Less Noise and Accessibility in 3reater N ew Bus

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

By John F. Moon,

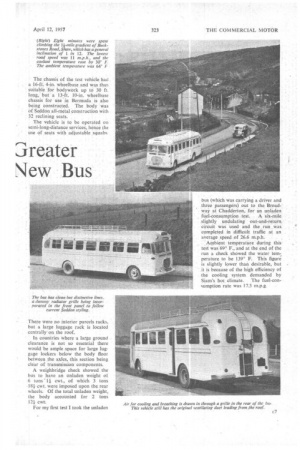

AS announced exclusively in The Commercial Motor on March 15, Seddon Diesel Vehicles, Ltd., are in production with a series of rear-engined passenger chassis to be known as the Mark 18. It is now possible to follow this announcement with an exclusive road-test report of a32-seat bus based on this chassis. This bus is being supplied to Sino-British (Siam),

Ltd., Bangkok. .

The prime feature of this new Seddon design is its simplicity. Rearengined passenger chassis are not new to Britain, but have never met with the full approval of operators who, unlike their contemporaries in many parts of the world, fight shy of somewhat complicated transmission layouts and occasionally reduced engine accessibility.

Neither of these points can be raised in objection to the Seddon Mark 18 chassis. Without exceeding the legal British rear-overhang limits the engine has been placed longitudinally in the frame with the gearbox mounted as a unit with it and driving straight into the back of the axle through a 12-in.-long propeller shaft. There is still room for the radiator to be mounted behind the engine and thus dispense with the need for angled fan drives.

As the engine is supported midway, on a horizontal plane, between the frame side members, good accessibility is given by removing the c6 bonnet, which lies inside the body. It would be as easy to withdraw the complete unit as with the best forward-engined chassis designs.

Despite the use of an indirectinjection oil engine, the rearward mounting of the power unit success fully removes most of the engine noise from the body of the bus and even when sitting alongside the engine its noise did not reach an unacceptable volume at any time.

Originally it was planned that cooling air for the radiator should be drawn in through an intake duct running along the roof of the body, but in practice this was found unnecessary and air is obtained through a conventional -grille in the rear panel of the bus. On the vehicle tested the original cooling duct had not been removed, but good use had been made of it to provide a filtered flow of cool air into the body.

A disadvantage frequently encountered with .rear-engined designs is the difficulty of providing a suitable positive gear-change link age. For this reason many foreign manufacturers have adopted fully automatic transmission in such chassis. The Seddon, therefore, is unique in having a conventional constantmesh unit, and it speaks well for the direct action of the linkage that no difficulty was encountered with gearchanging during the test.

The gear lever is located in the standard remote control section normally used with David Brown gearboxes. This section is connected through a four-piece propeller shaft (which has Hardy Spicer universal joints) to the normal David Brown selector mechanism. Hydraulic clutch actuation is employed.

One of the advantages of rearengined design that immediately springs to mind is that it would permit a much lower floor line than can be obtained with a conventional underfloor-engined chassis. True as this may be, advantage is not always taken of this feature becaiise such an engine layout also allows a good inter-axle ground clearance to be achieved.

This was the prime reason for the evolution of the Seddon design: being intended for Siam, where good roads are rare, a high ground clearance was essential, and was not' obtainable with underfloor-engined chassis. Even so, the laden frame height of the chassis (2 ft. 8+ in. at the front axle) is lower than can be obtained with most underfloor designs. The chassis of the test vehicle had a 16-ft. 4-in, wheelbase and was thus suitable for bodywork up to 30 ft. long, but a 13-ft. 10-in, wheelbase chassis for use in Bermuda is also being constructed. The body was of Seddon all-metal construction with 32 reclining seats.

. The vehicle is to be operated on semi-long-distance services, hence the use of seats with adjustable squabs There were no interior parcels racks, but a large luggage rack is located centrally on the roof.

In countries where .a large ground clearance is not so essential there would be ample space for large luggage lockers below the body floor between the axles, this section being clear of transmission components.

A weighbridge check showed the bus to have an unladen weight of 6 tons 1+ cwt., of which 3 tons -18+ cwt. were imposed upon the rear wheels. Of the total unladen weight, the body accounted for 2 tons 12+ cwt.

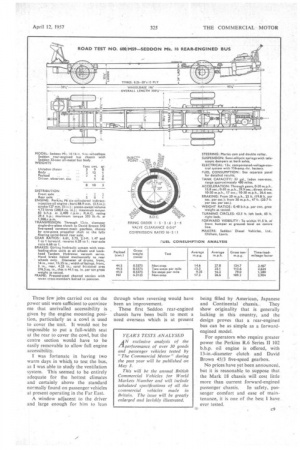

For my first test I took the unladen bus (which was carrying a driver and three passengers) out to the Broadway at Chadderton, for an unladen fuel-consumption test. A six-mile slightly undulating out-and-return, circuit was used and the run was completed in difficult traffic at an average speed of 26.6 m.p.h.

Ambient temperature during this• test was 69° F., and at the end of the run a check showed the water temperature to be 139° F. This figure is slightly lower than desirable, but it is because of the high efficiency of the cooling system demanded by

Siam's hot climate. The fuel-consumption rate was 17.3 m.p.g.

Although the bus was almost empty, the suspension was commendable and no excessive road shocks were conveyed to the body even when running over bumpy roads at more than 40 m.p.h. The engine, which was only lightly loaded, did not become over-noisy at any time, and it was just possible to hear the engine when changing gear. The steering was light and positive, with no trace of tail-end heaviness. The pedals are also light and direct in operation.

Well Loaded

A test load of sacks filled with nails and bolts was then placed in the gangway. The total weight added was 2 tons 44 cwt., equivalent to 36 passengers with light hand-luggage, apart from the three passengers already carried. The .rear wheels carried 1-4 tons of the payload, giving a reasonable inter-axle weight distribution.

Laden fuel-consumption tests were made along the same six-rnile route. and three runs were conducted to establish the consumption rate on non-stop, light-density and heavydensity stage-carriage work. Each stop was of 15 seconds duration, during which time the engine was left idling and the times of the stops were not included in the calculation of average speeds.

At the end of the " six-stops-permile " test, during which the vehicle was being braked at about .2g., an emergency stop from 20 m.p.h. produced a Tapley meter reading of 74 percent., indicating a reduction in efficiency of only 5 per cent. This figure is exceptionally good, particularly as -the bus had covered only 120 miles before my test and the brake facings were not by any means beddedi n.

Reasonable Economy

The fuel-consumption rates obtained show that satisfactory economy under all conditions can be maintained at reasonably high road speeds.

Brake tests were made along a level stretch of the same road and • some good retardation figures were recorded. All the wheels locket! evenly when making "crash " stops from both 20 m.p.h. and 30 m.p.h. and skidding would account for a small percentage of the braking distances attained. The hand-brake performance was slightly disappointing, as the maximum retardation rate obtainable from 20 m.p.h. was 20 per cent.

Tests made along Victoria Avenue, c8 in the same area, revealed that the bus was capable of fair acceleration rates, despite the relatively low powerto-weight ratio. The direct-drive tests made between 10 and 30 m.p.h. showed a consistent acceleration rate. and when pulling away from below 10 m.p.h. there was no indication or transmission roughness.

For the hill-climb test, the bus was taken out to Buckstons Road, Shaw, which is 14 miles long and has a general gradient of 1 in 12, with sections of up to 1 in 64.

Ambient temperature during the climb was 64° F., and the coolant at the foot of the hill registered 148° F., Otis being the normal temperature recorded when running laden.

The climb was made in eight minutes, half of this time being spent in .second gear at two-thirds throttle, when the road speed was 11 m.p.h. The last minute of the climb wasspent in fourth gear at fairly low engine speed, and a temperature check showed an acceptable rise of 30° F.

A second ascent was then made, at the end of which the coolant temperature was 180° F. and the ambient temperature had risen by 1° F.

Starting on 1 in 31

The bus was stopped on the 1-in-64 section and a successful restart in second gear was made. The bottom gear ratio would enable similar starts to be made with ease on 1-in-34 slopes.

A descent of the hill was then made in neutral and I applied the foot brake lightly to keep the speed down to 20 m.p.h. The time of the descent was 44 minutes, and at the foot of the hill a " crash " stop from 20 m.p.h. produced a maximum deceleration rate of .45g. This repre sents a reduction in efficiency of 30 per cent., but it must be •remem.bered that the facings were relatively new.

At the Seddon works I conducted a series of maintenance tests to ascertain the accessibility of the power unit and other major components.

Level checks were made first. It took only 4 seconds to verify the water level, a large filler being located at the rear of the bus. It was necessary to remove the engine cowl (7 seconds) to reach the dipstick, but the stick is not readily accessible and fouls the fuel filter while being removed. With the cowl off I spent 1.1 minutes in checking the engine oil level.

A new type of air cleaner has been evolved for the chassis. consisting of a standard A.C. oil-bath unit enclosed in a shell which has a centrifugal pre-cleaner. It is necessary to remove the cover of the shell first. and there is a long threaded stud securing the main filter cover. Because of the time spent in undoing the nuts, the filter oil level took 14 minutes to check.

There are several traps in the floor to give access to the components. The one immediately ahead of the engine cowl, which has two budget locks, gives access to the gearbox and the selector mechanism and was removed in 21 seconds.

Trap Fouls Seats Farther forward there is a trap over the rear axle which can be lifted in 35 seconds, but it cannot be removed completely because it fouls the seats. In any-case it is necessary to get underneath to check the rearaxle oil level, this job taking 55 seconds.

Opposite the centre entrance there is the battery trap, which takes 8 seconds to remove and 15 seconds to replace. With the trap up I checked the level of the electrolyte in the battery cells in 35 seconds.

At the front of the bus there is a small hinged trap to give access to the brake-fluid reservoir, and including opening and locking the trap, I spent II seconds in verifying the level..

Immediately behind this small trap there is a larger one surrounding the base of the gear lever. This gives access to the forward remote-control box and to the pipe unions of the forward-mounted fuel tank whic,h holds 33 gallons.

While underneath the bus checking the rear-axle oil level, I tested the gearbox-oil level in 43 seconds. Combined filler and level plugs are provided in both these units.

Injectors Accessible

Returning to the inside of the bus. I was able to remove No. 1 fuel injector in 4 seconds and replace it in 65 seconds without any difficulty. All the injectors are equally accessible and, similarly, tappet adjustment should present no difficulty, particularly as provision is made for the use of a starting handle.

The fuel-filter element is bolted 4o the right-hand frame member. adjacent to the fuel-injection pump and, working from above, I removed the element in a minute and 'replaced it in 50 seconds. This job was a little fiddly, but not by any means difficult. Next, I bled the fuel system at the injection pump in 45 seconds. These few jobs carried out on the power unit were sufficient to convince me that unrivalled accessibility is given by the engine mounting position, particularly as a cowl is used to cover the unit. It would not be impossible to put a full-width seat a the rear to cover the cowl, but the centre section would have to be easily removable to allow full engine accessibility.

I was fortunate in having two warm days in which to test the bus, as I was able to study the ventilation system. This seemed to be entirely adequate for the hottest climates and certainly above the standard normally found on passenger vehicles at present operating in the Far East.

A window adjacent to the driver and large enough for him to lean through when reversing would have been an improvement.

These first Seddon rear-engined chassis have been built to meet a need overseas which is at present

being .filled by American, Japanese and Continental chassis.. They show originality that is generally lacking in this country, and the design proves that a rear-engined bus can be as simple as a forwardengined model.

For operators who require greater power the Perkins R.6 Series H 102 b.h.p. oil engine is offered, with 13-in.-diameter clutch and David Brown 45/3 five-speed gearbox.

No prices have yet been announced, but it is reasonable to suppose that the Mark 18 chassis will cost little more than current forward-enginod

passenger chassis. In safety, passenger comfort and ease of maintenance, it is one of the best I have ever tested.