SIMPLIFYING THE LIVESTOCK LOADING PROBLEM

Page 46

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

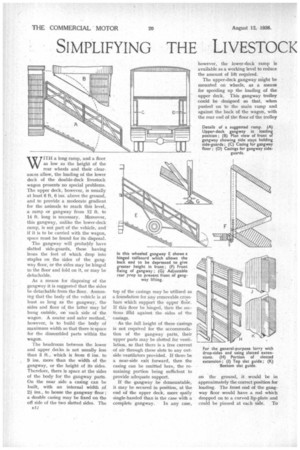

WITH a long ramp, and a floor as low as the height of the rear wheels and their clearances allow, the loading of the lower deck of the double-deck livestock wagon presents no special problems. The upper deck, however, is usually at least 6 ft. 6 ins, above the ground, and to provide a moderate gradient for the animals to reach -this level, a ramp or gangway from 12 ft. to 14 ft. long is necessary. Moreover, this gangway, unlike the lower-deck ramp, is not part of the vehicle, and if it is to be carried with the wagon, space must be found for its disposal.

The gangway will probably have slatted side-guards, these having irons the feet of which drop into staples on the sides of the gangway floor, or the sides may be hinged to the floor and fold on it, or may be detachable.

As a means for disposing of the gangway it is suggested that the sides be detachable from the floor. Assuming that the body of the vehicle is at least as long as the gangway, the sides and floor of, the latter may bif hung outside, on each side of the wagon. A neater and safer method, however, is to build the body of maximum width so that there is space for the dissembled parts within the wagon.

The headroom between the lower and upper decks is not usually less than 3 ft., which is from 6 ins. to 9 ins, more than the width of the gangway, or the height of its sides. Therefore, there is space at the sides of the body for the gangway parts. On the near side a casing can be built, with an internal width of 2-i ins., to house the gangway floor ; a doable casing may be fixed on the off side of the two slatted sides. The top of the casings may be utilized as a foundation for any removable crossbars which support the upper floor. If this floor be hinged, then the sections fbld against the sides of the casings.

As the fail height of these casings is not required for the accommoda tion of the gangway parts, their upper parts may be slotted for venti lation, so that there is a free current of air through these slots to any outside ventilators provided_ If there be a near-side exit forward, then the casing can be omitted here, the remaining portion being sufficient to provide adequate support.

If the gangway be demountable, it may be secured in position, at the end of the upper deck, more eta.sily single-handed than is the case with a

complete gangway. In any case, however, the lower-deck ramp is available as a working level to reduce the amount of lift required.

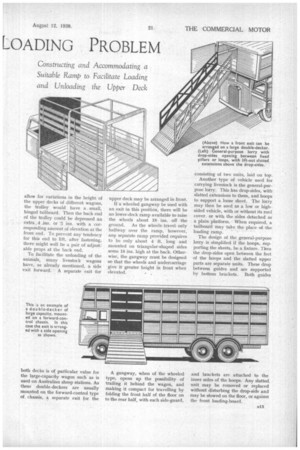

The upper-deck gangway might be mounted on wheels, as a means for speeding up the loading of the upper deck. This gangway trolley could be designed so that, when pushed on to the main ramp and against the back of the wagon, with the rear end of the floor of the trolley

on the ground, it would be in approximately the correct position for loading. The front end of the gangway floor would have a rod which dropped on to a curved lip-plate and could be pinned at each side. To allow for variations in the height of the upper decks of different wagons, the trolley would have a small, hinged tailboard. Then the back end of the trolley could be depressed an extra A ins. or -5 ins, with a corresponding amount of elevation at the front end. To prevent any tendency for this end to lift, after fastening, there might well be a pair of adjust.: able props at the back end.

To facilitate the unloading of the animals, many livestock wagons have, as already mentioned, a side -exit forward. A separate exit for both decks is of particular value for the large-capacity wagon such as is used on Australian sheep stations. As these double-deckers are usually mounted on the forward-control type of chassis, a separate exit for the upper deck may be arranged in front.

If a wheeled gangway be used with an exit in this position, there will be no lower-deck ramp available to raise the wheels about 18 ins. off the ground. As the wheels travel only halfway over the ramp, however, any separate ramp provided requires to be only about 4 ft. long and mounted on triangular-shaped sides some 18 ins, high at the back. Otherwise, the gangway must be designed so that the wheels and undercarriage give it greater height in front when elevated. • A gangway, when of the wheeled type, opens up the possibility of trailing it behind the wagon, and making it compact for travelling by folding the front half of the floor on to the rear half, with each side-guard, consisting of two units, laid on top.

Another type of vehicle used for carrying livestock is the general-purpose lorry. This has drop-sides, with slatted extensions to them, and hoops to support a loose sheet. The lorry may then be used as a low or highsided vehicle, with or without its roof cover, or with the sides detached as a plain platform. When required, a tailboard may take the place of the loading ramp.

The design of the general-purpose lorry is simplified if the hoops, supporting the sheets, be a fixture. Then the drop-sides open between the feet of the hoops and the slatted upper parts are separate units. These drop between guides and are supported by bottom brackets. Both guides and brackets are attached to the inner sides of the hoops. Any slatted. unit may be removed or replaced without disturbing the drop-side and may be stowed on the floor, or against the front loading-board.