The Measurement of Standards

Page 65

Page 66

Page 67

If you've noticed an error in this article please click here to report it so we can fix it.

By W. C. Wilson, M.INST.T.,M.I.R.T.E.

IN a sphere where inconsistency is the only consistent A factor, it has been of great interest to me to watch the smokemeter emerge as a practical piece of equipment which is employed in the workshops regularly by the men concerned with routine short-period maintenance as well as by the pump-shop staff. It is in fact a tool, not a toy; its use is as matter of fact as that of a steel rule or any other form of measurement, and the results convey suitable information to craftsmen and supervisors. I am well aware that the practicability of measuring exhaust-smoke density has been questioned by a number of knowledgeable engineers and indeed it would seem that some uncertainty is felt about dependability in varying conditions, which in turn has probably retarded the introduction of controls which must, however, eventually come into force.

I must admit that when first offered a Dunedin-Bosch Smokemeter for test purposes I was more than dubious, having seen a number of demonstrations of other types of meter and never found it possible to have confidence that my staff would accept and employ them as practical tools and believe that the results obtained truly reflected the condition of an engine. Today Smokemeter readings are quoted as evidence of work done, or needing to be done. Comparatively small variations are used to show that an adjustment or change of component has had an effect and sometimes a series of minor improvements, whilst on occasions they are used to establish that everything possible has been done and that only mechanical attention to the engine will secure a reading within the standard adopted for our own fleet.

An interesting aspect of workshop and management co-operation is that all concerned are able to visualize the state of exhaust condition from a number quoted. For example, if I reported to the workshop superintendent that I had seen one of our vehicles with an exhaust condition which 1 estimated at five he would regard this as serious and take the vehicle off the road; on the other hand if complained of one which he was able to say that he had tested and found a figure of two, which could not be improved upon, I should feel obliged to accept that situation.

The vital necessity for conducting an exhaust-smokecontrol campaign is the establishment of a standard which takes account of the characteristics of the engines operated and the mode of operation. There must be a figure adopted as a datum line which'can be achieved for most vehicles without excessively frequent attention or undue cost. The datum line itself is one that can be adjusted downwards as engine design and components improve, or as the domestic standard of maintenance is brought to a higher pitch. Readings above the datum line will impart their own degree of urgency according to tile number recorded or quoted. and in our own case, where the mechanical state of engines is usually known to all concerned with this aspect of our work, a high reading will by its number give my staff a good idea of where to look for a defect.

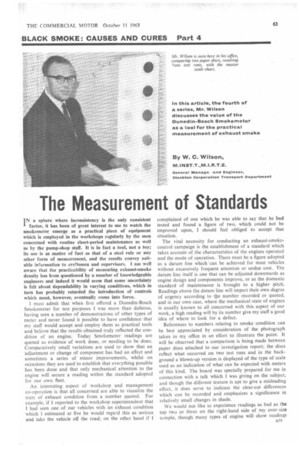

References to numbers relating to smoke condition can be best appreciated by consideration of the photograph taken in my office in an effort to illustrate the point. It will be observed that a comparison is being made between paper discs attached to our investigation report; the discs reflect what occurred on two test runs and in the background a blown-up version is displayed of the type of scale used as an indication of what can be expected with meters of this kind. The board was specially prepared for me in connection with a talk which I was giving on the subject, and though the different texture is apt to give a misleading effect, it does serve to indicate the clear-cut differences which can be recorded and emphasizes a significance in relatively small changes in shade.

We would not like to experience readings as bad as the top two or three on the right-hand side of my over-size sample, though many types of engine will show readings B39 like those on the bottom right-hand side unless the tightest control is exerted; other engines with characteristically better exhaust condition will be more akin to those in the middle, or even the top left-hand range (barely visible here).

The Smokemeter employs a white paper disc to record smoke level, and the degree of fouling is then defined with the aid of a meter which records on a scale variations from 0 to 10, with five sub-divisions between each pair of numbers, 0 representing the unsullied paper disc and a little under 6 the worst that we ourselves have ever experienced, Quite a number of our vehicles record less than 1; these are seldom checked except for comparisons and to keep a record on possible changes. A figure of 6 is high enough to justify public criticism and possibly police action, whilst anything below 1-5 may be considered very good.

At present we are endeavouring to deal with everything in excess of 1 This may sound high, but it is consistent with exhaust that shows obvious smoke under some conditions. The variables referred to by condition need clarification, but these will be dealt with in a later paragraph on the effects of engine temperature. Even minute differences can be readily detected, though quite often where components are changed, or adjustments made, very distinct changes in shade can be found; as, for example, where three test runs were made with remedial work between the first and second, and second and third, the results can be very clearly discerned.

The Smokemeter can be fitted and loaded in a few minutes and removed equally easily. The soiled discs can be handled without apparent adverse effect and we have records built up from such samples which I believe would satisfy the most critical inquirer, When necessary, it is quite simple for one man to carry out the test, as the Smokemeter can be operated from the cab. The description of operation will infer a vehicle in motion and this is in fact the manner in which the test must be carried out. The vehicle is brought to approximately 30 m.p.h., loaded by the application of the handbrake with the engine at about two-thirds of maximum r.p.m. and this is considered R reasonable simulation of load conditions.

It would be ideal if tests could be made on a free acceleration basis; that is to say in a standing position. B40 Experiments were conducted with this in mind, but the results conflicted wildly and were obviously not dependable. Since then reports have been made by several bodies with much better facilities than our own, and whose experience confirmed our findings that only road testing in controlled conditions will offer the reproducible results which inspire confidence.

During the year in which exhaust condition has concerned us so much, 114 observations have been made showing readings of 3 or more, and as such considered to need remedial action. Many more than this number will have been taken, but where they were below the present datum line they were of no consequence for our present purpose. Of the 114 recorded in the high category, 111 showed a reduction from an average of 4-03 to a final average of 2-17, with three showing no improvement and, though it is not an invariable result, there can be no doubt that in general fuel consumption will have been appreciably improved.

Smoke checks proved that 90 per cent of our problems were brought about by defective injectors, many of which —even after servicing by the manufacturer—were giving trouble in some form after less than 10,000 miles. Our thorough and detailed investigation of fuel injection equipment has satisfied us that it is most difficult to keep injectors set at the correct breaking pressure reasonably clean, injecting as sharply as intended, and with the correct spray form. The percentage and the mileage quoted would, I know, be considered a very poor figure for some types and makes of injector, and the figures offered are only intended to highlight the problem and act as a pointer to consideration of your own experience.

Work with the Smokemeter has been closely associated with the drive on fuel economy, and as road conditions are so variable and weather conditions have a profound effect on fuel consumption, it was necessary to try to evolve test conditions which would allow a standard to be set up against which performance could be judged. It could be considered that working conditions in heavy traffic form the best test for fuel consumption, but unfortunately it is extremely difficult to make tests of this kind with any regularity and on a repetitive basis, therefore it

is necessary for me to point out that all our tests have been • made over a 4-mile route which has no traffic controls and a low traffic density.

Vehicles are unladen, brought as close to normal operating temperature as possible, and we endeavour to use the same driver. Similar procedure has been followed for a very long time in connection with fuel tests, though until the Diestester was used in the workshops, and the Smokemeter on the road, the full importance of correct temperature had not been appreciated.

A report form is used in connection with all tests. It is set out in a manner calculated to suit our particular requirements and provides a complete history of any test, whether merely for black smoke or fully comprehensive where cylinder head and cylinder pressures, together with a full pump check, etc., are required. Consideration' of a number of completed forms, each with its own case history, emphasizes on one hand the worth-while results than can be achieved and on the other the difficulty in maintaining full efficiency over a long period.

Reference has been made to a considerable number of tests carried out, but the results of 20 undertaken on vehicles which had been the subject of complaints of excessively black exhaust may prove of interest. The worst showed a reading of 54, which was eventually reduced to F4, and our experience in this case was unusual, for there was no variation in m.p.g. The average Smokemeter reading of the 20 vehicles on the first check was 4.3; after adjustments and the changing of components where needed, the overall average was reduced to 2-2. The biggest reduction was from 4-7 to 1, and under the light test conditions fuel consumption improved by 7 per cent on the whole group.

No one likes unnecessary statistics, but in the first phase of an investigation and the collection of data which will facilitate the setting up of standards which can be achieved regularly and without undue cost on a fleet basis, it is without question necessary to record what is done, and in some cases to write a short history on the specially prepared report form so that progress from detection of an offensively high smoke level to its reduction to the minimum can be traced. Space will not permit the relation of a number of such histories, but details of one will I believe, justify attention.

The engine in question had run a high mileage without needing docking; its fuel and lubricating oil consumption were excellent, but Smokemeter readings were high, two being recorded at 4-4 and 4; imps. at this time was shown as 13.8. Injectors were checked, reconditioned in our own shops and refitted; m.p.g. over the light test run improved to 15 m.p.g., and the Smokemeter reading was reduced to 3. We were aware, however, that a control lever in the governor was worn and spares then in short supply were being awaited.

The next time the vehicle was tackled was when the new control lever was fitted and a smoke check showed a figure of 2-8, with the m.p.g. unchanged. This vehicle was part of an experiment to gain experience into the economics of this form of maintenance, and we were trying to ascertain what factors needed special consideration to raise fuel consumption to the highest possible level and reduce smoke to the lowest, therefore a set of injectors reconditioned by the manufacturer were fitted and the final test showed an m.p.g. figure of 15.8 and a Smokemeter reading of 0-8.

Early in our investigations we had sufficient evidence to justify discontinuation of comprehensive servicing of injectors in our own workshops. The standards which we could achieve compared very unfavourably with those of the manufacturer and the cost could quite easily have been appreciably higher. We have not been alone in reaching these conclusions, and some very large operators whose equipment for reconditioning could very well have been more elaborate than our own, which is the best that could be expected in a workshop of our size, have also decided that injector servicing is a specialized job to be carried out under closely controlled conditions. Prefitting tests of injectors supplied by the manufacturer justified some criticism and the standard of reliability under service conditions left much to be desired.

Communicating these facts to our supplier has, we believe, helped to bring about an improvement, and it cannot be over-emphasized that this is a component which is vitally important so far as design and repair standards are concerned. An improved type of injector supplied on vehicles delivered in recent years gives every promise of facilitating improved combustion and reducing calls for mainte n ance; some of these now run 50,000 miles and are

still satisfactory. I am convinced that injectors and injector condition are vital factors. T h e labour demand, the inconvenience of havir.,3 vehicles off the road, the cost in m.p.g. and the effect on exhaust condition—are such that no effort can be too great.

We could be questioned as to why we are prepared to accept the maximum figure of 3 as our standard, and the answer is probably as important a part of this report as any. By far the greater number of our vehicles are well below 3 and on new machines, in particular those fitted with the injector to which I have referred, it may be as low as 0-5. It will be our aim to reduce the datum figure as some of the problems outlined are overcome, though it is unlikely that there will be a startling reduction, at least until improved fuel injection equipment forms a higher percentage in our fleet. If, for example, a standard of 2 were imposed on the maintenance staff without long-term preparation, they would either fail to reach the target or there would be a greatly increased labour demand. We should also be approaching a point where possible economy was sacrificed in search of an ideal, whilst the results in terms of observable exhaust would not be readily apparent.

I remind readers that what may be considered a reasonable level on some makes of engine would be considered a high one on others.

Enough has been said on the subject of the Dunedin test equipment to suggest that it can offer information not otherwise readily available, and that it can be used by staff not specially skilled in its use. It is not fool-proof and reaches its maximum value in the hands of skilled staff who are using it regularly and are familiar with the interpretation of the figures offered, also the assessment of condition while the engine is running at normal working temperatures, for this we have found vitally important.

NEXT WEEK: The effects of overcooling.