can be made from beneath with the greatest convenience. " This method of slinging will no doubt be appreciated by fitters and mechanics who take an interest in the details of repairs and general overhauls."

Inverting a Piston to Stop a Leak in the Cylinder.

The sender of the following communication has been awarded the .10s. prize this week.

[1411] " (Aberdeen) writes :—" A few

weeks ago I was sent out from headquarters to replace a cracked cylinder on a bus, which was stranded some 45 miles distant. On arrival at my destination, I was very much upset to find that the new cylinders (they were cast in pairs) which I had brought with me were not the same as those to be replaced, the difference being in the bore of the water-pipe unions, which would necessitate new nipples being fitted.

" As there was no garage near by where I could procure unions and adapters, I decided to run the vehicle home with the cracked cylinder in place. This found could not be done without ad6pting some method of stopping the leak in the fractured waterjacket, as the water was passing into the crank chamber so rapidly that the radiator soon emptied itself.

" However, upon a little consideration I managed to get over thc:i difficulty. Fortunately for my purpose, the engine was of a type that the connecting rods and pistons could be withdrawn by simply taking off the crankcase inspection covers and uncoupling the big-ends, letting the rods and pistons into the bottom of the engine base and lifting them out at the side door. The engine was also provided with overhead valves, and, by unscrewing a nut, a valve and its seating could be lifted out in one piece.

"To proceed with the operation, I first took out the piston of the damaged cylinder, uncoupled the .connecting rod, afterwards replacing the gudgeon-pin in the piston. I then took out the two valves and valveboxes, which enabled me, with the aid of a flash-lamp, to discover the exact position of the crack, which I found to be directly at the bottom of the water-jacket. Next, I liberally coated the piston with red lead, and getting a piece of soft rope out of the tool kit, teased it out and wound strands of it round the piston.

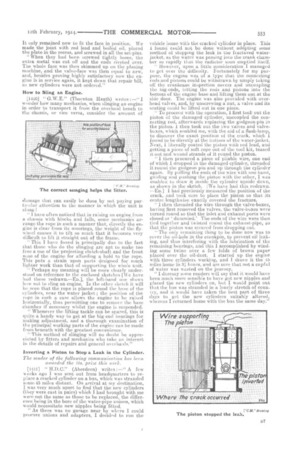

" I then procured a piece of pliable wire, one end of which 1 dropped in the damaged cylinder, threaded it round the gudgeon pin and up through the cylinder again. By pulling the ends of the wire with one band, guiding and pushing the piston with the other, I was enabled to draw it inside the cylinder upside down, as shown in the sketch. [We have had this redrawn. —ED.] I had previously measured the position of the crack, and took care to place the piston so that its centre lengthwise exactly covered the fracture.

I then threaded the wire through the valve-boxes, having .first removed the valves, the valve-boxes were turned round so that the inlet and exhaust ports were closed or dummied.' The ends of the wire were then tied together and twisted round the exhaust-pipe, so that the piston was secured from dropping out.

"The only remaining thing to be done now was to cover the oil-hole in the crankpin, to prevent oil leaking, and thus interfering with the lubrication of the remaining bearings, and this I accomplished by winding some twine over a few folds of brown paper placed over the oil-duct. I started up the engine with three cylinders working, and I drove it the 45 miles home in hours, and am sure that not a cupful of water was wasted on the journey.

" 1 daresay some readers will say that it would have been much more sensible to have got new nipples and placed the new cylinders on, but I would point out that the bus was stranded in a lonely stretch of country, and it would have taken the best part of three days to get the new cylinders suitably altered, whereas I returned home with the bus the same day."