Complete New Range of Goods Chassis from A.E.C.

Page 90

Page 91

Page 92

Page 95

If you've noticed an error in this article please click here to report it so we can fix it.

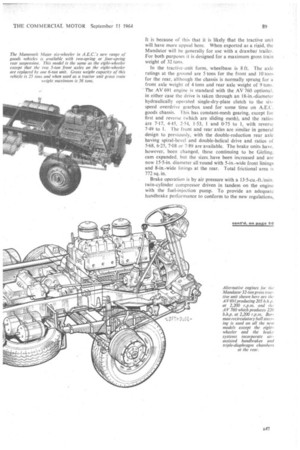

FOLLOWING the announcement last week of new rear-engined p.s.v. chassis, A.E.C. Ltd. has this week announced a complete new range of goods chassis, including Mercury and Mandator four-wheelers, Marshal six-wheelers and Mammoth Major sixand eight-wheelers. The new models all incorporate the redesigned engines described elsewhere in this issue and are specifically designed to take advantage of the increase in gross vehicle weights and dimensions. The eight-wheelers have Marks carrf-and-roller steering, the others having Burman recirculatory ball, and all chassis are designed for a new cab, details of which are not allowed to be released until next week. Model designation departs from the usual A.E.C. practice in that the models do not have a " Mark " number. Instead, the model name followed by the type number of the engine fitted—for example, Mandator 691. Mercury 505—is used.

Tractive Unit Probably the most important model, in view of the changes in regulations, is the Mandator which, for the U.K., is envisaged primarily as a tractive unit (if it is sold as a rigid goods it would have a gross weight rating of 16 tons, with heavier axles), and the engines offered are the AV 691 and 760. It is felt that with the gross power output of these engines-205 b.h.p. at 2,200 r.p.m. and 226 b.h.p. at 2,200 r.p.m. respectively and maximum torques of 573 lb. ft. at 1,200 r.p.m. and 618 lb. ft. at 1,500 r.p.m. respectively—the chassis will be somewhat overpowered in the eyes of British operators for use solo.

B40 It is because of this that it is likely that the tractive unit will have more appeal here. When exported as a rigid, the Mandator will be generally for use with a drawbar trailer. For both purposes it is designed for a maximum gross train weight of 32 tons.

In the tractive-unit form, wheelbase is 8 ft. The axle ratings at the ground are 5 tons for the front and 10 ton, for the rear, although the chassis is normally sprung for a front axle weight of 4 tons and rear axle weight of 9 tons. The AV 691 engine is standard with the AV 760 optional: in either case the drive is taken through an 18-in.-diameter hydraulically operated single-dry-plate clutch to the sixspeed overdrive gearbox used for some time on A.E.C. goods chassis. This has constant-mesh gearing, except for first and reverse (which are sliding mesh), and the ratio,: are 7-17, 4.45, 2-54, F53, 1 and 0.75 to J, with reverse 7-49 to 1. The front and rear axles are similar in general design to previously, with the double-reduction rear axle having spiral-bevel and double-helical drive and ratios of 5.68, 6.25, 7.08 or 7-89 are available. The brake units have, however, been changed, these continuing to be Girling. cam expanded, but the sizes have been increased and are now 15.5-in. diameter all Tound with 5-in.-wide front linings and 8-in.-wide linings at the rear. Total frictional area is 772 sq. in.

Brake operation is by air pressure with a 13.5-cu.-ft./min. twin-cylinder compressor driven in tandem on the engine with the fuel-injection pump. To provide an adequate handbrake performance to conform to the new regulations,

the handbrake is air-pressure assisted, with separate reservoirs for the footand hand-brake circuits. Triple diaphragm Clayton air chambers at the rear axle perform in a similar way to those on the A.E.C. passenger vehicles described last week. Application of the footbrake allows air behind one diaphragm, application of the handbrake air to the diaphragm farthest away, with the centre diaphragm ensuring that complete loss of air is avoided should one of the diaphragms fracture. • When the handbrake lever is operated, air is allowed into the handbrake section through a small valve located at the bottom end of the lever. A feature of the system is that, whilst air pressure is used to assist the handbrake application, the brake is held on mechanically through the ratchet at the handbrake lever.

Suspension is by semi-elliptic springs, 3 in. wide at the front and 3.5 in. wide at the rear with telescopic dampers at the front axle. And •the standard tyre equipment is 9.00-20, radial steel cord (single front and twin rear), although alternative tyres are 9.00-24, 10.00-20, I 1-00-20 or 11.00-22. Variations in the front and rear springs can be made according to particular axle loadings. The frame has a maximum section of 9.25 in. deep by 2-5-in. flanges, -and is *in. thick, and there is a drop at the front end to suit the cab that is to be fitted. Channel-section pressed-steel cross-members are .used and the frame assembly is of bolted construction. .

Rigid & Tractive Unit Models The new Mercury is offered as a rigid chassis with wheelbases of 12 ft. 1 in., 15 ft. and 18 ft., and also as a tractive unit with a wheelbase of 8 ft. The rigids are designed for a gross weight of 16 tons-6 tons front axle and 10 tons rear axle-whilst the tractive unit is suitable for maximum gross train weights of 24 tons, and in this case the axleratings are front 5 tons, rear 10 tons. The latter chassis is, however, normally sprung for a front-axle weight of 4-tons and a rear-axle weight of 9 tons, as with the Mandator. The general specification of the Me'rcurys is similar to the Mandator, the main _difference being that the AV 471 or .AV 505 engines are fitted instead of the larger units. The AV 471 engine is the standard unit, this producing a maximum power of 143 b.h.p. gross at 2,400 r.p.m. and a maximum gross torque of 368 lb. ft. at 1,000/1,200 r.p.m. The optional AV 505 produces a maximum output of 154 b.h.p. gross at 2,400 r.p.m. and maximum gross torque of 391 lb. ft. at 1,200/1,400 r.p.m. The clutch is a smallerdiameter unit than that on the Mandator with the larger engines, but the same six-speed overdrive gearbox with identical ratios is used.

Front Axles

The 5-ton front axle fitted on the tractive-unit version is naturally a little less robust than the 6-ton-capacity unit on the rigid version, the main difference being that the stubs are 2.5 in. diameter on the lighter and 2;46. in. diameter on the heavier. The standard rear axle on the lorry version is a single-reduction, spiral-bevel, fully floating unit available with ratios of 5.87 or 6.28 to I. Optional on this model is a double-reduction spiral-bevel/double-helicaldrive axle with ratios of 5.8, 6.27, 6.42 or 7.84 to I. This latter axle is the standard-fitting on the tractive unit with the single-reduction unit available as an option, in which case the gross-train-weight rating is reduced to 18 tons and, for special applications only, ratios of 4.08, 4-70 and 5.22 to I are offered.

The braking systems used on the two Mercurys are airpressure. operated and identical in design and layout-both foot and handbrake-to those on the Mandator. There is n4,

a difference, however, in the brake sizes, the tractive unit having 15.5-in. by 5-in, fronts and 15-5-in. by 7-in, rears, whilst the rigid has 15.5-in. by 6-in, fronts and 15.5-in. by 8-in. rears. Total frictional areas are 712 sq. in. and 832 sq. in. respectively. The suspension on the Mercury tractive unit is the same as on the Mandator tractive unit, but on the haulage model the front springs are 4 in. wide and the rears 3.5 in. wide, with the addition of helper springs. Hydraulic dampers are standard at the front axle of the lorry and optional on the tractive unit.

There is also a difference in the frame design; on the tractive unit the maximum section is 9-25 in. deep by 2.5-in.

flanges in. thick, whilst on the longer-wheelbase versions the maximum section is 10 in. deep by 3-in. flanges A in. thick;, on the 18-ft.-wheelbase model flitch plates are fitted. There is also a difference between the two Mercury designs in regard to tyres, these being 9.00-20 radia.1 steel cord on the tractive unit and I 1.00-20 radial steel cord on the rigid. Optional tyres are 10.00-20 on both versions and 11.00-20 as well on the tractive unit.

Alternative Marshal Bogies The Marshal six-wheeler is to be offered with a doubledrive or single-drive rear bogie (with four-spring suspension) and is available in three wheelbases. These are 10 ft. 8 in., 15 ft. 10 in. and 17 ft. 7.5 in. Axle ratings at the ground are 6 tons front and 16 tons rear bogie, and whilst it is designed to take a maximum gross weight of 22 tons, the 10-ft. 8-in.-wheelbase model is limited legally to 20 tons.

The standard engine in the Marshal is the AV 505 with. the AV 471 optional. The same 14-in.-diameter clutch and six-speed overdrive gearbox as in the Mercury are used and standard are the dduble-drive rear axles introduced early this year. They are single-reduction, spiral-bevel units with the through drive incorporating a lockable interaxle differential. , Axle ratios offered are 5.87, 6.28, 7.14 and 7-85 to 1. A single-drive bogie with a spiral-bevel driving axle is available, the ratios offered being 5.8, 6.27, 6-92 and 7.84 to 1.

Cain Brakes .

The front axle used is the same as the Mercury rigid, with 2-1-in. stubs and a 6-ton capacity. Girling camoperated brake-shoe units of the same size as the Mercury15.5 in. by 6 in.-are also used. At the rear, the Girling cam brakes are 15.5 in. by 7 in. at both axles, and these bring the total frictional area to 1,188 sq. in. Brake operation is identical to that on the Mercury modelsair-pressure , actuation, separate reservoirs for the footbrakes, and air-assisted handbrake and triple-diaphragm brake chambers at the rear axles.

Suspension is by 4-in.-wide leaf springs at the front axle and 3.5 in. at the rear, the pairs of springs on each side at the rear being interconnected by balance beams between them. Telescopic dampers are fitted at the front axle and the maximum section of the pressed-steel frame sidemembers is 12 in. deep with 3-in, top and bottom flanges, and the thickness of the material is 0-25 in, Radial-steel-cord tyres are used, the fronts being 10.00-20 for the 10-ft. 8-in.-wheelbase model and 11.00-20 for the other two lengths, and in all cases the standard rears are 9.00-20 twins; 10-00 or 11-00 can be supplied as options. As with the other models described, the electrical equipment includes a 5-in, alternator and the rest of the electrical system is the same.

There are two basic Mammoth Major eight-wheelers in the new introductions, one with four-spring rear suspension designed for a maximum gross weight solo of 28 tons and a maximum gross train weight with a drawbar trailer of 32 tons, the other with a two-spring rear bogie for the same gross solo but for a maximum gross train weight of 56 tons. Both basic versions have eight-wheel brakes and are offered in two wheelbases-14 ft. 5.5 in. and 17 ft. 2 in.

Taking first the version with four-spring rear suspension, the AV 691 11.3-litre diesel is standard, with the AV 760 optional. The engines drive through the same size clutch (18 in.) as on the Mandator to the six-speed overdrive gearbox as used on all the other models. The chassis is designed for axle ratings at the ground of 10 tons over the two front axles and 18 tons over the rear bogie—rear-axle spacing is 4 ft. 6 in. The two front axles are identical and are the 5-ton-capacity units with 2-5-in.-diameter stubs used on the Mercury and Mandator tractive units.

A singleor double-drive rear bogie is available, both employing double reduction, spiral-bevel/double-helical drive. On the double drive, where there is a lockable inter-axle differential, the ratios offered are 5.68, 6.25, 7.08, 7.89 or 9.04 to I. All these ratios except 9-04 to 1 are available on the single-drive version.

The braking system is similar to those on the other new models, with most components common. The main difference is that the two reservoirs for the footbrake and air-assisted handbrake are of a greater capacity. The wheel brake units are again Girling cam operated, 15-5 in. by 5 in. on the fronts and 15.5 in. by 8 in. on the rears.. Total frictional area is 1,544 sq. in.

Suspension is by 3-in.-wide leaf springs at the front with telescopic dampers at both axles. Still dealing with the

four-spring model, the rear suspension is a similar layout to the Marshal, with 3.5-in.-wide springs and springs on each side interconnected by balance beams at the shackles. The frame is of all-bolted construction with channelsection sideand cross-members. The side-members are -13-6in. thick and 12 in deep with 3-in. flanges. On the 14-ft. 5.5-in. wheelbase there is a -A--in.-thick channelsection flitch inside the side-members between the front and rear axles. A similar flitch is available on the longerwheelbase model as an option. Tyre equipment is 9.00-20 radial steel cord all round with alternative tyre sizes 9.00-24, 10.00-20 and 11.00-20.

The versions with a two-spring bogie are identical to the four-spring models with the exception of the rear suspension. . This follows previous A.E.C. design, being fully articulated, and uses 3-5-in.-wide inverted semi-elliptic leaf springs pivoting on a cross-tube mounted in substantial cast brackets. Torque reaction is transmitted by rubberjointed rods. There is no single-drive version of this model.

Similar Specifications There are also two basic Mammoth Major six-wheelers which have a generally similar specification to the eightwheelers except for the front axles and steering. The single front axle used has a load capacity of 6 tons and the model is designed for a 25-ton gross vehicle weight or when used with an independent trailer 56 tons, the same as the eight-wheeler.

On all the new models electrical equipment includes a 5-in, starter and a 5-in. alternator. A number of options to the standard mechanical specification of the chassis are offered. On the Mandator and single-drive Mammoth Major a heavy-duty rear-axle-drive unit with ratios of 5.85. 6.22, 7.12 or 7-92 to 1 is available, and on all models independent frontand rear-brake circuits, automatic chassis lubrication and an electrically operated exhaust brake can be specified.