BMC FJ K140

Page 44

Page 45

Page 46

If you've noticed an error in this article please click here to report it so we can fix it.

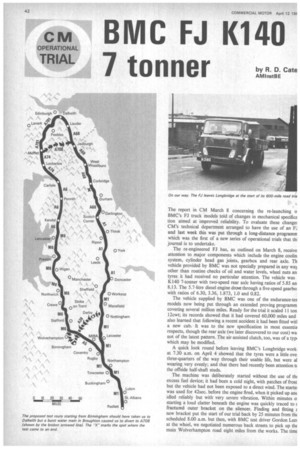

7 tomer by R. D. Cate AMInstBE The report in CM March 8 concerning the re-launching o BMC 's FJ truck models told of changes in mechanical specifics tion aimed at improved reliability. To evaluate these changeE CM's technical department arranged to have the use of an FJ and last week this was put through a long-distance program= which was the first of a new series of operational trials that thi journal is to undertake.

The re-engineered FJ has, as outlined on March 8, receive attention to major components which include the engine coolin system, cylinder head gas joints, gearbox and rear axle. Th vehicle provided by BMC was not specially prepared in any wa) other than routine checks of oil and water levels, wheel nuts an tyres it had received no particular attention. The vehicle was K140 7-tanner with two-speed rear axle having ratios of 5.85 an 8.13. The 5.7-litre diesel engine drove through a five-speed gearbo: with ratios of 6.30, 3.36, 1.873, 1.0 and 0.82.

The vehicle supplied by BMC was one of the endurance-tes models now being put through an extended proving programm covering several million miles. Ready for the trial it scaled 11 ton 12cwt; its records showed that it had covered 60,000 miles and also learned that following a recent accident it had been fitted wit] a new cab. It was to the new specification in most essentia respects, though the rear axle (we later discovered to our cost) wa not of the latest pattern. The air-assisted clutch, too, was of a typi which may be modified.

A quick look round before leaving BMC's Longbridge work: at 7.30 a.m. on April 4 showed that the tyres were a little ove: three-quarters of the way through their usable life, but were al wearing very evenly; and that there had recently been attention tt the offside half-shaft studs.

The machine was deliberately started without the use of tlu excess fuel device; it had been a cold night, with patches of frost but the vehicle had not been exposed to a direct wind. The smite] was used for 42sec. before the engine fired, when it picked up ant idled reliably but with very severe vibration. Within minutes o.

starting a loud clatter beneath the engine was quickly traced to E

fractured outer bracket on the silencer. Finding and fitting z new bracket put the start of our trial back by 25 minutes from th( scheduled 8.00 a.m. but then, with BMC test driver Gordon Lee: at the wheel, we negotiated numerous back streets to pick up thc main Wolverhampton road eight miles from the works. The film

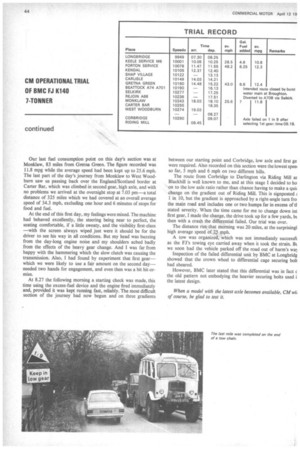

3 8.48 a.m. Our first day's journey was scheduled to take us via Ana Green and Dalkeith to West Woodburn in Northumberd, a total distance of 368 miles. I had decided to drive for the ond leg from Gretna, and my only instruction to Gordon Lees S to get on as fast as possible without exceeding speed limits. Phrough typical 9 a.m. commuter traffic, Wolverhampton was ssed and we joined M6 at Cannock at 9.28. The speedometer v read 9977 and in the first lhr 3min our average speed for miles had been 26.6 mph. Once on M6 I checked the speedoter and odometer, the former being 3 mph slow at 45 mph but odometer accurate. At the Keele service area on M6 I did the t fuel consumption check over the 50 miles from Longbridge 1 the result was 10.8 mpg. The average speed over this section

been 28.5 mph.

From Keele to Forton service station the vehicle was driven at ximutn possible speed over the 77 miles of motorway; average :ed was 48.2 and the fuel consumption a very creditable 12.3 lg.

I noted two particular points on this section: good going ;pite heavy snow, and the slowness of the two-speedaxle anges, while several gear selections had been missed. I noticed it the BMC driver was adopting an unusual clutch technique; appeared to stab at it and release it almost instantaneously tile still in the process of making the gearchange. The system ;med to work well so I made no comment and waited for my .n at the wheel to find the reason for it.

The loaded FJ made light work of Strawberry Bank (winding, n 7) and Shap. On Strawberry it was brought down to second ar, low axle ratio, and the lowest speed recorded was 7 mph. ap was climbed from the Jungle Cafe to the summit in 8min .5 see, the lowest gear being second, high axle, and the lowest eed recorded 12 mph. The ambient temperature was near to :ezing at this point and the engine was working happily away thout any signs of overheating or distress. But the heating and misting equipment called for too much of the driver's attention, pecially when he tried to adjust the unit to defreeze the windreen in a heavy snow shower. The amount of heat available was It enough to clear the screen adequately.

Carlisle was reached in the expected traffic block, which was :rely rather worse than usual. It took us 18min to clear the wn. A wide load and a mechanical road sweeper slowed us on the 11 miles to Gretna, so that a total time of 27min elapsed before our third fuel consumption check point was reached. We had made an average speed of 26.75 mph over this section, the fuel consumption again being excellent at 12.3 mpg.

When I took over at Gretna, it took me only a few seconds to discover the reason for Gordon Lees' clutch technique. This particular unit is at present the subject of a re-designing exercise, and is an air-assisted hydraulic clutch which suffers a considerable delay in operation and tends to be either fully engaged or disengaged. There is virtually no in-between stage and it calls for exceptional attention by the driver if the transmission is not to be punished. After stalling the engine once and making one or two embarrassingly jerky attempts I got the vehicle rolling—while reflecting that I now knew why the gear and axle ratio changes had been missed at times farther back down the road.

Our scheduled route was to have been A74 Gretna to Moffat and then A701 from Moffat via the Devil's Beeftub and Tweedsmuir to Dalkeith. A burst water main at Broughton in Peebleshire had effectively closed our road, however, so I returned to Moffat and chose to run over the A708 via Coppercleuch and Yarrow to Selkirk, where we picked up the Kelso road from which we rejoined our original planned route A68 at St. Boswells. This diversion lopped some 43 miles off our planned route and eliminated a severe gradient in Lasswade.

The going was now beginning to get hard, and the long climb up through Hart Fell and White Coombe saw the exhaust becoming smoky for the first time. The vehicle made extremely good average speeds despite the fact that the road was a new one to me and was not the most suitable for this class of vehicle. But I began to find the constant attention needed for the slow clutch operation a terrible chore; unexpected gradients and bends were uncomfortable to negotiate and I was concerned at the harsh treatment which the transmission was getting. Frequently the slow clutch and indifferent two-speed axle-change mechanism left me between two chosen ratios when the prevailing conditions demanded quick action.

Tidy handling of the vehicle was not helped by a very heavy synchromesh, with baulking mechanism so efficient that the lever movement became hard work when making repeated changes in tough conditions. Although I found it impossible to crash a gear it was also near-impossible to engage some of them on occasion. Our last fuel consumption point on this day's section was at Monlclaw, 83 miles from Gretna Green. The figure recorded was 11.8 mpg while the average speed had been kept up to 25.6 mph. The last part of the day's journey from Monklaw to West Woodburn saw us passing back over the England/Scotland border at Carter Bar, which was climbed in second gear, high axle, and with no problems we arrived at the overnight stop at 7.03 pm--a total distance of 325 miles which we had covered at an overall average speed of 34.3 mph, excluding one hour and 6 minutes of stops for food and fuel.

At the end of this first day, my feelings were mixed. The machine had behaved excellently, the steering being near to perfect, the seating comfortable, if a little sweaty, and the visibility first-class -with the screen always wiped just were it should be for the driver to see his way in all conditions. But my head was buzzing from the day-long engine noise and my shoulders ached badly from the effects of the heavy gear change. And I was far from happy with the hammering which the slow clutch was causing the transmission. Also, I had found by experiment that first gearwhich we were likely to use a fair amount on the second dayneeded two hands for engagement, and even then was a bit hit-ormiss.

At 8.27 the following morning a starting check was made, this time using the excess-fuel device and the engine fired immediately and, provided it was kept running fast, reliably. The most difficult section of the journey had now begun and on three gradients between our starting point and Corbridge, low axle and first ge were required. Also recorded on this section were the lowest spee4 so far, 5 mph and 6 mph on two different hills.

The route from Corbridge to Darlington via Riding Mill at Blackhill is well known to me, and at this stage I decided to ho on to the low axle ratio rather than chance having to make a qui( change on the gradient out of Riding Mill. This is signposted 1 in 10, but the gradient is approached by a right-angle turn fro the main road and includes one or two humps far in excess of tt stated severity. When the time came for me to change down int first gear, I made the change, the drive took up for a few yards, bt then with a crash the differential failed. Our trial was over.

The distance run that morning was 20 miles, at the surprisingl high average speed Of‘,2. mph.

A tow was organized, which was not immediately successfi as the H.'s towing eye carried away when it took the strain. Bt

we soon had the vehicle parked off the road out of harm's wa). Inspection of the failed differential unit by BMC at Longbridg showed that the crown wheel to differential cage securing bolt had sheared.

However, BMC later stated that this differential was in fact c the old pattern not embodying the heavier securing bolts used i the latest design.

When a model with the latest axle becomes available, CM wil of course, be glad to test it.