Patents Completed.

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

Crankcase Construction. Roller Bearing Improvements. A Sight-feed Carburetter. Another Spring Wheel.

M. BOVY, No. 2435 of 1914, dated under International Convention, 8th February, 1913.—The accompanying drawings show two sections of a tire in which mechanical springs are used. A strip of india-rubber of semi-circular cross section is fixed inside the tread of the tire. It is formed with a number of recesses, each of which is lined with a metal cup. Conical springs are seated in these cups, and their apices are received on washers mounted on guide pins. The pins are screwed into nipples, which are fixed in the rim of the wheel, and they are adjustable so as to regulate the pressure of the springs. The tire is held in place by the security bolt shown between two of the springs. The plate is wedge-shaped and has fluted side faces, which prevent displacement of the tire when fixing it.

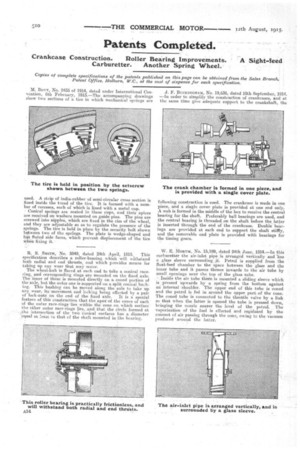

R. S. SMITH, No. 5949, dated 24th April, 1915. This specification describes a roller-bearing . which will withstand both radial and end thrusts, and which provides means for taking up any wear that may occur.

The wheel-hub is flared at each end to take a. conical racering, and corresponding rings, are mounted on the fixed axle. The inner of these is mounted directly on a coned portion of the axle, but the Outer one is 'supported on a Split conical Wring. This bushing can be moved along the axle to take up anv.wear, its-movement and locking being effected by a pair iirlock-nuti on the end of the fixed akle. It is a special feature of this construction that .theapex of_ the cones of each of the outer race-rings-lies within the cone .on. which surface' the other outer race-rings lies, and that the circle formed at .the intersection of the two conical surfaces has a diameter equal at :east to that of the shaft mounted in the bearing.

J. F. BUCKINGHAM, No. 19,636, dated 10th September, 1914. —In order to simplify the construction of crankcases, and at the same time give adequate support to the crankshaft, the following construction is used. The crankcase is made in one piece, and a single cover plate is provided at one end only. A web is formed in the middle of the box to receive the central bearing for the shaft. Preferably ball bearings are used, and the central bearing is threaded on the shaft before the latter is inserted through the end of the crankcase. Double bearings are provided at each end to support the shaft stiffly, and the removable end plate is provided with bearings for the timing gears.

W.-E. Monuxt, No. 15,189, dated 24th June, 1914.—In this carburetter the air-inlet pipe is arranged vertically and has a glass sleeve surrounding, it. Petrol is supplied from the float-feed chamber to thespace between the glass and the inner tube and it passes thence inwards to the air tube by small openings near the top of the glass tube.

• Inside the air tube there is mounted a sliding sleeve which is pressed Upwards by a spring from the bottom against an internal 'shoulder. The upper end of this tube is coned and the petrol is fed in around the tipper parte.of the cone. The coned tube is connected to the throttle valve by a link so that when the latter is opened the tube is pressed down, bringing the nozzle nearer the level of the petrol. . The vaporization of the fuel is effected and regulated by the amount of air passing through the cone, owing to the vacuum produced around the latter.