E XPERIENCE with the vast fleet of Bedford vehicles which was

Page 42

Page 43

Page 44

If you've noticed an error in this article please click here to report it so we can fix it.

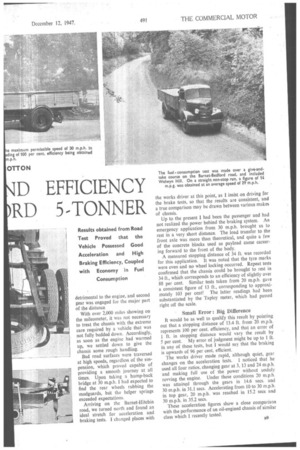

maintained by the Services during the . war, showed that little could be done to the chassis to better its performance. It proved itself to be suitable for operation under many conditions of climate or terrain, and all that was required to make it appropriate for peace-time use was to clean up the appearance of the radiator and bonnet covers.

Some slight chassis and engine modifications have, however, been made, including improved exhaust-valve cooling, redesigned fuel pump and distributor, and coldsqueeze riveted frame members, these being better able to withstand the loosening effects of heavy service.

The Bedford 5-ton long-wheelbase chassis is so well known that there is little left to describe that is not already generally knoWn. The six-cylindered petrol

engine has been tuned up to develop 72 b.h.p. at 3,000 r.p.n-t , with a maximum torque of 161 lb./ft. at 1,200 r.p.m. Transmission is carried through a 10-in, singleplate clutch, four-speed gearbox and open propeller shafts to the straddle-mounted pinion drive of the fully floating rear axle. Constant-mesh gears are fitted to second, third and fourth speeds of the gearbox.

Dewandre-Lockheed Brakes

The vacuum-assisted hydraulic brake system employs a tandem master cylinder, which ensures that braking effort is applied to the front or rear wheels even if either of the brake lines be severed or damaged. Progressive braking is obtained by using bisector expander units on the rear axle. All shoes fore and aft are linked to give a servo action. Reverse-camber springing is employed at the rear, in addition to which heavy-duty helper springs are standardized. It is claimed that the shotpeened rear main-spring leates give longer life under heavy service, and increase resistance to fatigue.

With semi-forward control, the engine is partly located under the bonnet and half in the cab. Quickly detachable panels in the cab provide access to the sear of the engine, which can be withdrawn without removing the cab.

Modified to assist in easy servicing, the inlet-valve

seat of the fuel pump can be removed and changed without disturbing the top pump assembly, and the valveseating assemblies are interchangeable. A large-orifice engine-oil filler

is now standardized and incorporates an air filter which removes all dust and impurities from the air entering the crankcase in the normal system of ventilation.

It was no strange sensation to be travelling in a Bedford, with the exception that the payload was over 5 tons, which tended to make acceleration a 'trifle slower than that to which I had been accustomed in earlier times.

Starting the test from Vauxhall Works, Luton, we began the long climb towards St. Albans. The stiffish gradient caused marked detonation in the engine in third gear, and, although the hill might have taken in that gear, it would have been

detrimental to the engine, and second gear was engaged for the major part of the distance.

With over 2,000 miles showing on the mileometer, it was not necessary to treat the chassis with the extreme care required by a vehicle that was not fully bedded down. Accordingly, as soon as the engine had warmed up, we settled down to give the chassis some rough handling.

Bad road surfaces were traversed at high speeds, regardless of the suspension, which proved capable of providing a smooth journey at all times. Upon taking a hump-back bridge at 30 m.p.h. I had expected to find the rear wheels rubbing the mudguards, btit the helper springs exceeded expectations.

Arriving on the Barnet-Hitchin road, we turned north and found an ideal stretch for acceleration and braking tests. I changed places with the works driver at this point, as I insist on driving for the brake tests, so that the results are consistent, and a true comparison may be drawn between various makes of chassis.

Up to the present I had been the passenger and had not realized the power behind the braking system. An emergency application from 30 m.p.h. brought us to rest in a very short distance. The load transfer to the front axle was more than theoretical, and quite a few of the concrete blocks used as payload came career ing forward to the front of the body.

A measured stopping distance of 34 ft. was recorded for this application. It was noted that the tyre marks were even and no wheel locking occurred. Repeat tests confirmed that the chassis could be brought to rest in 34 ft., which corresponds to an efficiency of slightly over 88 per cent. Similar tests taken from 20 m.p.h. gave a consistent figure of 13 ft., corresponding to approximately 103 per cent? The latter readings had been substantiated by the Tapley meter, which had passed right off the scale.

Small Error : Big Difference

It would be as well to qualify this result by pointing out that a stopping distance of 13.4 ft. from 20 m.p.h. represents 100 per cent. efficiency, and that an error of 1 ft. in stopping distance would vary the result by 5 per cent. My error of judgment might be up to 1 ft. in any of these tests, but I would say that the braking is upwards of 96 per cent. efficient.

The works driver made rapid, although quiet, gear changes on the acceleration tests. I noticed that he used all four ratios, changing gear at 3, 13 and 24 m.p.h. and making full use of the power without unduly revving the engine. Under these conditions 20 m.p.h. was attained through the gears in 14.6 secs. and 30 m.p.h. in 31.1 secs. Accelerating from 10 to 30 m.p.h. in top gear, 20 m.p.h. was reached in 15.2 secs and 30 m.p.h. in 35.2 secs.

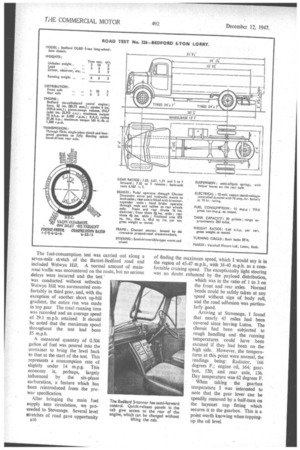

These acceleration figures show a close comparison with the performance of an oil-engined chassis of similar class which I recently tested. The fuel-consumption test was carried out along a seven-mile stretch of the Barnet-Bedford road and included Welwyn Hill. A normal amount of mainroad traffic was encountered on the route, but no serious delays were incurred and the test' was conducted without setbacks. Welwyn Hill was surmounted comfortably in third gear, and, with the exception of another short up-hill gradient, the entire run was made in top gear The total running time was recorded and an average speed of 29.1 m.p.h. attained. It should be noted that the maximum speed throughout the test had been 35 m_p.h.

A measured quantity of 0.506 gallon of fuel was poured into the container to bring the level back to that at the start of the test. This represents a consumption rate of slightly under 14 m.p.g. This economy is, perhaps, largely influenced by the six-phase carburation, a feature which has been reintroduced from the prewar specification.

After bringing the main fuel supply into circulation, we proceeded to Stevenage. Several level stretches of road gave opportunity of finding the maximum speed, which I would say is in the region of 45-47 m.p.h., with 38-40 m.p.h. as a comfortable cruising speed. The exceptionally light steering no doubt enhanced by the payload distribution, which was in the ratio of 1 to 3 on the front and rear axles. Normal bends could be safely taken at any speed without sign of body roll, and the road adhesion was particularly good. was Arriving at Stevenage, I found that nearly 45 miles had been covered since leaving Luton. The chassis had been subjected to rough handling and the running temperatures could have been excused if they had been on the high side. However, the temperatures at this point were normal, the readings being: Radiator, •166 degrees F.; engine oil, 1-64; gearbox, 120; and rear axle, 136. Day temperature was 62 degrees F.

When taking the gearbox temperature I was interested to note that the gear lever can be speedily removed by a half-turn on the bayonet cap fitting which secures it to the gearbox. This is a point worth knowing when toppingup the oil level.