TRACTORS FOR THE LINCOLN TRIALS. •

Page 16

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

The Main Features, of the Saunderson, Moline and Overtime Models and Eros Attachment.

THERE IS AS LITTLE need for us to question Mr. Saunderson as to the reasons which led to the present design of1Saunderson tractor as there is for us to explain them to the majority of our readers. They art too well known. It may, however be worth while to mention in passing that it is the result of 23 years' continuoas experience, during which time almost every method of construction known has been put upon trial. This fact is amply demonstrated by a series of photographs which are reproduced in the new catalogue just issued by the company. It will be seen that in 1904, which is the earliest year of which apparently, records exist, the machine was a two-wheeled one, and required the addition of an implement of some sort to enable it to be moved. Even at that. time, however, and apparently continuously since, the idea of making the machine an all-round one and of universal application, had been conceived, as one of the reproductIons shows it hauling a large portable steam engine, and it is also depicted ploughing, harvesting, mowing, etc. A little later on a third wheel was added, and it is interesting to note that in 1907 all. the three wheels were driven.

The present model, as, of course' is fairly wellknown, is the one which was selected by the Government for use in the ploughin-g scheme during the war. It is known as Model G. and is of 23-25 h.p. In order to increase its accessibility, and incidentally to facilitate manufacturing operations, what may be termed unit construction has been adopted. A substantial frame of channel steel carries upon it from front to rear, in the order named, the radiator, engine, and gearbox. They are all so positioned that any one can readilY be removed and replaced without disturbing the others. Accessibility to the engine in particular is facilitated by carrying the radiator on trunnions, so that, by uncoupling the water pipes, it can be tilted away from the engine, making the latter particularly

easy to get at. .

The power unit is a two-cylinder vertical engine, especially designed to consume paraffin as a fuel. The engine is started on petrol, and as soon as warm turned over to the heavier fuel, which is vaporized by exhaust heat in a special chamber, with provision for regulating the amount of heat according to requite ments. This part of the machine has been a subject

of special study, and is remarkably efficient. The .vaporizer to be fitted on the trials tractor is a new type, not hitherto used and of which no details may yet be published. The clutch is a leather-lined cone, and the drive thence is transmitted to the gearbox by a first reduction of plain spur wheels. The box itself is of simple construction, ordinary motorcar type, the gears sliding into mesh, a particular feature, being the provision of plain bearings of ample diameter and length. The final transmission is by spurs to a sturdy bevel differential gear an the rear axle, for which gear a locking mechanism is fitted.

Mention should be made of an extremely important feature of this tractor, the provision of a winding drum, which is rendered operative by removing the driving pins from the nearside rear road wheel, leaving the differential gear free, so that the power is transmitted direct to the drum, which is bolted thereto Briefly, the capacity of this tractor is catalogued -as follows:—Drawbar pull, 3,000.1b. ; winding drum pull, roughly three times that of the drawbar ; -haulage capacity, from five to six tons. It will plough three-quarters of an acre per hour, or drive a fallsized threshing machine.

The following are the principal dimensions: Engine, two cylinders, ai in, bore by 8 in. stroke ; gearbox, three speeds and reverse of two, three, five, and three miles per hour respectively ; the belt pulley is 12 ins, diameter and 7 ins, wide, andis coupled direct to the engine, running normally at 750 apau. ; the rear road wheels are 4 ft. diameter and 10 ins. wide ; the front, 2 ft. 6 ins, diameter and 6 ins. wide. Pro. vision for towing is made both front and rear, and the front axle is centrally pivoted so as to allow complete freedom of movement in a vertical plane. Incidentally, it should be noted that the front wheels are independently sprung. A tractor which presents many features of great interest is the Moline Universal. The steering gear is of very curious design, the whole front portion of the tractor swivels on the rear portion and is eon, trolled by a small pinion which meshes with a sector almost as wide as the frame.

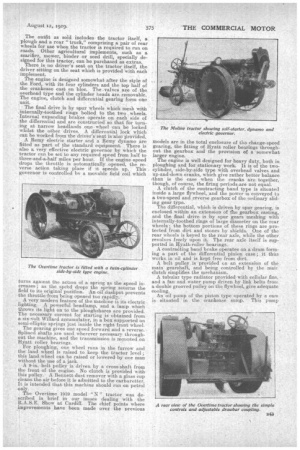

The machine really epnsists of a complete power unit carried on two large diameter driving wheels.; to the back of this is pivoted the girder frame to which the various agricultural implements can be bolted, the small wheels of these implements forming the rear wheels-of the whole tractor..- The outfit as sold includes the tractor itself, a plough and a rear " truck," comprising a pair of rear wheels for use when the tractor as required to run on roads. Other agricultural implements, such as a scarifier, mower, binder or seed drill, specially designed for this tractor, can be purchased as extras.

There is no driver's seat on the tractor itself, the driver sitting on the seat which is provided With eaoh • implement.

The engine is designed somewhat after the style of the Ford, with its four cylinders and the top half of the crankcase cast en bloc. The .valves are of the overhead type and the cylinder heads are removable. The engine, dutch and differential gearing form ore . unit. The final drive is by spur wheels which mesh with ,internally-toothed rings bolted to the two . wheels.

• Internal expanding brakes operate on each side of the differential and arc constructed -so that fOr turning at narrow headlands one . wheel can be locked whilst the other drives. A differential lock which can be worked from the`driver's-Seat is also Provided.

A Remy electric starter and a Remy dynamo are fitted as part of the standard equipment. There is also a very effective electric governor by which the tractor can be set to any required speed from half to -three-anct-a-half miles per hour. If the engine speed drops the throttle is automatically opened, the. reverse action taking place if it speeds up. This governor is controlled by a movable field coil which turns against the action of a spring as the speed increases; as the spad drops the spring returns the field to its original position, An oil clashpot prevents the throttle. from being opened too rapidly. A very modern feature of the machine is its electric lighting. A powerful headlamp, and a lamp which tJarow:s its light an to the ploughshares are provided, The necessary current for starting is obtained from a six-volt Willard accumulator, in a box supported on semi-elliptic springs just inside the right front wheel. The gearing gives one speed forward and a. reverse. Splined shafts are used wherever necessary throughout the machine, and the transmission is mounted on Hiatt roller bearings. For ploughing, one wheel runs in the furrow and the land wheel is raised to keep the tractor level ; this land wheel can be raised or lowered by one man without the use of a jack.

A 9-in, belt pulley is driven by a cross-shaft from

• the front of the engine. No clutch is provided withthis pulley. A.Bennett dust remover with a glass "cup clea.ns the air before it is, admitted to the carburetter. It is intended that this machine should run on petrol only.

The Overtime 1919 model "N" tractor was described in brief in our issues dealing with the R.A.S.E. Show at Cardiff. The chief points where improvements have been made over the previous models are in the total enclosure of the change-speed gearing, the fitting of Hyatt roller bearings throughout the gearbox and the provision ef a somewhat larger engine.

The engine is well designed for heavy duty, both in ploughing and for stationary work. It is of the two cylihder, side-byeside type with overhead valves and up-and-down cranks, which give rather better balance 'than is the case when the cranks are together, though, of course; the firing periods-are not equal. A clutch of the contracting band type is situated inside a large flywheel, 'and the power is conveyed to a. two-speed and reverse gearbox of the ordinary sliding-gear type. The differential, which is driven by spur gearing, is enclosed within -an extension of he gearbox casting, and the final drive is :by spur gears meshing with internally-toothed rings of large diameter on the rear wheels; the bottom portions of these rings are pro tected from dirt and stones by shields. One of the rear wheels is keyed to the rear axle, while the other revolves freely upon it. The rear axle itself is supported in Hyatt-roller bearings. A contracting band brake operates on a drum forming a part of the differential pinion case ; it thus works in.. oil and is kept free from dirt. A belt pulley is provided en an extension of the main gearshaft, and being controlled by the maii clutch simplifies the mechanism. A tubular type radiator provided with cellular fins, and a fan-and water pump driven by link belts from a double grooved pulley on the flywheel, give adequate cooling. An oil pump of the piston type operated by a cam is situated in the crankcase sump. This pump delivers oil to sight feed oilers from which the big ends and other important parts are lubricated. The engine speeds are from 400 r.p.m. to 750 r.p.m., 550 being the normal, speed. The front axle is a semi-steel casting with the steel axle shaft running right through it. It is centrally pivoted.

The steering is of the traction-engine type, i.e., worm and wheel and chain, the chain being provided with spring cushions where its ends are attached to the axle.

The engine can run on both petrol and. paraffin, but it is primarily designed to run on paraffin as its usual fuel, a large capacity paraffin tank being mounted over the .front axle.

Commendable attention has been paid throughout the design to accessibility. A large cover is fitted to the gearbox, through which it is quite easy to exa.mine theezeirs and. shafts. In order to change Worn gears 0M-earings, the removal of the top half of the gearbess and differential casing is quite a simple operation. 'The main clutch can be adjusted by turning one nut and without taking it down in any way.

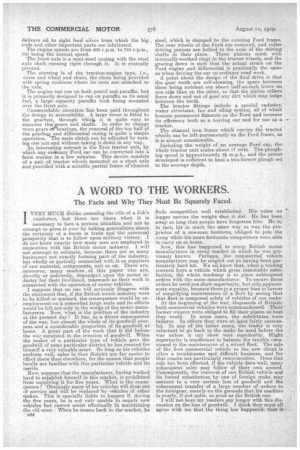

An interesting entrant is the Eros tractor unit, by which any ordinary Ford car can be converted into a farm tractor in a few minutes. This device consists of a pair of tractor wheels mounted on a stout axle and provided with a suitable partial frame or channel , steel, which is clamped to the existing Ford frame. The rear wheels of the Ford are removed, and roller driving pinions are bolted to the ends of the driving shafts in their place. These pinions mesh with internally-toothed rings in the tractor wheels, and the gearing down is such that the actual strain on the Ford engine and differential is practically the same as when driving the ear on ordinary road work. • A point about the design of the final drive is that the gear teeth are self-cleaning, the space between them being notched out about half-an-inch lower on one side than on the other, so that the pinion rollers force down and out of gear any dirt which may ledge between the teeth.

The tractor fittings include a special radiator, water circulator, fan and oiling system, all of which become permanent fitments on the Ford and increase its efficiency both as a touring car' and for use as a • tractor.

The channel iron frame which carries the tractor wheels can be left permanently on the Ford frame, as it is almost unnoticeable.

Including the weight of an average Ford car, the whole tractor unit scales about 17 cwts. The ploughing speed is approximately 2 m.p.h., and the power developed is sufficient to haul a two-furrow plough set to the average depth.