Turbulent Oil Filtering as Producer-gas Medium

Page 33

If you've noticed an error in this article please click here to report it so we can fix it.

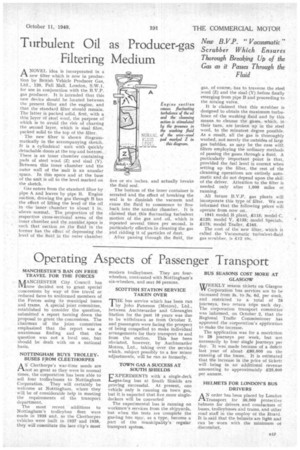

A NOVEL idea is incorporated in a new filter which is now in production by British Vehicle Producer Gas, Ltd., 120, Pall Mall, London, S'.W.1, for use in conjunction with the B.V.P. gas producer. It is intended that this new device should be located between the present filter and the engine, and that the standard filter should remain. The latter is packed solid, first, with a thin layer of steel wool, the purpose of which is to avoid the risk of charring the second layer, which is sisal fibre, packed solid to the top of the filter. The new filter is shown diagrammatically in the accompanying sketch. It is a cylindrical unit with quickly detachable doors at the top and bottom. There is an inner chamber containing pads of steel wool (Z) and sisal (Y). Between this inner chamber and the outer wall of the unit is an annular space. In this space and at the base of the unit is oil to the level marked on the sketch.

Gas enters from the standard filter by Pipe A and leaves by pipe B. Engine suction, drawing the gas through B has the effect of lifting the level of the oil in the inner chamber to about 1 in, above normal. The proportion of the respective cross-sectional areas of the inner chamber and the annular,space is such that suction on the fluid in the former has the effect of depressing the level of the fluid in the outer chamber

five or six inches, and actually breaks the fluid seal.

The bottom of the inner container is serrated and the effect of breaking the seal is to diminish the vacuum and cause the fluid to commence to flow back into the annular chamber, It is claimed that this fluctuating turbulent motion of the gas and oil, which is repeated several times per second, is particularly effective in cleaning the gas and ridding it of particles of dust. After passing through. the fluid, the gas, of course, has to traverse the steel wool (Z) and the sisal -(Y) before finally emerging from pipe B and proceeding to the mixing valve. It is claimed that this scrubber is designed to obtain the maximum turbulence of the washing fluid and by this means to cleanse the gases,which, in their turn, are broken up in the steel wool, to the minutest degree possible. As a result, all the gas is thoroughly washed, not merely the outsides of largt gas bubbles, as may be the case with filters employing the ordinary methods of passing the gases through a fluid. A particularly important point is that, provided the fuel level is correct when setting up the filter, the rest of the cleansing operations are entirely automatic and do not depend upon the skill of the driver. Attention to the filter is needed only after 1,000 miles ot running. All future B.V.P, gas plants will incorporate this type of filter. We are informed that the following prices will operate from now on. 1941 model B plant, £115; model -C, £120; model V. £135; model Specials, £175; model Trailer, £165. , The cost of the new filter,. which is called the Vacuurnatic turbulent-fluid gas scrubber, is El2 10s.