Are your engines ready for the coming freeze?

Page 26

Page 27

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

As Byron reminds us, the English winter ends in July and recommences in August, so it's not too early to consider combating the icy problems that will soon be here. Graham Montgomerie administers some preventive advice

IT COULD BE considered a trifle premature to be talking in September about preventive engine maintenance for winter conditions. However, remembering the total chaos caused by the early cold snap last year with vehicles stranded right across the country, perhaps it is never too early to talk about the fuel system problems which can be caused by waxing-up of the diesel fuel.

Let us go back to first principles and look at just what physically happens to diesel fuel under very cold conditions. To talk of diesel fuel in the singular is rather misleading as it is not one substance but a very complex mixture of hydrocarbons. They all have different boiling points ranging from 170 to 380°C (340 to 720°F) which means that they do not "freeze" at an identical temperature.

Paraffin hydrocarbons have only limited solubility, which in practice means that they tend to form minute wax crystals as the dery cools and these crystals remain in suspension in the fuel. It is the wax crystals which can block the fuel system and cause all the problems.

The colder the ambient temperature, the treater the tendency of the paraffin hydrocarbons to come out of solution as wax. The temperature at which these crystals start to form is officially known as the cloud point. In extreme cases, the temperature can sink low enough to where there is sufficient wax present in crystalline form to physically prevent the fuel from flowing — this temperature is known as the pour point.

Neither of these temperatures, however, can be relied upon to give a precise indication of how a fuel will perform in service, as in most cases the cloud point gives a conservative reading in contrast to the pour point which gives an overstated one. Accord. ingly, a test was developed tc isolate a specific temperature which could then be used to de. fine the low temperature performance of the fuel. This test it known as the cold filter plugging point test, or CFPP for short.

In this test, a measured quantity of fuel is drawn through fine mesh screen. The temperature is gradually lowered and the test repeated until the flow rate through the screen is considerec inadequate. The temperature at which this occurs is thus definec as the cold filter plugging point of the fuel.

Diesel fuel sold in the UK should conform to British Stan. dard 2869 ("Petroleum fuels foi engines and burners") which specifies a CFPP of 9°C (16°F, during the winter and 0°C (32°F for the rest of the year. Where the trouble starts, however, it with the definition of "wintei period".

The oil companies are obviously aware of the problem and take steps to lower the CFPF for winter by incorporating addi. tives which modify the structure of the wax crystals as the fuel cools. These additives do not prevent the waxing but they dc ensure that the crystals art much smaller and thus lest likely to clog up the system. All this does beg the question: "Why don't the oil companiet produce a winter grade fuel all the year round?". The answer is a financial one — additives cost money.

If there was a definite starting point to the winter, at least the oil companies and the operatort would know where they stooc but Mother Nature is not quite so magnanimous. In 1978/79 foi example, the winter was very cold and lasted into mid-April ir northern areas. Last year too with its early December chaos, still fresh in the memory.

Although the oil companies lake arrangements for winter .ade fuel to be in their distribu311 tanks before the freezing eather, it is all too easy for an aerator to be stuck with sumor grade fuel at the wrong rie. In the spring the oil commies switch again and if the Ad weather persists then the immer grade fuel is too early.

Thus thcoil companies have juggle with a number of varia es including the need to make profit and the ability to predict le weather.

Although it thus sounds as lough the remedy lies solely ith the Shells, Mobils and the Ps of this world, this is not so. lore is a great deal that the perator can do to minimise axing problems in his fleet.

The big operator should adger the life out of his fuel

Jpplier to make sure he gets

right fuel for the right condions. This is all very well for the )mpany which buys in bulk, but rr the owner driver who is reant upon the efficiency of his cal filling station it is a difwent story.

There are additives on the iarket, however, which are iailable to everyone and I'll 3me back to these later.

A good starting point for win1r preparation is in the depot :orage tank which by definition nearly always in an exposed art of the yard. Insulating the ipework is therefore highly 'commended. Water and deris inevitably accumulate dur ig the year, whatever precau ons are taken, so they should a removed before the colder

Feather starts. If the tank is tied with a strainer then this hould be of fairly coarse mesh )r. the winter.

Overnight under-cover stows of vehicles is out of the uestion with most fleets but a ood compromise is to keep abides out of the direct wind by arking them nose in to the wall r by erecting a temporary lindbreak.

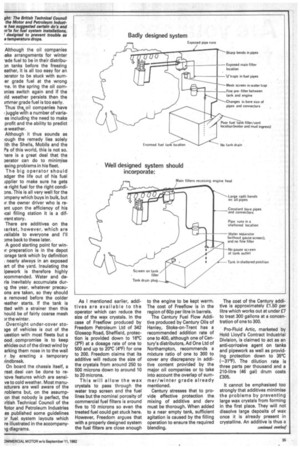

On board the chassis itself, a reat deal can be done to re love features which are sensi ve to cold weather. Most menuicturers are well aware of the roblems but, on the assump on that nobody is perfect, the Iritish Technical Council of the lotor and Petroleum Industries as published some guidelines )r fuel system layouts which re illustrated in the accompanylg diagrams. As I mentioned earlier, additives are available to the operator which can reduce the size of the wax crystals. In the case of Freeflow produced by Freedom Petroleum Ltd of 342 Glossop Road, Sheffield, protection is provided down to 16°C (3°F) at a dosage rate of one to 500 and up to 20°C (4°F) for one to 200. Freedom claims that its additive will reduce the size of the crystals from around 250 to 500 microns down to around 10 to 20 microns.

This will allow the wax crystals to pass through the water trap screen and the fuel lines but the nominal porosity of commercial fuel filters is around five to 10 microns so even the treated fuel could get stuck here. However, Freedom argues that with a properly designed system the fuel filters are close enough to the engine to be kept warm. The cost of Freeflow is in the region of 60p per litre in barrels.

The Century Fuel Flow Additive produced by Century Oils of Hanley, Stoke-on-Trent has a recommended addition rate of one to 400, although one of Century's distributors, Ad One Ltd of Northampton, recommends a mixture ratio of one to 300 to cover any discrepancy in additive content provided by the major oil companies or to take into account the overlap of summer/winter grade already mentioned.

Century stresses that to provide effective protection the mixing of additive and dery must be thorough. When added to a near empty tank, sufficient agitation is caused by the filling operation to ensure the required blending.

The cost of the Century additive is approximately £1.50 per litre which works out at under El-/ to treat 300 gallons at a concentration of one to 300.

Pro-Fluid Artic, marketed by Hold Lloyd's Contract Industrial Division, is claimed to act as an anti-corrosive agent on tanks and pipework as well as providing protection down to 35°C (-31°F). The dilution rate is three parts per thousand and a 210-litre (46 gal) drum costs £305.

It cannot be emphasised too strongly that additives minimise the problems by preventing large wax crystals from forming in the first place. They will not dissolve large deposits of wax once it is already present in crystalline. An additive is thus a case of "prevention rather than cure."

If the system has waxed up, then the offending wax can be eliminated either by physically removing the blockage (not easy if it is in a fuel line) or by warming-up the fuel to dissolve the wax crystals. Neither is recommended early on a cold morning with a ferry to catch.

Gentle heat (with the emphasis on gentle) can be applied using a fan heater or a hair dryer. In no circumstances whatsoever should a naked flame be used.

In-built heaters for the fuel lines are also available, with one such example being Theroline produced by Raychem Ltd o Edison Road, Swindon. This is self-contained self-regulatini heater installed in a heavy dub fuel line which is fitted betweer the primary fuel filter and thr tank. Operated by a -switch or the dashboard, Thermoline claimed to consume less thar two per cent of available batter capacity when used to pre-warn the fuel before a cold start.

Raychem claims that the Ther moline will permit cold start down to-40°C (-104°F). Onci the engine is started, of course it will generate its own heat.

The addition of paraffin or pe trol to diesel fuel is something c a knotty problem because suc an action can incur the disapprc val of the Customs and Excis men. There is no hard and fat ruling on this issue so in cases c extreme urgency — the likel■ hood of a clogged-up fleet fa example, — then the said Cus toms and Excise men can giv permission for paraffin to b added.

However, this should not b taken as carte blanche for ever

operator to add paraffin to hi derv. Permission must be give by Customs and Excise on a individual case basis and there i no guarantee that such permis sion will be forthcoming.

During the cold spell last win ter Daimler-Benz went so far a to recommend the addition of 1 per cent petrol to preven waxing. This pratice is frownes upon by some of D-B's compet tors but the German compan claims that this figure i perfectly safe and that up to 2 per cent is common in th severe conditions of the Scand navian winter.

It must be stressed again the once wax is present in th system then it is too late t1 bother with paraffin or petrol with or without official approval